Sub-nozzle for air jet loom

A technology of air injection and auxiliary nozzles, which is applied in looms, textiles, textiles and papermaking, etc., can solve the problems of small weft yarn conveying force, reduced directivity, and high degree of air flow diffusion, so as to improve conveying force, reduce manufacturing costs, The effect of reducing air consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

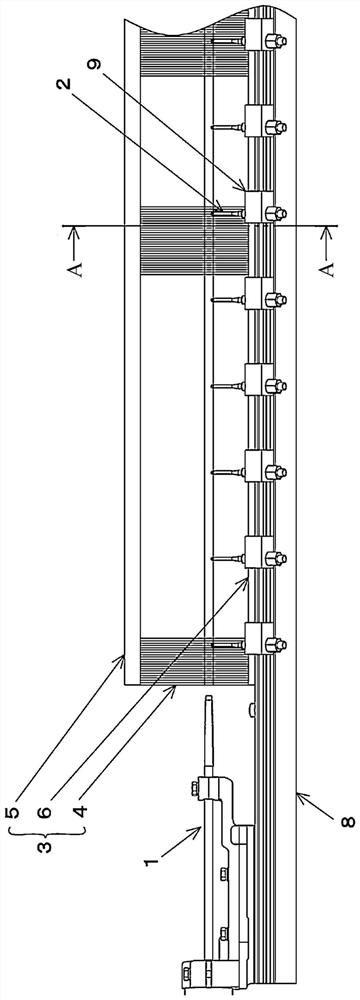

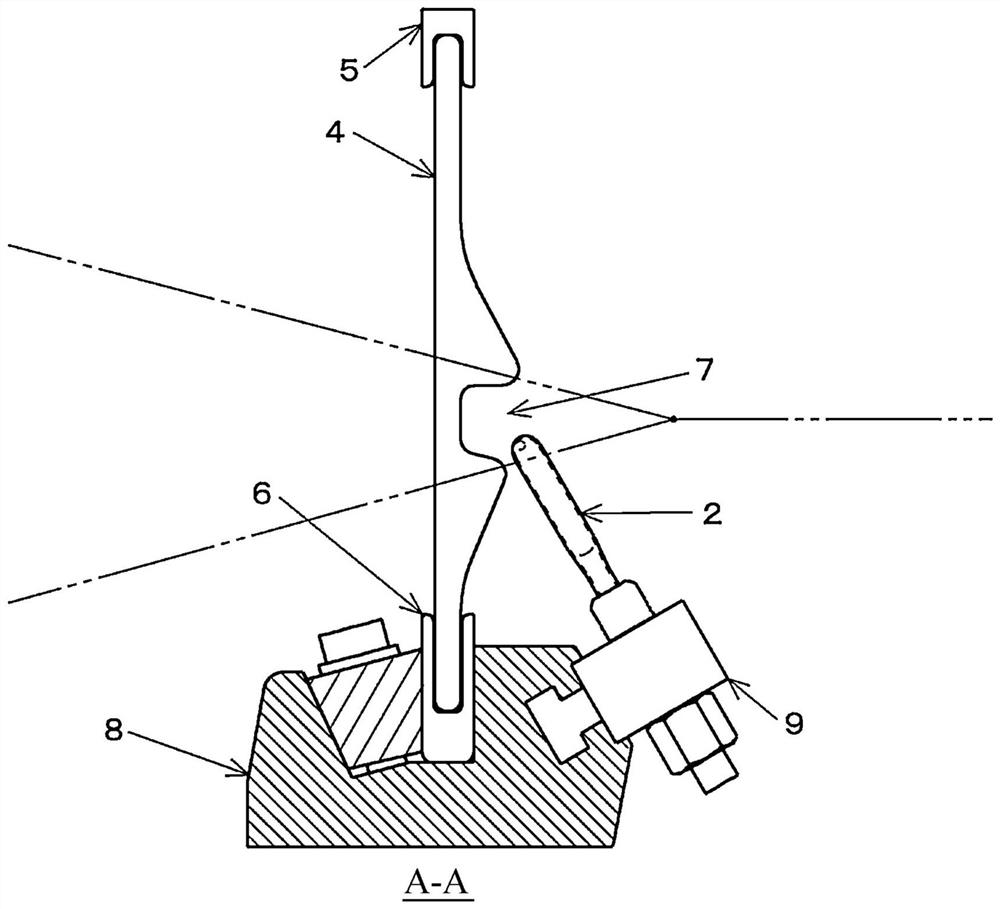

[0040] Such as figure 1 and figure 2 As shown, the air-jet loom to which the sub-nozzle of the present invention is applied includes a main nozzle 1 and a sub-nozzle 2, the main nozzle 1 is used for weft insertion, and a plurality of sub-nozzles 2 are arranged along the shuttle path of the weft yarn. It is used to assist the shuttling of the weft yarn ejected from the main nozzle 1. In addition, this air jet loom includes a reed 3 that beats up the weft yarn that has been picked to a fell of the fabric.

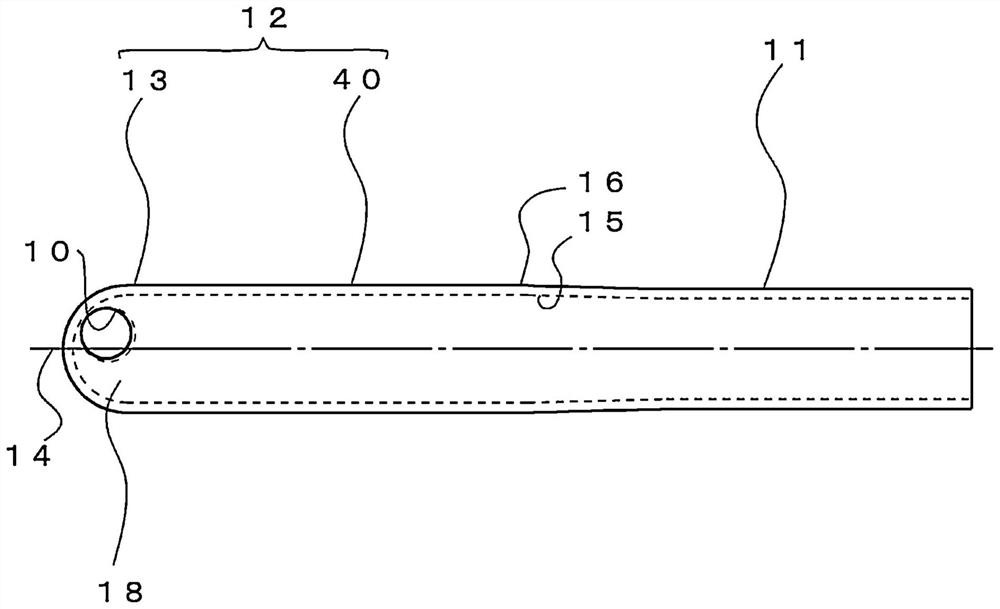

[0041] This reed 3 is a so-called deformed reed, and is configured by providing a plurality of rows of deformed reed teeth 4 having recesses. The deformed reed 3 itself is a well-known structure, so detailed description thereof will be omitted, but each reed tooth 4 has a concave portion formed approximately at the center in the longitudinal direction. Furthermore, each reed tooth 4 is provided in a plurality of rows, and the deformed reed 3 is constituted by being integr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com