Filter material

A filter material and base material technology, applied in the field of filter material and air filter material, can solve the problems of filter material being too hard, low adsorption efficiency, no adsorption efficiency, etc., and achieve good adsorption performance, easy processing, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

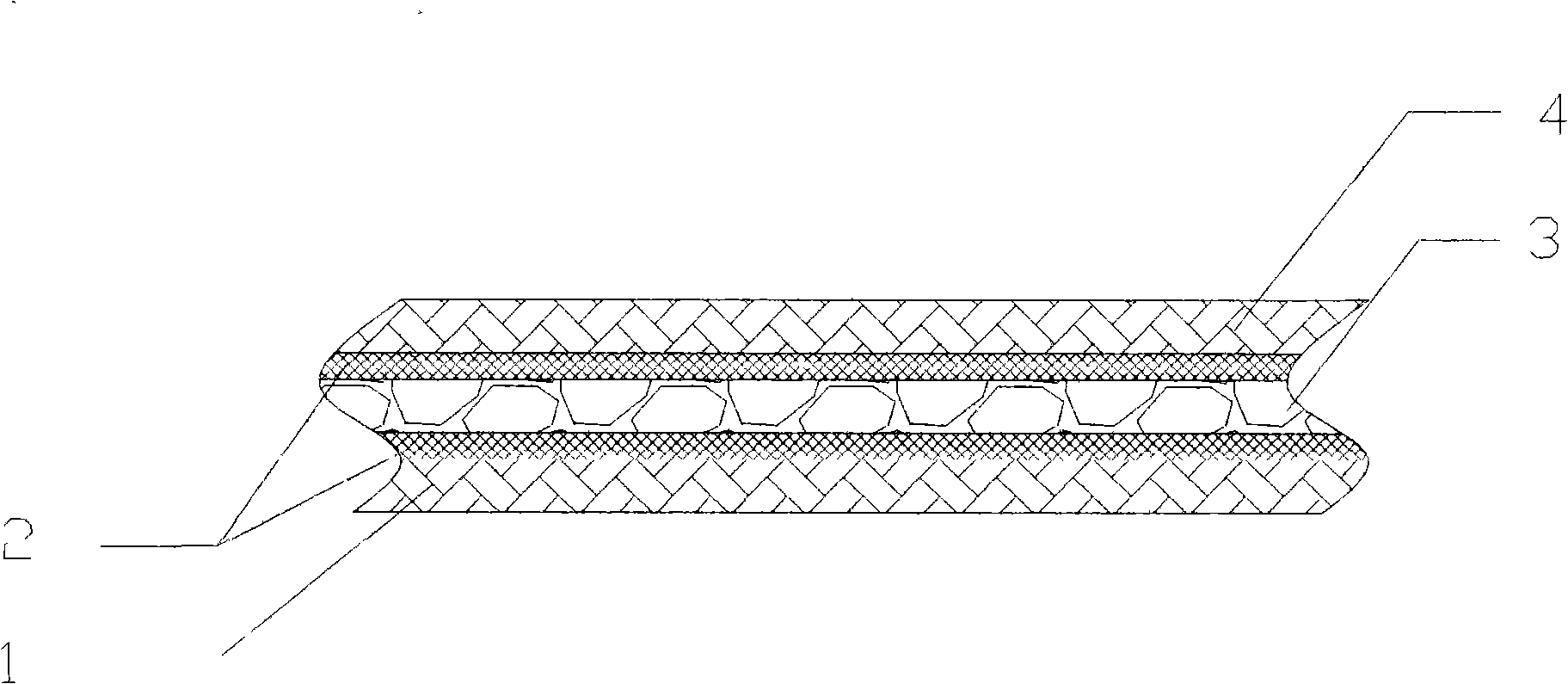

[0010] Example 1: figure 1 What is shown is a filter material with only one composite layer between two layers of non-woven fabrics 1 and 4. First, the non-woven fabric 1 is coated with a layer of fibrous adhesive 2, and then 40-80 mesh activated carbon particles are sprinkled on the fibers. Granular activated carbon layer 3 is spread on the granular activated carbon layer 3, and then a layer of fibrous adhesive 2 is coated on the granular activated carbon layer 3, and the granular activated carbon layer 3 is wrapped between two layers of fibrous adhesive 2 to form a composite layer, and finally compounded Non-woven fabric 4 gets final product.

Embodiment 2

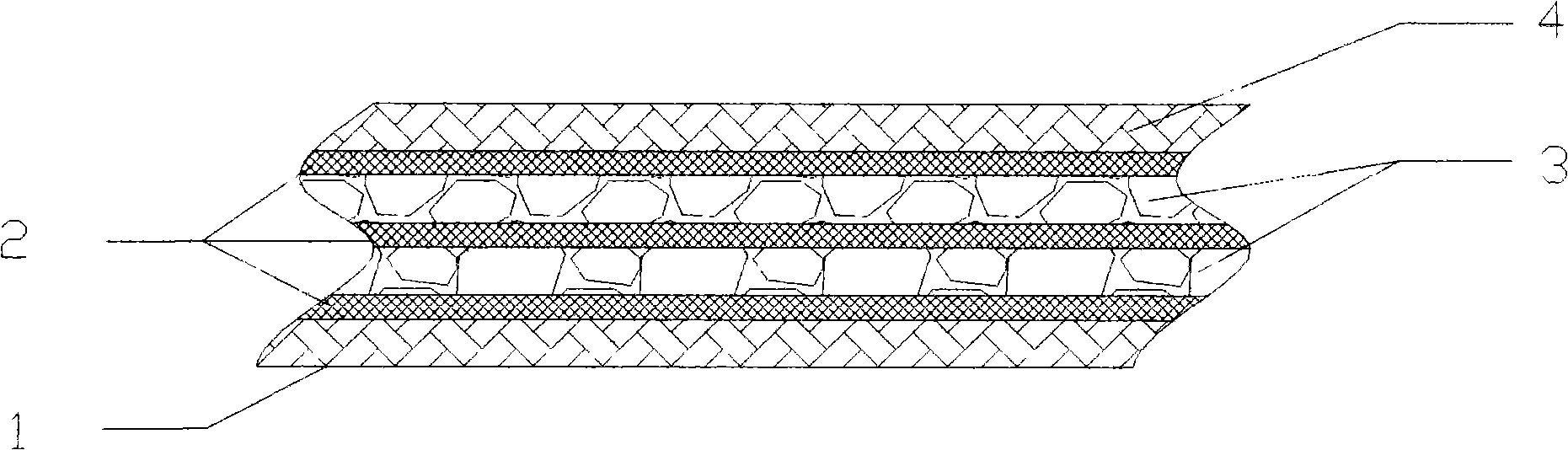

[0011] Example 2: figure 2 Shown is a filter material with two composite layers between two layers of non-woven fabrics 1 and 4. First, the non-woven fabric 1 is coated with a layer of fibrous adhesive 2, and then 40-80 mesh activated carbon particles are sprinkled on the filter material. Spread the first granular activated carbon layer 3 on the fibrous adhesive 2, then coat a layer of fibrous adhesive 2 on the granular activated carbon layer 3, and sprinkle 40-80 mesh activated carbon particles on this layer of fibrous adhesive 2. The second granular activated carbon layer 3 is formed, and a layer of fibrous adhesive 2 is coated on the second granular activated carbon layer, and the two granular activated carbon layers are respectively wrapped between two layers of fibrous adhesive to form a double composite layer. Non-woven fabric 4 gets final product.

[0012] The above-mentioned filter materials are combined with fibrous adhesives, which will not block activated carbon p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com