Polyester resin aqueous dispersion, coating film obtained from same, and packaging bag using such coating film

A technology of water-based dispersion and polyester resin, which is applied in transportation, packaging, thin material processing, etc. It can solve the problems of poor low-temperature heat-sealing performance, poor film-forming performance, and low adhesion, and achieve excellent low-temperature heat-sealing performance and utilization The effect of high value and excellent blocking resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

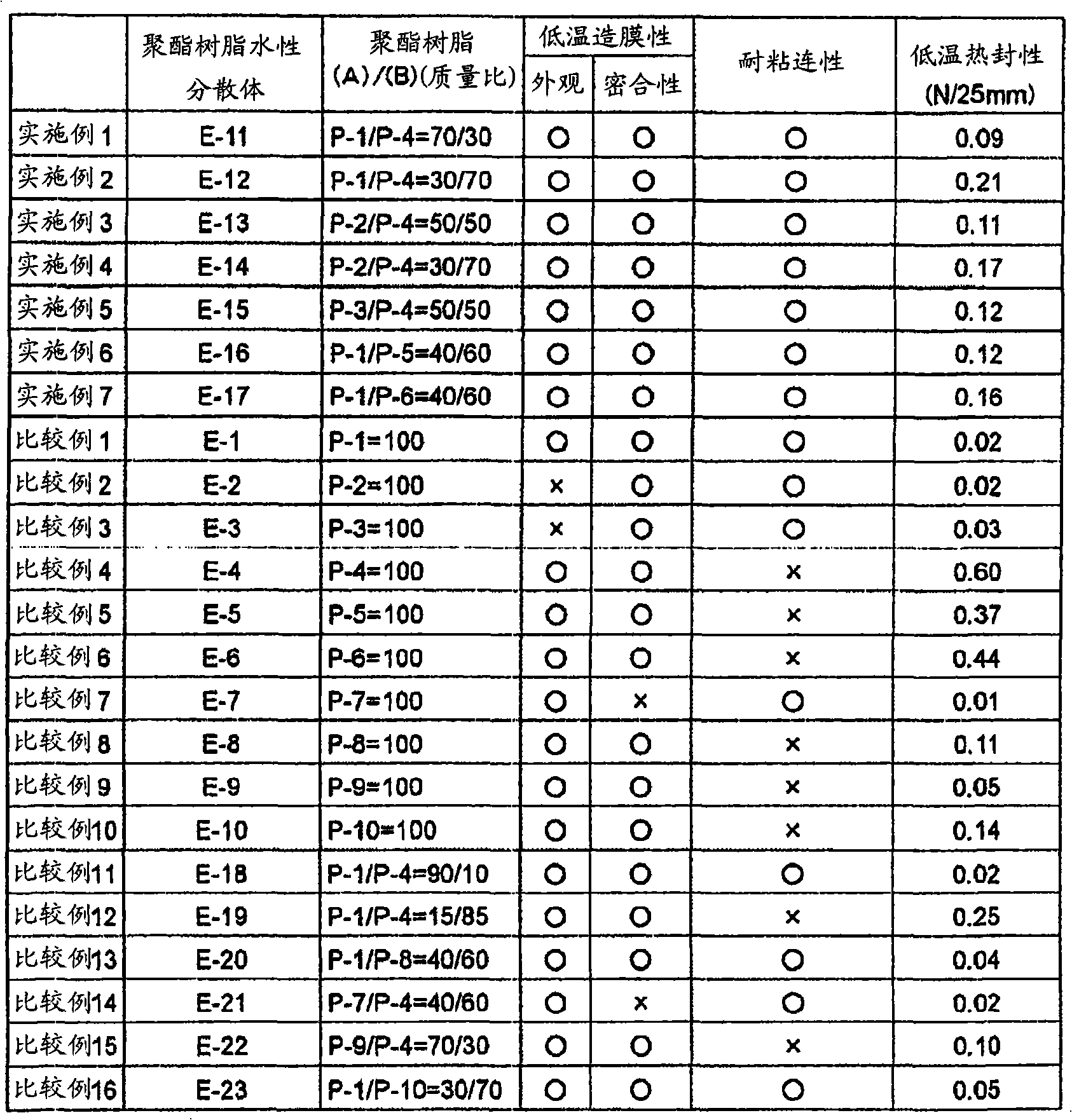

[0076] The present invention will be specifically described by way of examples below.

