POF shrinkage film applicable to cold fresh chicken packaging

A technology of shrink film and cold fresh chicken, applied in the direction of synthetic resin layered products, layered products, chemical instruments and methods, etc., to achieve the effects of high-efficiency anti-pollution heat-sealing performance, excellent anti-fog performance, and excellent low-temperature heat-sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4 and comparative example 1

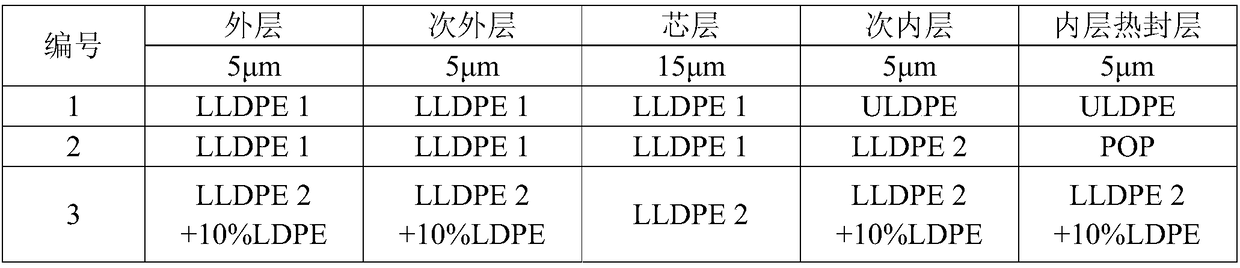

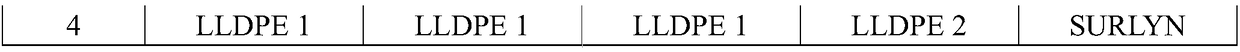

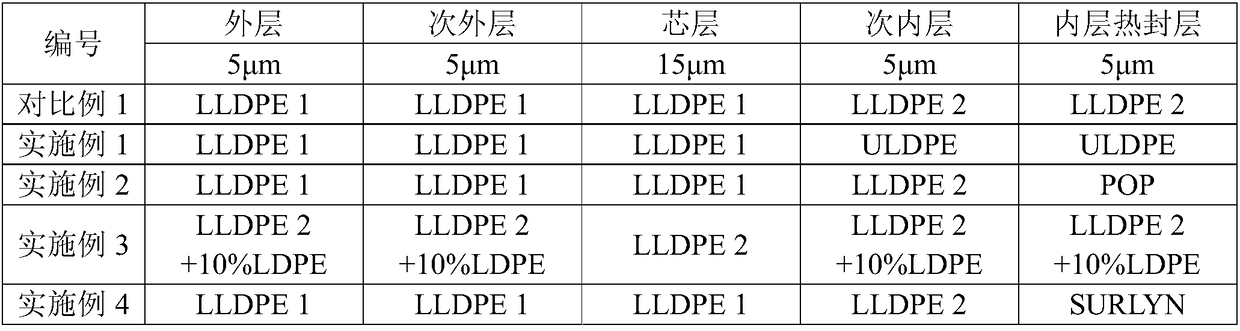

[0043] The shrink film structures of Examples 1-4 and Comparative Example 1 are shown in Table 1.

[0044] The production process includes the following steps:

[0045] S1: Put the raw materials in an extruder to co-extrude the film tube, and cool the film tube; the water temperature of the water cooling treatment in S1 is 5-15°C.

[0046] S2: Heat the cooled film tube to the preheating temperature, stretch the film tube, and then use compressed air for secondary inflation; the preheating temperature in S2 is 50-90°C; the inflation ratio of the secondary inflation is 3.5-6.5, the traction ratio is 3-6.5.

[0047] S3: Pull the film obtained by secondary inflation to the shaping mechanism, heat it again to the shaping temperature to shape the film, and finish the multi-layer co-extruded shrink film. The setting temperature in S3 is 30-70°C.

[0048] The shrink film structure of table 1 embodiment 1-4 and comparative example 1

[0049]

Embodiment 5

[0051] Performance test comparison:

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com