Hyaluronic acid modified surface plasma resonance spectrometer chip and preparation method thereof

A technology of surface plasmon and hyaluronic acid, applied in the direction of instruments, scientific instruments, material inspection products, etc., can solve the problem of high price of dextran series chips, and achieve the effect of high solid loading and high biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

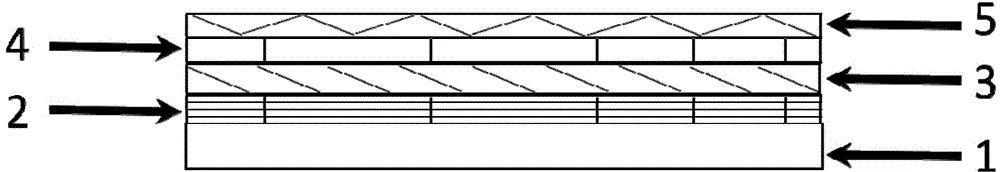

[0033] A 2nm-thick chromium layer was first coated on the BK7 glass substrate by vacuum sputtering, and then a 48nm-thick gold film or gold-silver alloy (mixed ratio) was coated to obtain a bare gold chip. Immerse the bare gold chip in a mixed solution of concentrated sulfuric acid and hydrogen peroxide (volume ratio 1:0.4) for 3 hours at room temperature. Then take it out, wash it with deionized water and dry it with nitrogen gas. The dried bare gold chip was immersed in 5 mM 11-mercapto-1-undecanol solution (prepared in ethanol) for 12 hours at room temperature. After cleaning with ethanol and deionized water and drying with nitrogen, immerse in 0.6M epichlorohydrin solution (prepared with diethylene glycol dimethyl ether), and soak for 4 hours at room temperature. After washing with deionized water and blowing dry with nitrogen, immerse in a hyaluronic acid solution (prepared with 0.1M sodium hydroxide solution) with a concentration of 1 mg / mL and a molecular weight of 10 ...

Embodiment 2

[0035]A 2nm-thick chromium layer was first coated on the BK7 glass substrate by vacuum sputtering, and then a 48nm-thick gold film or gold-silver alloy (mixed ratio) was coated to obtain a bare gold chip. Immerse the bare gold chip in a mixed solution of concentrated sulfuric acid and hydrogen peroxide (volume ratio 1:0.6) for 3 hours at room temperature. Then take it out, wash it with deionized water and dry it with nitrogen gas. The dried bare gold chip was immersed in 5 mM 11-mercapto-1-undecanol solution (prepared in ethanol) for 12 hours at room temperature. After cleaning with ethanol and deionized water and drying with nitrogen, immerse in 0.6M epichlorohydrin solution (prepared with diethylene glycol dimethyl ether), and soak for 4 hours at room temperature. After washing with deionized water and blowing dry with nitrogen, immerse in a hyaluronic acid solution (prepared with 0.1M sodium hydroxide solution) with a concentration of 3 mg / mL and a molecular weight of 1000...

Embodiment 3

[0037] A 2nm-thick chromium layer was first coated on the BK7 glass substrate by vacuum sputtering, and then a 48nm-thick gold film or gold-silver alloy (mixed ratio) was coated to obtain a bare gold chip. Immerse the bare gold chip in a mixed solution of concentrated sulfuric acid and hydrogen peroxide (volume ratio 1:1) for 3 hours at room temperature. Then take it out, wash it with deionized water and dry it with nitrogen gas. The dried bare gold chip was immersed in 5 mM 11-mercapto-1-undecanol solution (prepared in ethanol) for 12 hours at room temperature. After cleaning with ethanol and deionized water and drying with nitrogen, immerse in 0.6M epichlorohydrin solution (prepared with diethylene glycol dimethyl ether), and soak for 4 hours at room temperature. After washing with deionized water and blowing dry with nitrogen, immerse in hyaluronic acid solution (prepared with 0.1M sodium hydroxide solution) with a concentration of 10 mg / mL and a molecular weight of 2000 k...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com