Method for preparing UiO-66 composite membrane material

A technology of uio-66 and composite membranes, applied in chemical instruments and methods, membranes, membrane technology, etc., can solve the problems of poor dispersion of MOFs membranes and poor stability of MOFs materials, and improve water stability and anti-pollution performance Good, strong pressure resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

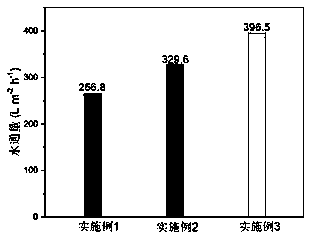

Embodiment 1

[0023] Example 1: The preparation method of the UiO-66 composite membrane material, the specific steps are:

[0024] (1) Dissolve zirconium tetrachloride and terephthalic acid in a mixture of N,N'-dimethylformamide and glacial acetic acid (the volume ratio of N,N'-dimethylformamide and glacial acetic acid is 5:4), ultrasonically stir at 25°C for 10min to obtain a mixed solution; transfer the mixed solution into the reaction kettle and react at 120°C for 12h; after the reaction kettle is cooled to room temperature, filter to obtain powder; use N, N'in turn -Wash three times with dimethylformamide and acetone, then three times with methanol, filter and vacuum dry at 100°C for 12h to obtain metal organic framework material UiO-66, in which the molar ratio of zirconium tetrachloride and terephthalic acid is 1 :2;

[0025] (2) Disperse the metal organic framework material UiO-66 in step (1) Tris buffer solution with pH=8.5, sonicate, then add dopamine, stir at room temperature for 24 h...

Embodiment 2

[0027] Embodiment 2: The preparation method of the UiO-66 composite membrane material, the specific steps are:

[0028] (1) Dissolve zirconium tetrachloride and terephthalic acid in a mixture of N,N'-dimethylformamide and glacial acetic acid (the volume ratio of N,N'-dimethylformamide and glacial acetic acid is 3:4) Stir ultrasonically at 30°C for 30min to obtain a mixed solution; transfer the mixed solution to the reaction kettle and react at 120°C for 24h; after the reaction kettle is cooled to room temperature, filter to obtain powder; use N, N'in turn for the powder -Wash three times with dimethylformamide and acetone, then three times with methanol. After filtration, dry under vacuum at 70°C for 18 hours to obtain metal organic framework material UiO-66, in which the molar ratio of zirconium tetrachloride and terephthalic acid is 1 :3;

[0029] (2) Disperse the metal-organic framework material UiO-66 in step (1) Tris buffer solution with pH=8, oscillate ultrasonically, then a...

Embodiment 3

[0031] Embodiment 3: The preparation method of the UiO-66 composite membrane material, the specific steps are:

[0032] (1) Dissolve zirconium tetrachloride and terephthalic acid in a mixture of N,N'-dimethylformamide and glacial acetic acid (the volume ratio of N,N'-dimethylformamide and glacial acetic acid is 6:4) Ultrasonic stirring at 25°C for 25min to obtain a mixed solution; transfer the mixed solution into the reaction kettle and react at 110°C for 18h; after the reaction kettle is cooled to room temperature, filter to obtain powder; use N, N'sequentially -Wash three times with dimethylformamide and acetone, then three times with methanol. After filtration, dry under vacuum at 80°C for 18 hours to obtain metal organic framework material UiO-66, in which the molar ratio of zirconium tetrachloride and terephthalic acid is 1 :4;

[0033] (2) Disperse the metal-organic framework material UiO-66 in step (1) in Tris buffer solution with pH=8.2, oscillate ultrasonically, then add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com