Dust collecting device

A technology of dust collection device and dust collection part, which is applied in cleaning devices, vacuum cleaners, applications, etc., can solve the problems of motor drive noise, high motor drive noise, large motor, etc., to reduce conveying force, reduce conveying resistance, Effect of reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

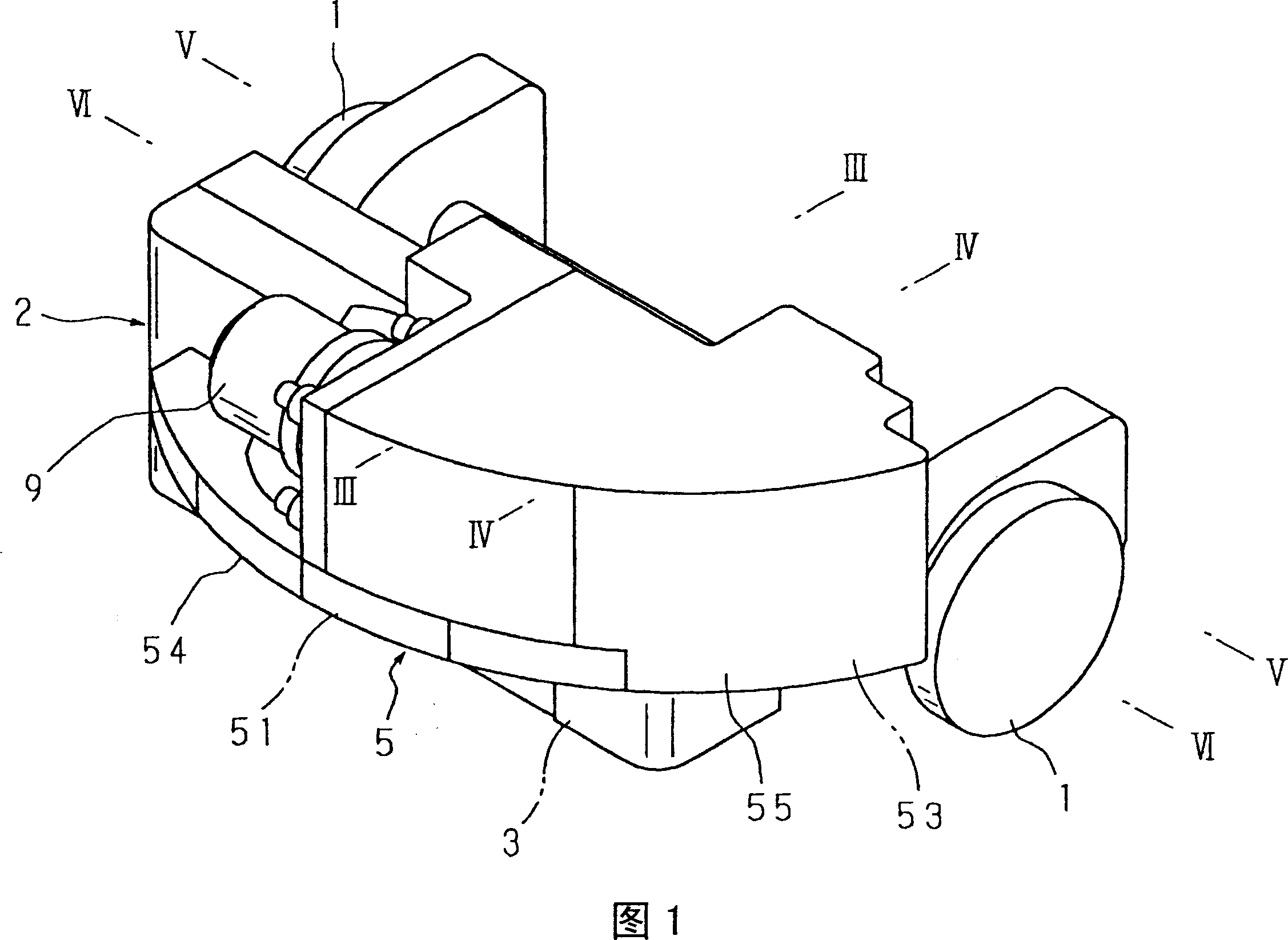

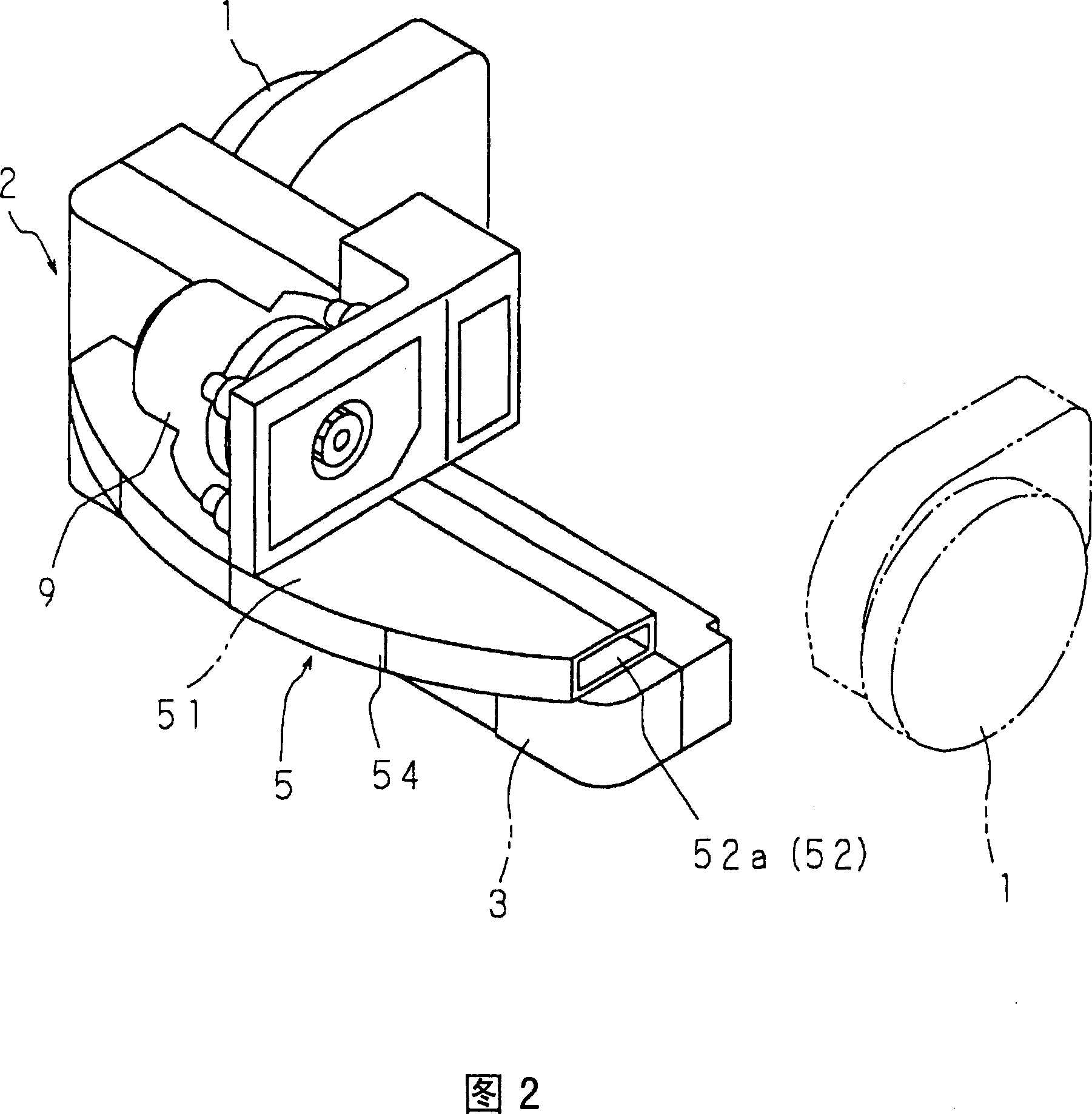

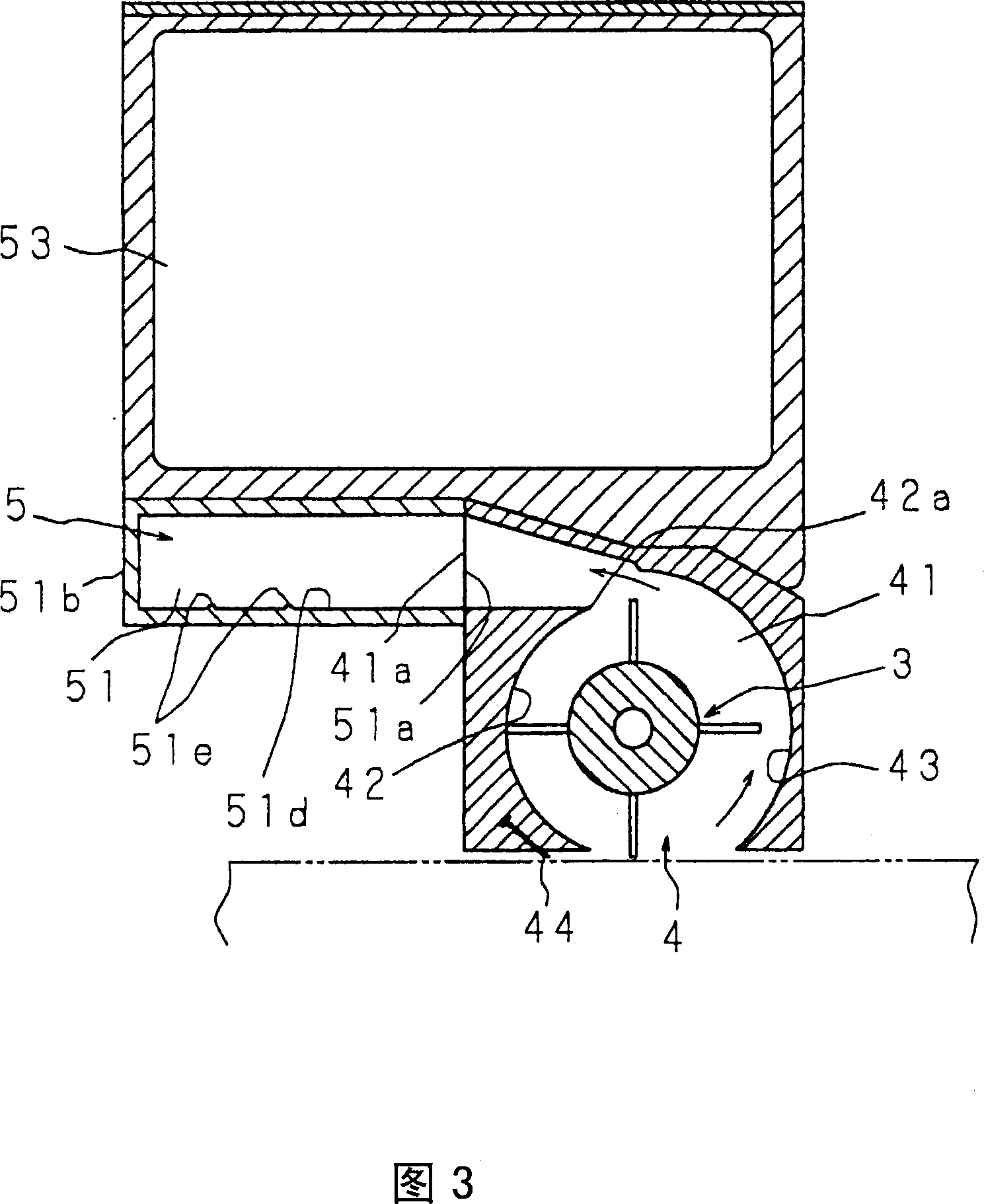

[0122] Fig. 1 is a perspective view showing the configuration of Embodiment 1 of the dust collector of the present invention, Fig. 2 is a perspective view showing a state in which the secondary chamber of the dust collecting unit is removed, and Fig. 3 is an enlarged cross-section taken along line III-III of Fig. 1 Fig. 4 is an enlarged sectional view