Crankshaft rotary type high-speed bidirectional oscillation stirring robot

A crankshaft rotation and robot technology, which is applied to mixer accessories, shaking/oscillating/vibrating mixers, mixers, etc. The mixing effect is good, the material is fully stirred and dispersed, and the strength is guaranteed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, and the implementation scope of the present invention is not limited thereto.

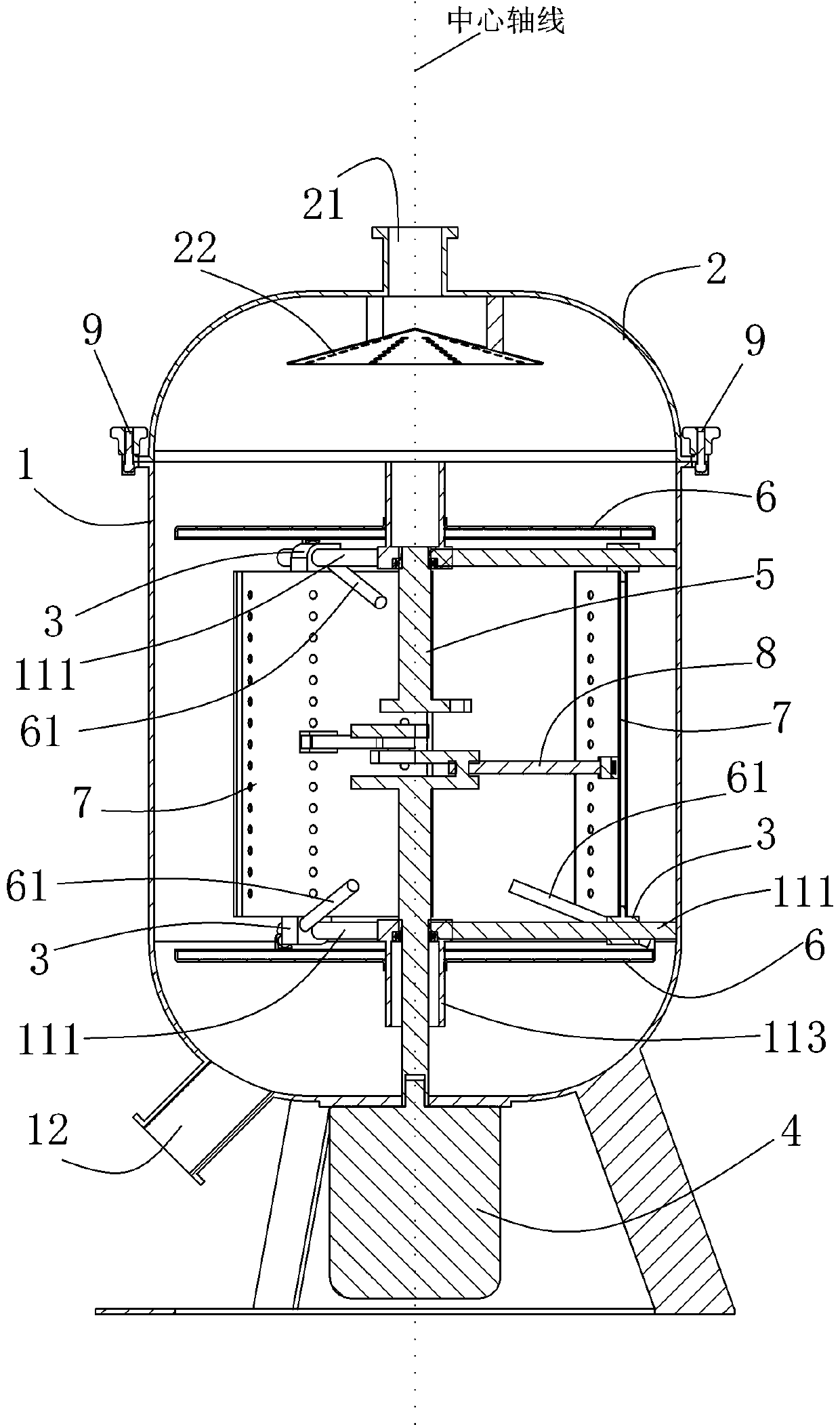

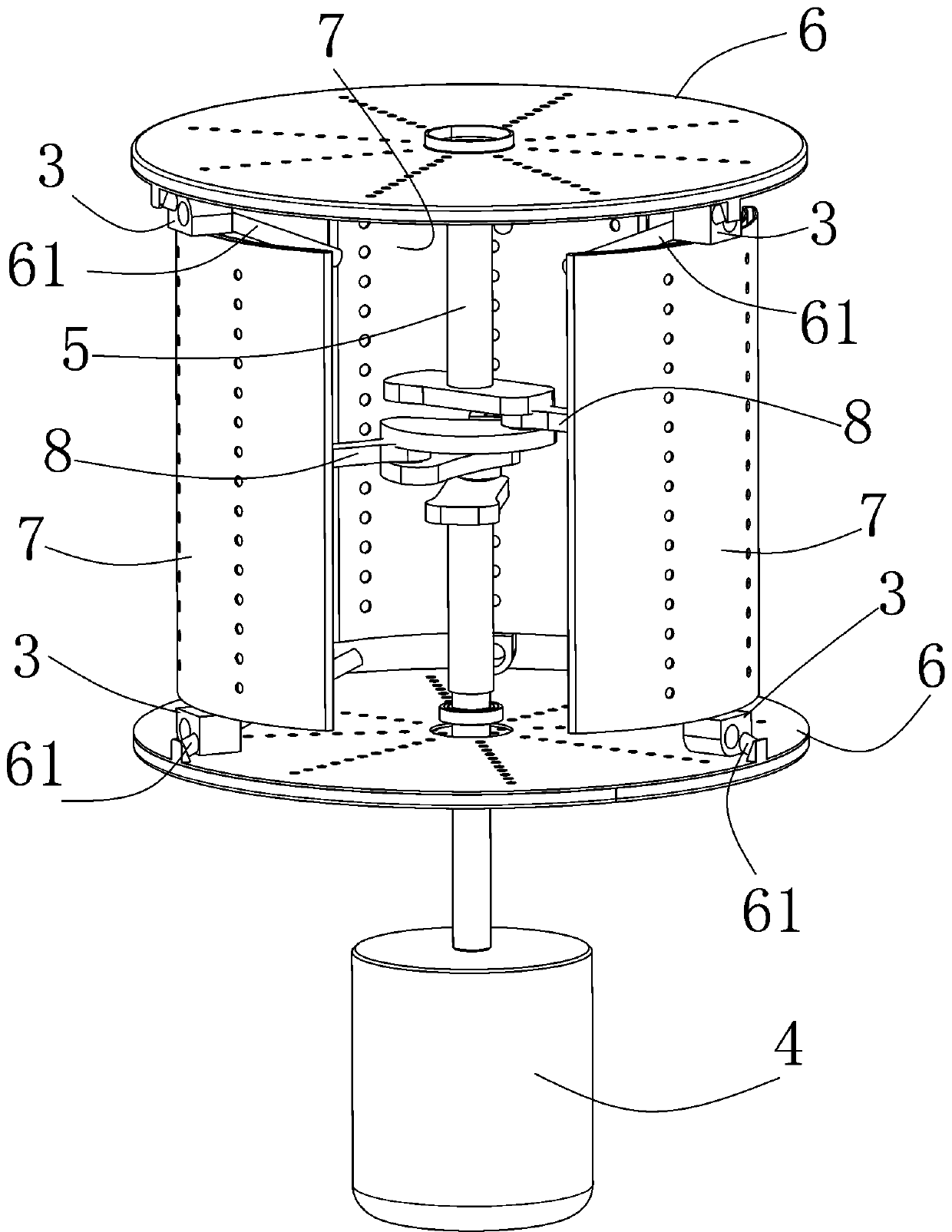

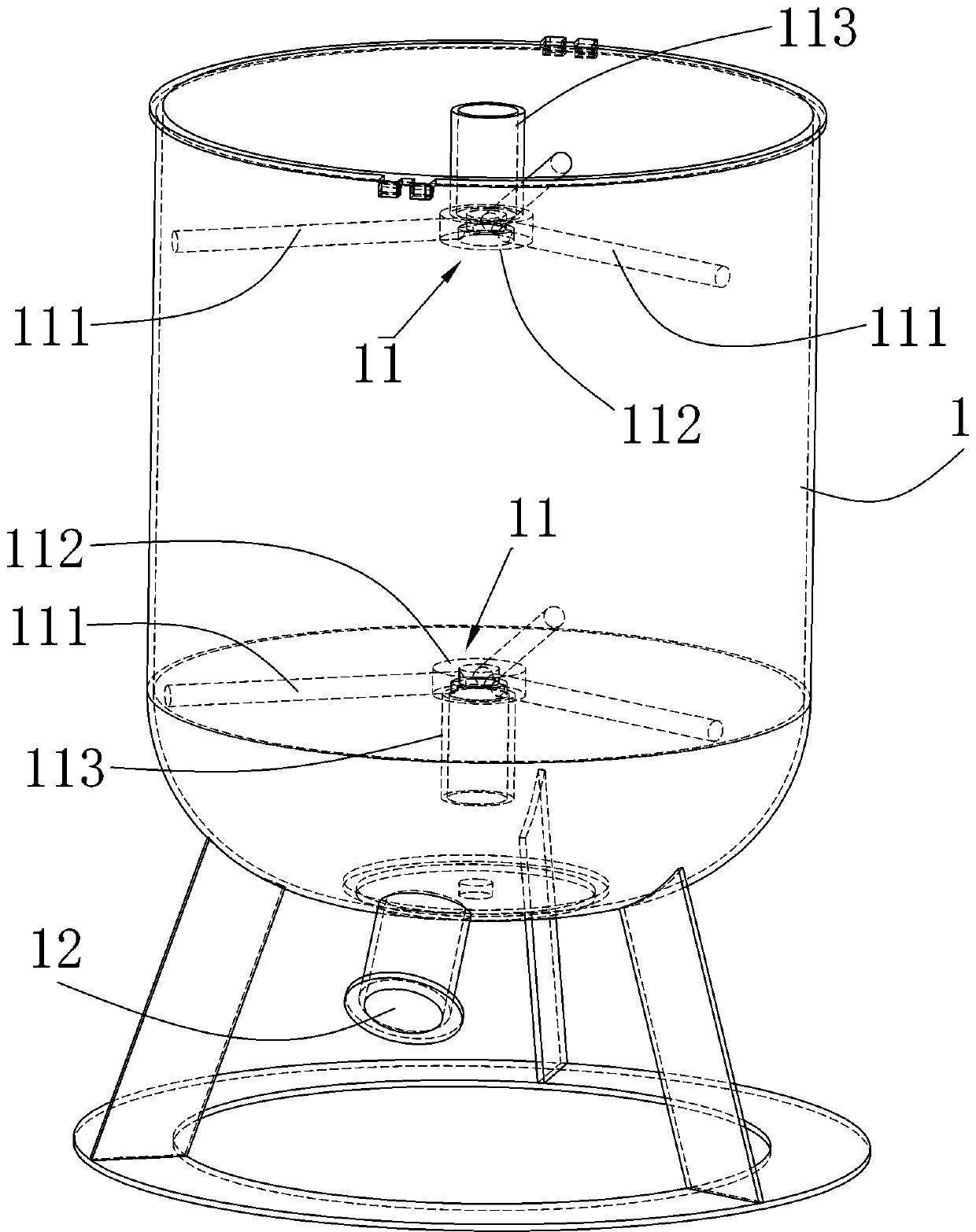

[0023] Such as Figure 1 to Figure 5 As shown, a crankshaft rotary high-speed two-way oscillating stirring robot described in this embodiment includes a tank body 1 and a top cover 2, and the top cover 2 is detachably connected to the top of the tank body 1, which is convenient for opening and maintenance operations. The top cover 2 is provided with a feeding port 21 and a feeding dispersing screen 22, the feeding dispersing screen 22 is located below the feeding port 21, and the inner wall of the tank body 1 is provided with two groups of upper and lower symmetrically arranged and The guide frame 11 that is center-radiating makes the strength of the tank body 1 higher. The guide frame 11 includes three equally spaced transverse guide rods 111 and a central ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com