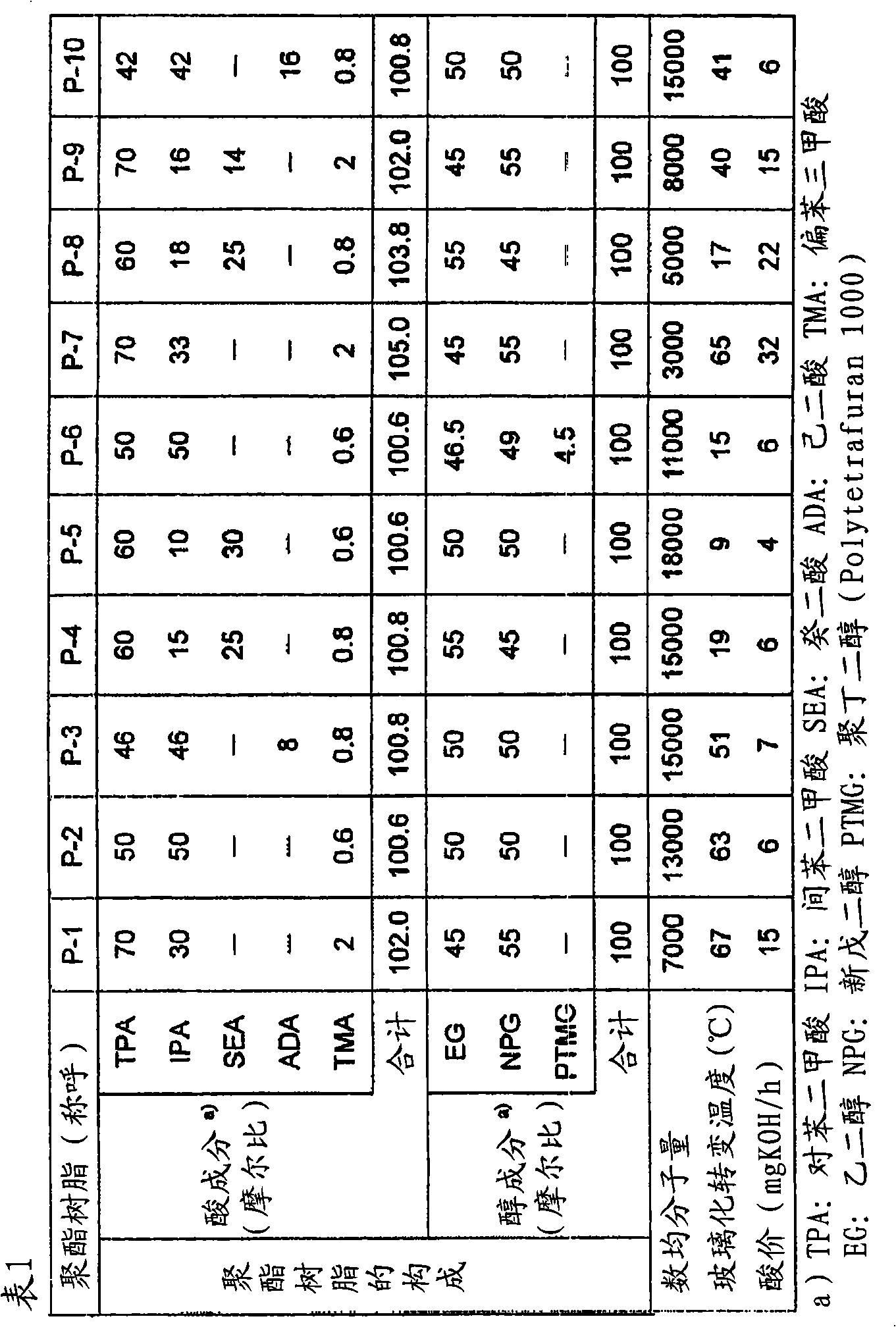

[0077] (1) Composition of polyester resin

[0078] It was obtained by 1H-NMR analysis (manufactured by Barian Corporation, 300 MHz). In addition, for resins containing constituent monomers for which no assignable and quantifiable peaks were seen in the 1H-NMR spectrum, methanolysis was carried out at 230° C. for 3 hours in a sealed tube, and then subjected to gas chromatographic analysis for quantitative analysis.

[0079] (2) Number average molecular weight of polyester resin

[0080] The number average molecular weight was determined by GPC analysis (Shimadzu liquid delivery unit LV-10ADvp and ultraviolet-visible spectrophotometer SPD-6AV, detection wavelength: 254 nm, solvent: tetrahydrofuran, polystyrene conversion).

[0081] (3) Glass transition temperature of polyester resin

[0082] Using 10 mg of polyester resin as a sample, it was measured using a DSC (differential scanning calo...

manufacture example

[0114] A mixture containing 1,911 g of terephthalic acid, 1,911 g of isophthalic acid, 292 g of adipic acid, 1,210 g of ethylene glycol, and 1,484 g of neopentyl glycol was heated in an autoclave at 240° C. for 4 hours to perform an esterification reaction. Next, 3.3 g of zinc acetate dihydrate was added as a catalyst, the temperature of the system was raised to 265° C., and the pressure of the system was gradually reduced to 13 Pa after 1.5 hours. The polycondensation reaction was continued under this condition, and after 4 hours, the system was brought to normal pressure with nitrogen gas, and the temperature of the system was lowered. After reaching 260° C., 38 g of trimellitic anhydride was added, stirred at 260° C. for 2 hours, and the depolymerization reaction was carried out. Thereafter, the pressure of the system was gradually reduced to reach 13 Pa after 30 minutes, and then degassing was performed for 1 hour. Then, the system was pressurized with nitrogen and extrude...

Embodiment 1

[0132] (Manufacture of polyester resin aqueous dispersion E-1)

[0133] 300 g of polyester resin P-1, 180 g of isopropanol, and 10 g of triethylamine were mixed using a stirrer with a jacketed 2-liter glass container that could be sealed (manufactured by Tokukikika Kogyo Co., Ltd., T.K. Robomix). . 510 g of distilled water was put into a glass container, and the stirring blade (homogenizer) was stirred at a rotational speed of 7000 rpm. Next, pass hot water into the jacket to heat, keep the temperature of the system at 73-75° C., and stir for 60 minutes. Thereafter, cold water was passed through the jacket, and the rotation speed was reduced to 5000 rpm to stir while cooling to room temperature (about 25° C.), and filtered with a 300-mesh stainless steel filter to obtain a polyester having an organic solvent content of more than 3% by mass. Aqueous resin dispersion. The dispersion is milky white and homogeneous.

[0134] Next, put 500 g of the polyester resin aqueous disper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com