Fast and efficient boron removal hollow fiber composite membrane and preparation method thereof

A fiber composite and hollow technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve problems such as polymer compatibility bottlenecks, and achieve the effect of simple method, easy cleaning, and efficient boron removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

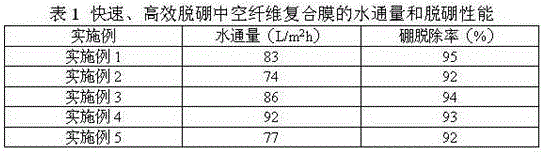

Examples

Embodiment 1

[0017] Embodiment 1 of the present invention: the preparation method of fast, high-efficiency boron removal hollow fiber composite membrane comprises the following steps:

[0018] 1) After cleaning the polymer porous membrane, seal both ends of the membrane;

[0019] 2) Take 1.5g of dopamine hydrochloride and 3.5g of polyethyleneimine with a molecular weight of 10,000, add them to 100 mL of Tris buffer with a concentration of 10mM, adjust the pH of the solution to 8.5, and obtain a dopamine / polyethyleneimine Tris buffer solution ;

[0020] 3) Immerse the polymer porous membrane cleaned in step 1) into the dopamine / polyethyleneimine Tris buffer solution obtained in step 2), take it out after magnetic stirring at 40°C for 10 h, wash with ethanol and deionized water (Share ethanol and deionized water?) (clean with deionized water first and then ethanol) to wash away the residual dopamine and polyethyleneimine, and prepare a DA / PEI modified hollow fiber composite membrane;

[00...

Embodiment 2

[0022] Embodiment 2 of the present invention: the preparation method of fast, high-efficiency boron removal hollow fiber composite membrane comprises the following steps:

[0023] 1) After cleaning the polymer porous membrane, seal both ends of the membrane;

[0024] 2) Take 1 g of dopamine hydrochloride and 4 g of polyethyleneimine with a molecular weight of 7000, add them to 100 mL of Tris buffer solution with a concentration of 10 mM, adjust the pH of the solution to 9, and obtain a dopamine / polyethyleneimine Tris buffer solution;

[0025] 3) Immerse the polymer porous membrane cleaned in step 1) into the dopamine / polyethyleneimine Tris buffer solution obtained in step 2), take it out after magnetic stirring at 30°C for 14 h, wash with ethanol and deionized water (Share ethanol and deionized water?) (clean with deionized water first and then ethanol) to wash away the residual dopamine and polyethyleneimine, and prepare a DA / PEI modified hollow fiber composite membrane;

[...

Embodiment 3

[0027] Embodiment 3 of the present invention: the preparation method of fast, high-efficiency boron removal hollow fiber composite membrane comprises the following steps:

[0028] 1) After cleaning the polymer porous membrane, seal both ends of the membrane;

[0029] 2) Take 3 g of dopamine hydrochloride and 2 g of polyethyleneimine with a molecular weight of 600, add them to 100 mL of Tris buffer solution with a concentration of 10 mM, adjust the pH of the solution to 8, and obtain a dopamine / polyethyleneimine Tris buffer solution;

[0030] 3) Immerse the polymer porous membrane cleaned in step 1) into the dopamine / polyethyleneimine Tris buffer solution obtained in step 2), take it out after magnetic stirring at 25°C for 4 h, wash with ethanol and deionized water (Share ethanol and deionized water?) (clean with deionized water first and then ethanol) to wash away the residual dopamine and polyethyleneimine, and prepare a DA / PEI modified hollow fiber composite membrane;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com