Gas adsorption type inner-layer co-extrusion membrane for flexible packaging of lithium battery and preparation method of gas absorption type inner-layer co-extrusion membrane

A gas adsorption and flexible packaging technology, applied in packaging, wrapping paper, electrical components, etc., can solve the problems of poor air tightness of polypropylene film, short service life of lithium batteries, and damage of flatulence, so as to prevent gas failure and excellent toughness , good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

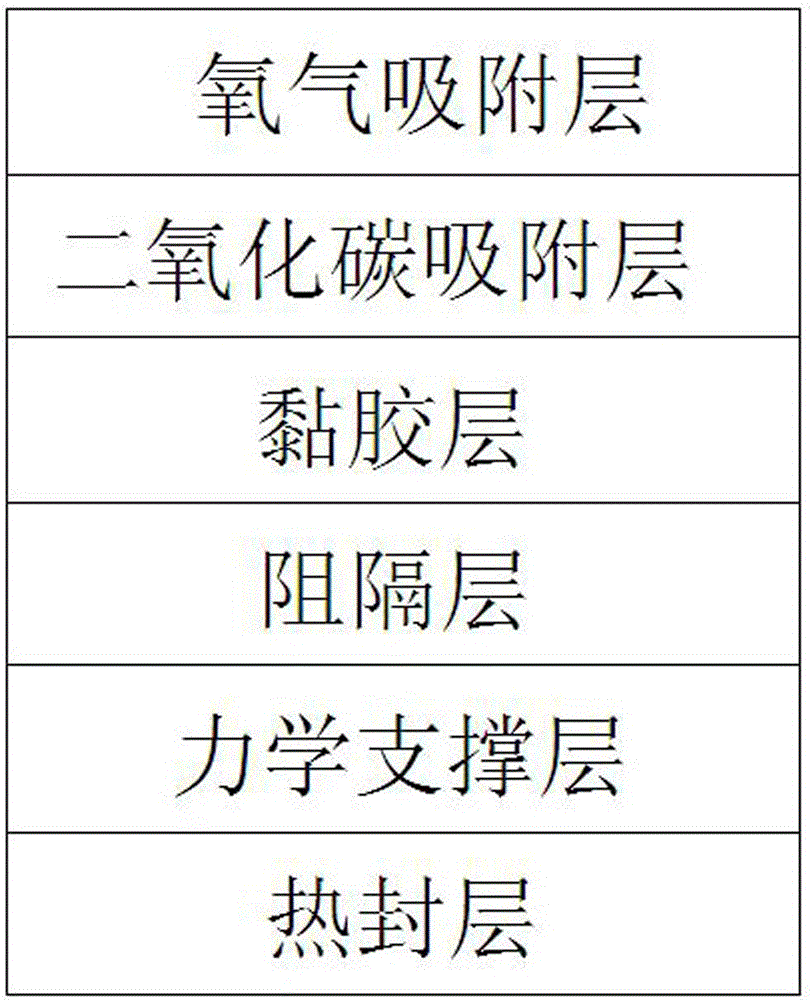

[0054] Such as figure 1 As shown, the gas-absorbing inner-layer co-extruded film for lithium battery packaging of the present invention is composed of a gas-absorbing layer, an adhesive layer, a barrier layer, a mechanical support layer, and a heat-sealing layer in sequence from outside to inside. The gas adsorption layer is composed of an oxygen adsorption layer and a carbon dioxide adsorption layer. in,

[0055] The oxygen adsorption layer contains the following raw materials in parts by mass:

[0056] 90 parts of polyethylene terephthalate;

[0057] 13 parts of hydroxyl-terminated polybutadiene / maleic anhydride ester oxygen absorber;

[0058] 0.1 part of cobalt acetate catalyst;

[0059] The carbon dioxide adsorption layer contains the following raw materials in parts by mass:

[0060] 95 parts of polyethylene terephthalate;

[0061] Metal-organic framework (MOFs) pumice-like imidazole-based framework material 0.5 part.

[0062] The adhesive layer is acid-modified po...

Embodiment 2

[0087] Such as figure 1 As shown, the gas-absorbing inner-layer co-extruded film for flexible packaging of lithium batteries of the present invention is composed of a gas-adsorbing layer, an adhesive layer, a barrier layer, a mechanical support layer, and a heat-sealing layer in sequence from outside to inside. The gas adsorption layer is composed of an oxygen adsorption layer and a carbon dioxide adsorption layer. in,

[0088] The oxygen adsorption layer contains the following raw materials in parts by mass:

[0089] 93 parts of polyethylene terephthalate;

[0090] 15 parts of 1,4-butenediol / maleic anhydride ester compound;

[0091] 0.08 part of cobalt acetate catalyst;

[0092] The carbon dioxide adsorption layer contains the following raw materials in parts by mass:

[0093] 92 parts of polyethylene terephthalate;

[0094] Metal-organic framework (MOFs) pumice-like imidazole-based framework material 1.6 parts.

[0095] The adhesive layer is acid-modified polyolefin a...

Embodiment 3

[0121] Such as figure 1 As shown, the gas-absorbing inner-layer co-extruded film for flexible packaging of lithium batteries of the present invention is composed of a gas-adsorbing layer, an adhesive layer, a barrier layer, a mechanical support layer, and a heat-sealing layer in sequence from outside to inside. The gas adsorption layer is composed of an oxygen adsorption layer and a carbon dioxide adsorption layer. in,

[0122] The oxygen adsorption layer contains the following raw materials in parts by mass:

[0123] 95 parts of polyethylene terephthalate;

[0124] 10 parts of 1,4-butenediol / methyltetrahydrophthalic anhydride esterified oxygen absorber;

[0125] 0.05 part of cobalt acetate catalyst;

[0126] The carbon dioxide adsorption layer contains the following raw materials in parts by mass:

[0127] 90 parts of polyethylene terephthalate;

[0128] Metal-organic framework materials (MOFs) 3 parts of pumice-like imidazole-based framework materials.

[0129] The ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com