Graphene oxide-recombined streptococcal protein G non-covalent composite material as well as preparation method and application thereof

A technology of recombinant streptococcus and composite material, which is applied in the field of chemical synthesis, can solve the problem of low amount of immobilized protein and the like, and achieve the effects of simple preparation steps, maintaining activity, and easy mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

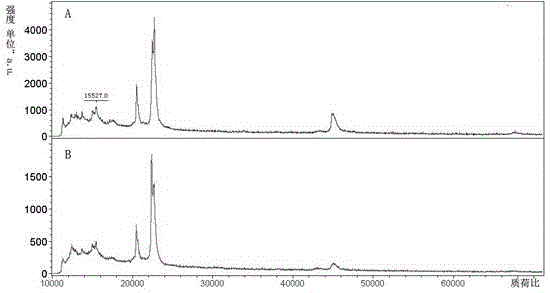

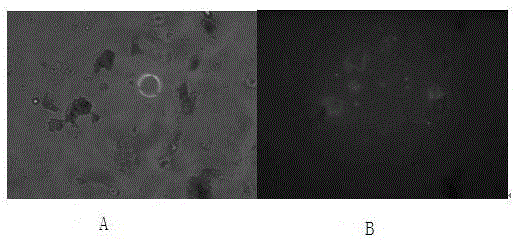

Image

Examples

Embodiment 1

[0019] (1) Activation of graphene oxide (GO)

[0020] 1. 1 mg GO was resuspended in 1 mL of deionized water, ultrasonicated at room temperature for 3 hours to fully disperse;

[0021] 2. Add 500 μL of 500 mM 2-(N-morpholino)ethanesulfonic acid 4-morpholineethanesulfonic acid (pH6.1) (MES), then simultaneously 16 mg / ml NHS 500 μL and 4 mg / ml EDC 500 uL, mix well, and stir rapidly at room temperature for 30 minutes;

[0022] 3. The material was washed repeatedly with 500mM (pH6.1) MES to remove residual NHS and EDC, and the final volume was 1mL;

[0023] 4. The solution is activated GO.

[0024] (2) Graphene oxide immobilized recombinant streptococcal protein G

[0025] 1. According to the ratio of 1:2.5, mix the material GO and PG prepared in the above (1) and incubate overnight at 4°C with shaking;

[0026] 2. Remove the supernatant after centrifugation at 16400×g / 10min, add 500mM (pH6.1) MES to wash three times, and the obtained material is graphene oxide-recombinant strep...

Embodiment 2

[0032] In the activation scheme of graphene oxide (GO), the concentration of NHS was changed to 24 mg / ml, and the others were the same as in Example 1, so that GOPG non-covalent composite material could be prepared.

Embodiment 3

[0034] In the activation scheme of graphene oxide (GO), the concentration of NHS was changed to 20 mg / ml, and the others were the same as in Example 1, so that GOPG non-covalent composite material could be prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fixed capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com