of the IV-IV line of Fig. 1, Fig. 5 is an enlarged sectional view of the V-V line of Fig. 1, Fig. 6 is an enlarged sectional view of the VI-VI line of Fig. 1, and Fig. 7 shows that after a part is removed Fig. 8 is a plan view showing the structure of the dust collecting part, Fig. 9 is a rear view showing the structure of Embodiment 1, and Fig. 10 is a side view showing the structure of Embodiment 1.

[0123] The dust collecting device shown in Fig. 1 is a self-propelled dust collecting device as a cleaning robot, which includes: a trolley 2 supported by a plurality of traveling wheels 1; The dust part 4; the dust collecting par...

Embodiment approach 2

[0134] 11 is a cross-sectional plan view showing the structure of Embodiment 2 of the dust collector of the present invention, FIG. 12 is a longitudinal sectional side view showing the structure of the main part, FIG. 13 is a cross-sectional plan view showing the structure of the main part, and FIG. 14 It is a longitudinal sectional side view showing the configuration of main parts, FIG. 15 is a plan view with parts omitted, and FIG. 16 is a schematic perspective view of main parts.

[0135] This dust collector has basically the same structure as Embodiment 1. However, as in Embodiment 1, instead of having a communication path 52 on one side in the longitudinal direction of the dust collecting port 51a of the primary chamber 51, it is configured to include a dust collecting The communication path 57 opened on the opposite side of the port 51 a further includes a housing 58 in which the secondary chamber 53 is detachably provided, and the operation body 11 that locks the housing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com