Multifunctional detachable type double-impeller rotary air locking valve device

A lock air valve, split technology, applied in the direction of rotary conveyor, transportation and packaging, conveying bulk materials, etc. problems, to achieve the effect of convenient replacement and maintenance, large discharge processing capacity, and large material capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with embodiments, and the purpose is only to better understand the content of the present invention. Therefore, the examples cited do not limit the protection scope of the present invention.

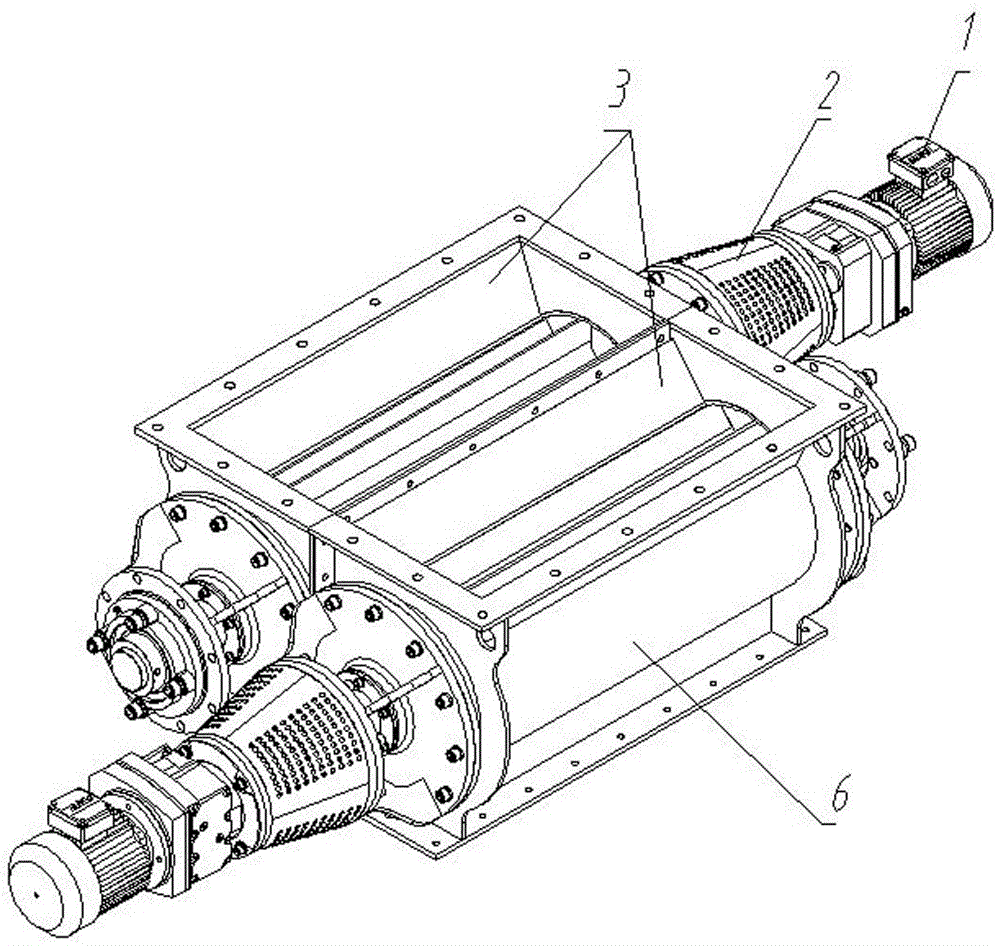

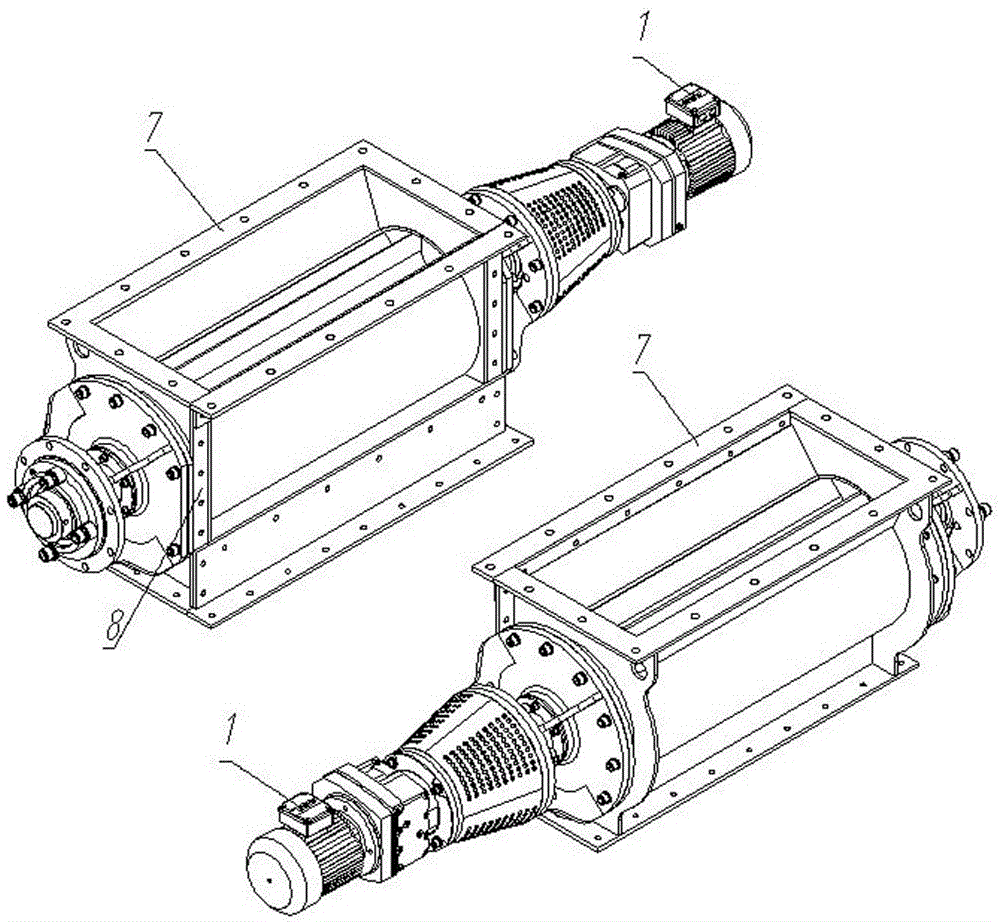

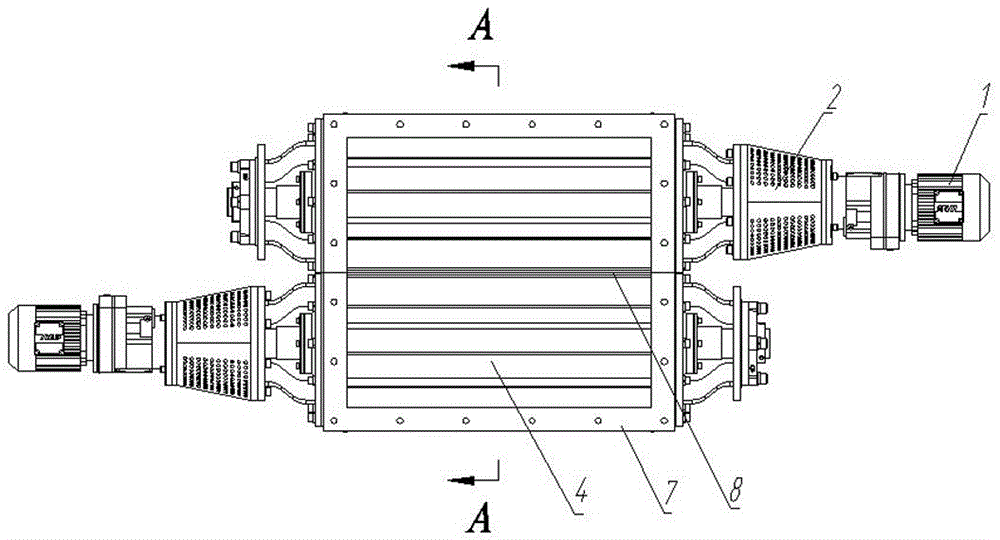

[0025] See figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Including two rotary air lock valves, the two rotary air lock valves are symmetrically arranged and connected by a connecting flange as a whole; each rotary air lock valve includes a power drive device 1, an elastic coupling 2, a housing 6, Impeller, the impeller includes a rotor 5 and blades 4. The power drive device 1 is connected to the rotor 5 through an elastic coupling 2 to control the rotation of the rotor 5. A plurality of blades 4 are fixed around the rotor 5, and the casing 6 is mounted on the impeller 4 On the periphery, every two blades 4 and the casing 6 form a cavity, and the upper and lower ends of the casing 6 are respectively provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com