A non-clogging stacking mechanism for drug blister plates and its application method

A blister board, non-blocking technology, applied in the stacking, packaging, packaging protection of objects, etc., can solve the problems of height difference, blockage, etc., and achieve the effect of reducing the probability of rollover, avoiding blockage, and facilitating later maintenance and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

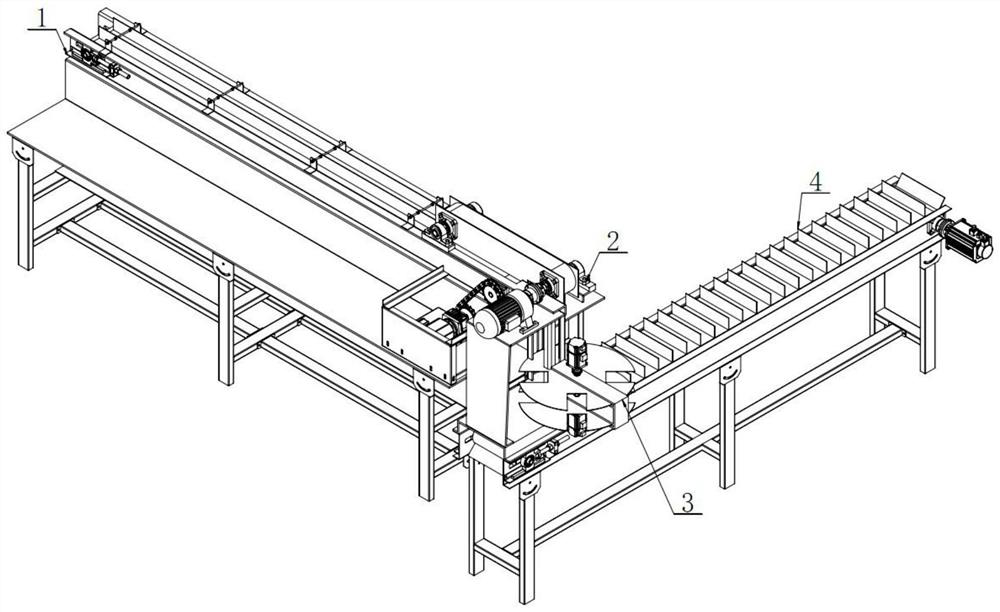

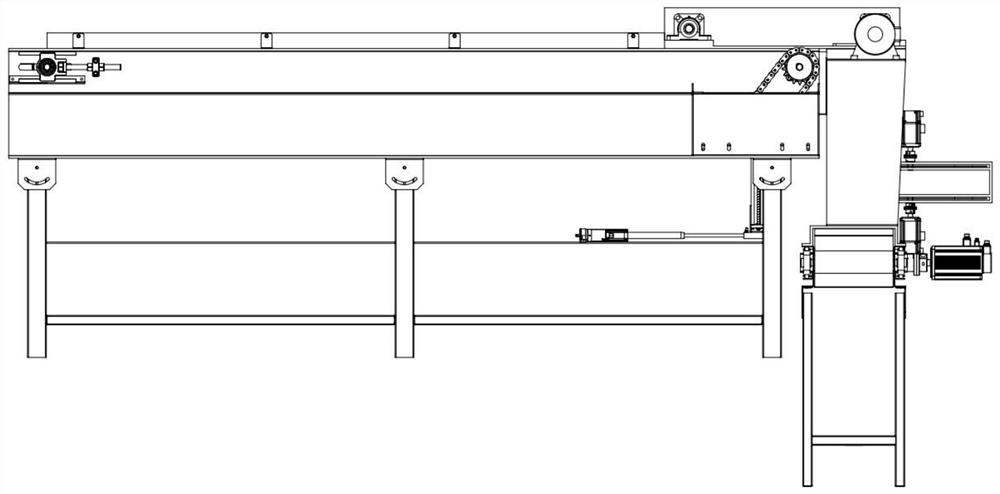

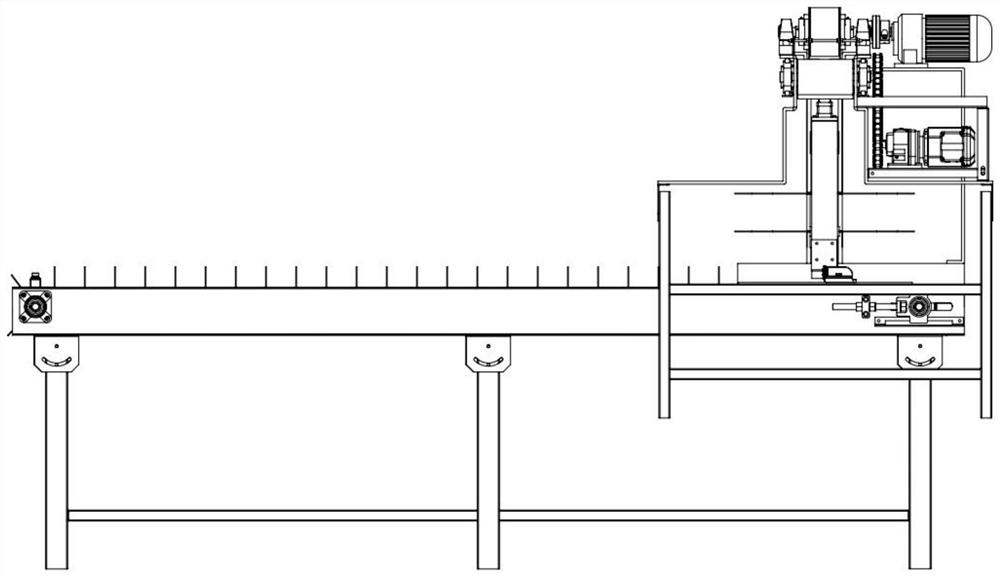

[0051] Embodiment 1: as Figure 1-11 As shown, a drug blister plate stacking device includes a feeding conveying mechanism 1, a non-blocking stacking mechanism 2, a flexible discharging mechanism 3 and a stacking conveying mechanism 4, and the non-clogging stacking mechanism 2 is installed on the feeding conveying mechanism 1 output end, the flexible discharge mechanism 3 is installed on the output end of the non-blocking stacking mechanism 2, and the input end of the stacking conveying mechanism 4 is installed on the output end of the flexible discharge mechanism 3.

[0052] Preferably, the above-mentioned feeding conveying mechanism 1 adopts a belt conveyor, and the belt conveyor is installed on the feeding frame 5, and two symmetrical guide retaining plates 7 are installed above the belt 6 of the belt conveyor, and the two guide retaining plates 7 There are multiple screw rods 8 arranged at intervals for fixed connection, and the two ends of each screw rod 8 are respectivel...

Embodiment 2

[0060] Embodiment 2: A method for using a drug blister plate stacking device, the method comprising the following steps:

[0061] (1) At the initial stage of operation of the stacking production line, the adjustment plate is at the top of the storage bin, and the upper and lower feeding trays are in the state of closing the storage bin. Counting function) to sense whether there is a blister board falling into the storage bin. When the photoelectric eye senses that there is a blister board falling, the signal is transmitted to the PLC controller, and the PLC controller controls the movement of the screw linear module. Make the adjusting plate drop a distance of the thickness of the blister plate, and so on, until the adjusting plate moves to the upper discharge tray;

[0062] (2) When the lead screw linear module no longer descends, the PLC controller controls the action of the electric push rod to move the adjustment plate out of the transverse gap of the storage bin;

[0063...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com