Feeding device for boards of various specifications

A multi-specification, plate technology, used in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problem of unable to achieve the sequential supply and precise positioning of different plates, and achieve easy movement of the drive rack and a wide range of applications. , the effect of high resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

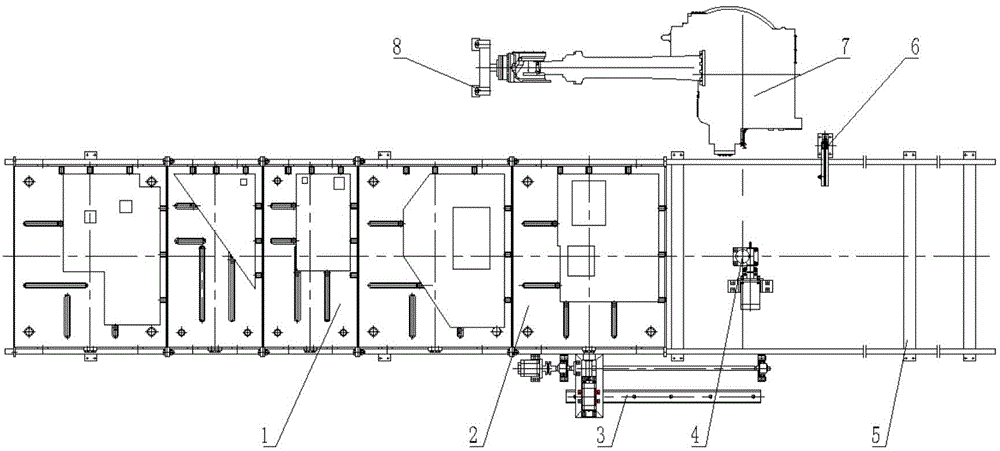

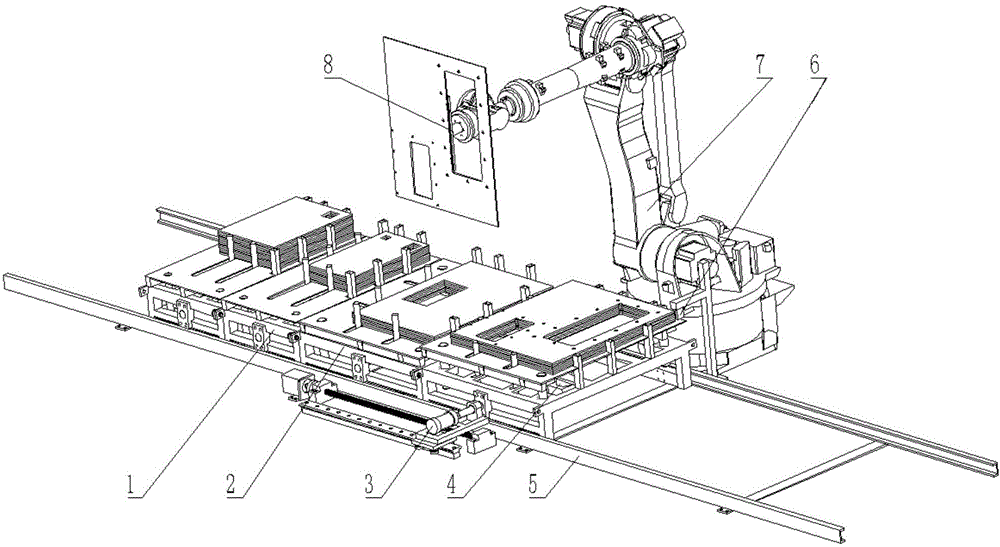

[0028] Example Figure 1-4 As shown, a plate feeding device includes two conveying guide rails 5 arranged in parallel, several large plate material warehouses 2 and small plate material warehouses 1 assembled on the conveying guide rails 5, and a stepper installed on one side of the conveying guide rails 5. The feeding mechanism 3, the feeding manipulator 7 installed on the other side of the conveying guide rail 5 and the sensor frame provided with the sensor 6, the jacking device 4 placed in the middle of the conveying guide rail 5, and the electromagnetic chuck 8 installed on the head of the feeding manipulator 7 . The jacking device 4 is at the reclaiming position of the feeding manipulator 7, and the jacking device 4, the feeding manipulator 7 and the non-motor end of the stepping mechanism 3 are in a straight line.

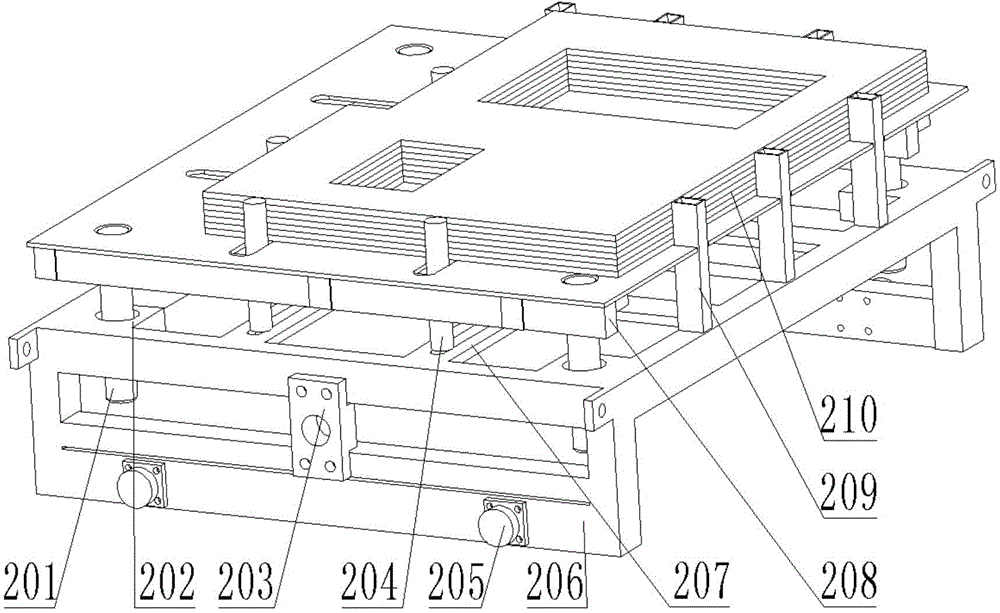

[0029] The feed bin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com