Flow monitoring type non-return flap apparatus

A technology of non-return door and flow, which is applied in the direction of valve device, function valve type, transportation and packaging, etc. It can solve the problems of polluting the environment, the inability to adapt to the positive pressure dense phase pneumatic ash conveying system, and the increase of ash content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

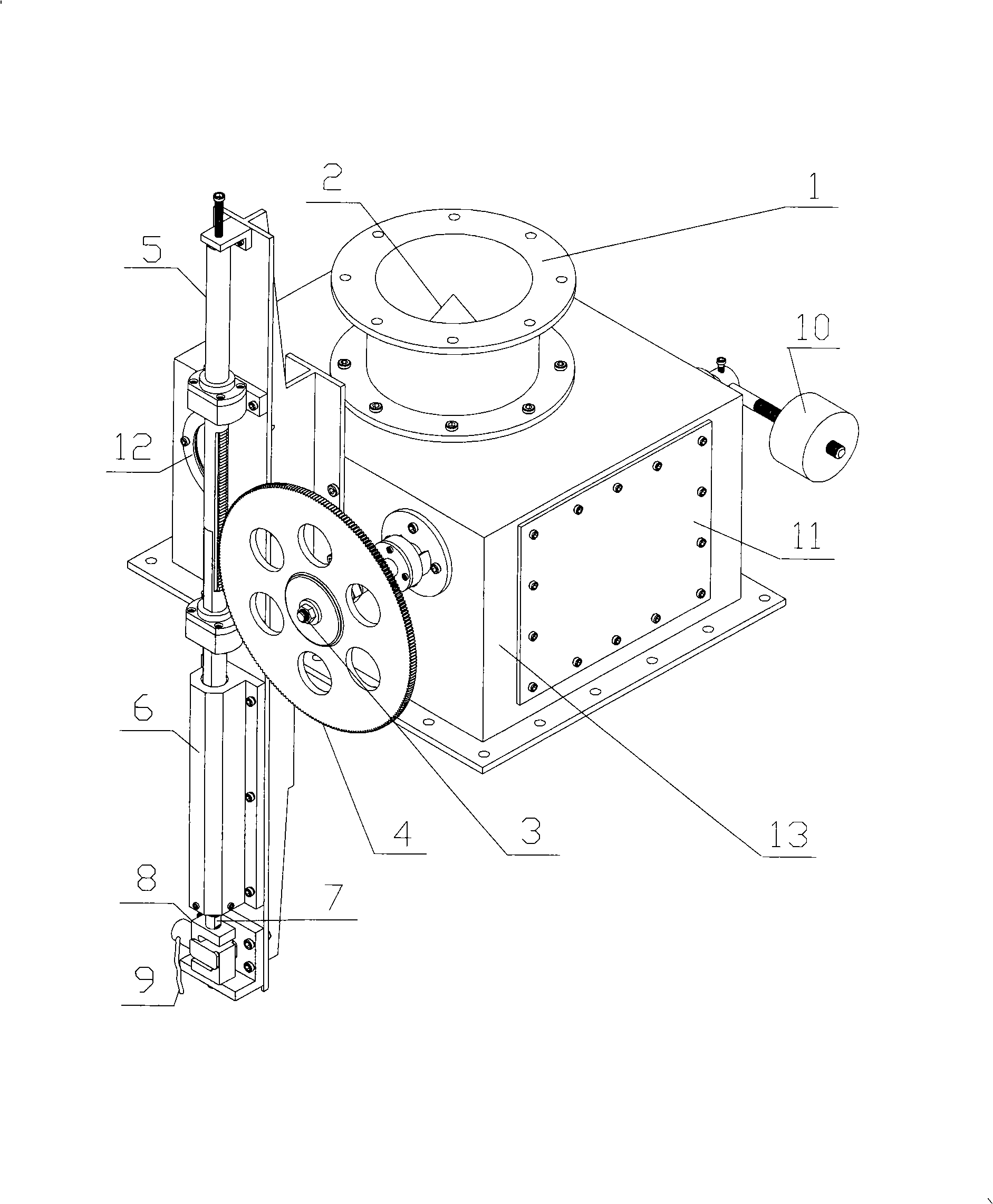

[0010] In the figure, when the fly ash is scattered from the ash falling pipe (1) of the flow-monitoring check valve device to the cone cap (or ball valve) (2), the gravity of the fly ash produces a rotating weight on the door shaft (3) The torque causes the gear (4) to rotate to drive the rack bar (5) to move linearly, and the force is transmitted to the rectangular coil spring in the spring sleeve (6) to produce compression and deformation, and its compression force is the same as the conical cap (or ball valve) end The generated moments are balanced. When the lengths of the arms at both ends are equal, the compression force generated by the rectangular coil spring's compression deformation is equal to the gravity of the fly ash conveyed by the cone cap (or ball valve) end. The flow monitoring type check door device realizes its function through the principle of torque balance. The flow monitoring type check door device is characterized by including: an ash tube (1) installed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com