Active carbon producing process with mixed stalk material

A technology for producing activated carbon and mixing raw materials, applied in the field of activated carbon production, can solve problems such as slow development, and achieve the effects of quick effect, high income and small investment scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

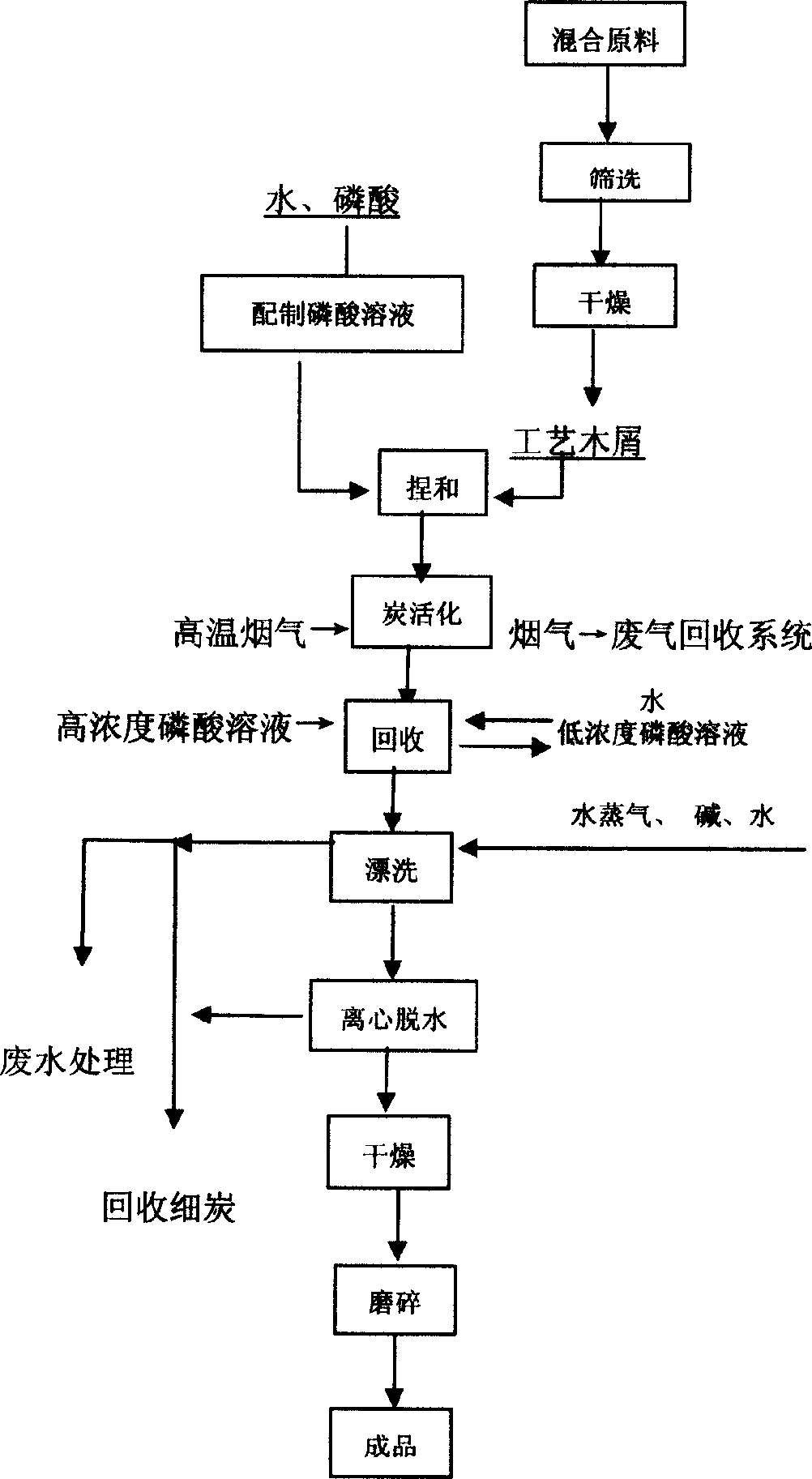

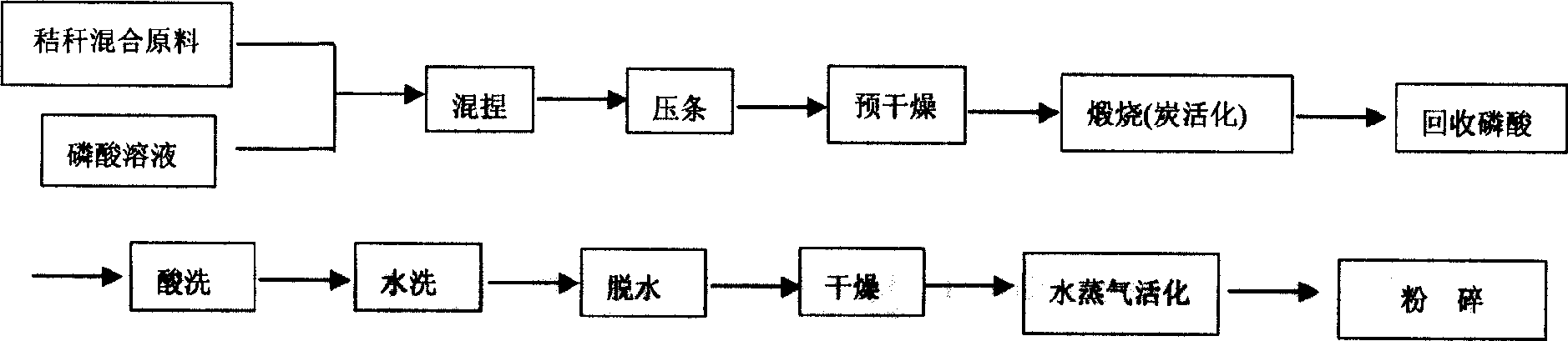

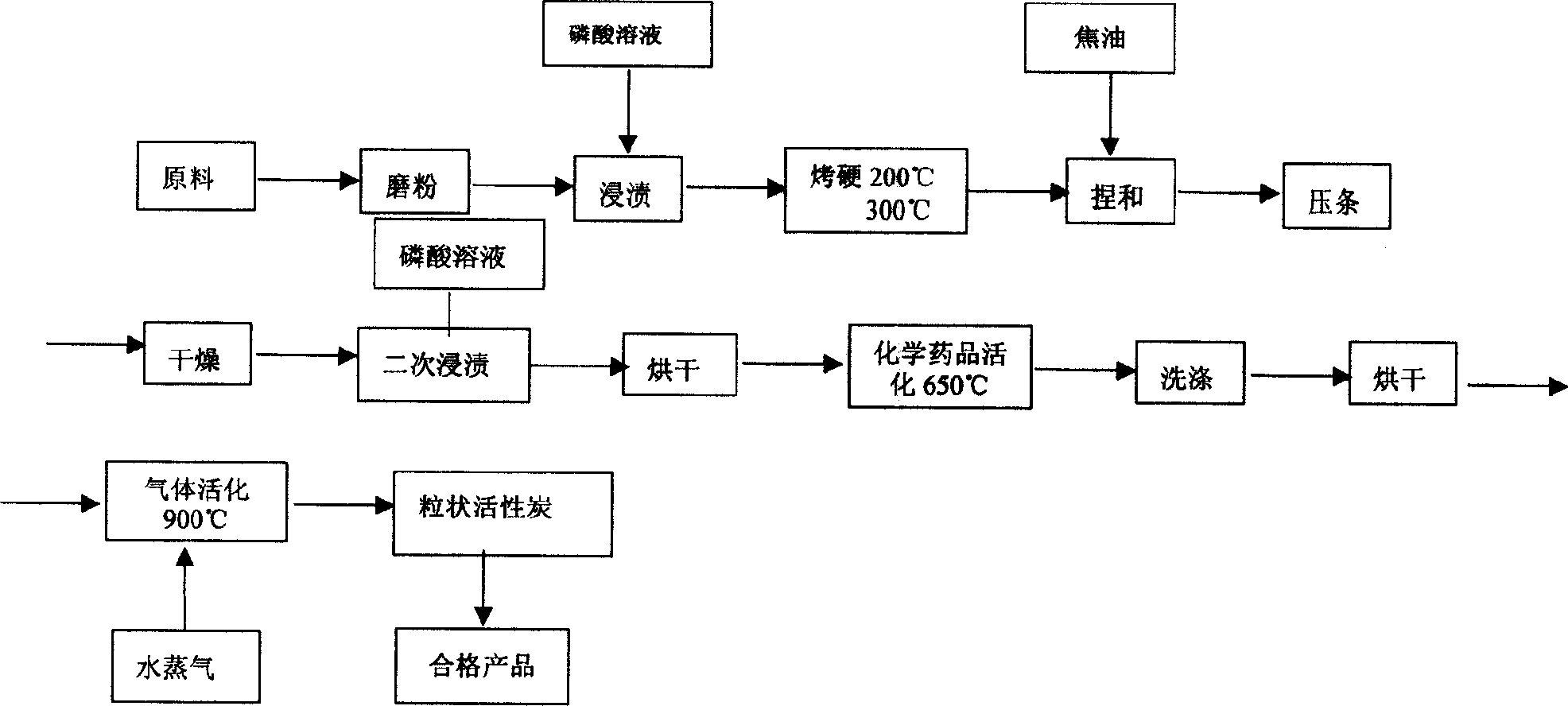

[0103] Example 1: Production process of straw mixed raw material activated carbon

[0104] In this embodiment, crop stalks are mixed in a certain proportion, the mixed raw materials of crop stalks, fruit tree waste branches, and tree sawdust are in a ratio of 1:1:1, and the stalks are cotton stalks, wheat stalks, and corn stalks to produce powdered activated carbon. Such as activated carbon for sugar, activated carbon for injection, activated carbon for pharmaceuticals, monosodium glutamate decolorization, medicinal activated carbon, reagent activated carbon, etc. Through practical research, the combination of phosphoric acid activation method and physical method can also produce granular activated carbon.

[0105] 1. Production of powdered activated carbon by phosphoric acid method

[0106] 1.1 Process flow

[0107] The process flow for producing powdered activated carbon is shown in the appendix Figure 1~3 Generally, it includes three parts: pretreatment, carbonization a...

Embodiment 2

[0171] Example 2: Production of activated carbon by straw environmental protection physical and chemical combination method

[0172] In this example, an activated carbon sample with better performance was developed by using crop straw (mixed) as raw material, using potassium hydroxide as an activator, and through acid pretreatment and steam activation. Experiments show that the optimum temperature for activity is 750°C-800°C, the optimum heating rate is 5°C / min-10°C / min, and the optimal dosage of activator is 1:1 (mass ratio of raw material to activator). The iodine adsorption value of the activated carbon sample is 980mg / g, and the specific surface area is 1180m 2 / g. At the same time, the activation mechanism of KOH was discussed. The wide application of activated carbon makes the development of activated carbon have certain significance. One of the main research directions of straw activated carbon.

[0173] Different types of crop straw have different basic structural ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| iodine adsorption value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com