Sterilization chemical indicator

A chemical indication and indicator technology, applied in the field of chemical indicators for monitoring the sterilization process, can solve the problems that the color of the indicator changes too fast and cannot be used to monitor the key parameters of the sterilization of the sterilization integrator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

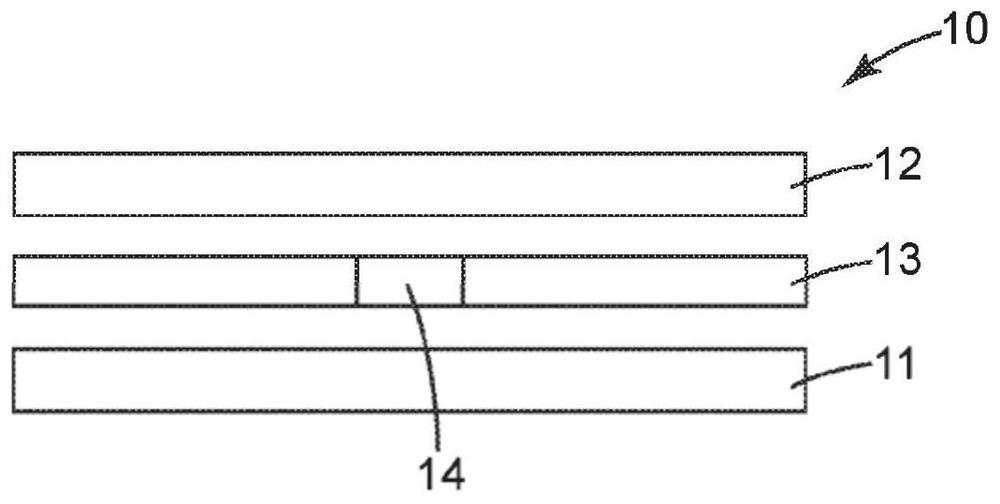

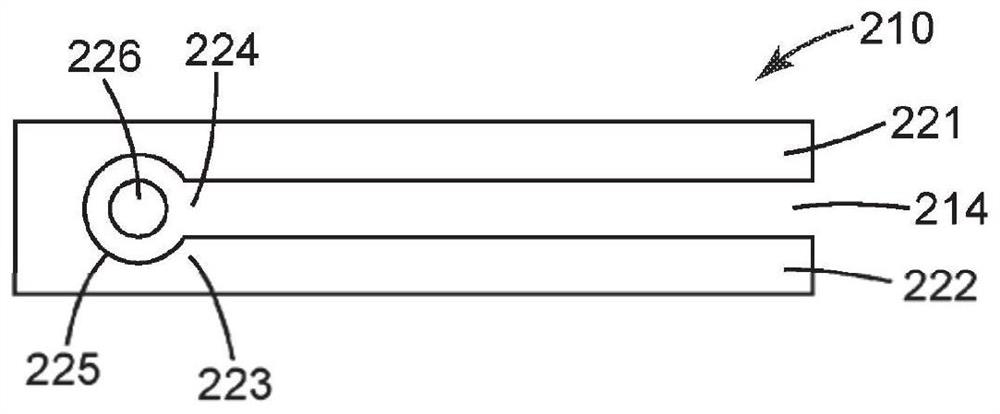

[0247] As mentioned above, use a layer of PET / adhesive structure (3M thickness with 1 mil TM 9996 Transfer tape is laminated on each side of the unprocessed 7 mil PET film) and uses 3M COMPLs as described above. TM The indicator of the chemical indicator composition of the hydrogen peroxide indicator 1248 produces two inch length hydrogen peroxide indicators. The resulting fluid path height is 9 mils. The two ends of the indicator are cut to provide an opening in the two ends to the surrounding environment. Use standard "100S" sterilization cycles and use The 100S sterilizer exposes the indicator to hydrogen peroxide steam. Experimental results Figure 10 Down. The results show that the central area of the indicator changes the color from blue into pink, but does not reach the extent of color change at the two ends of the indicator, and thus shows the successful monitoring process.

Embodiment 2

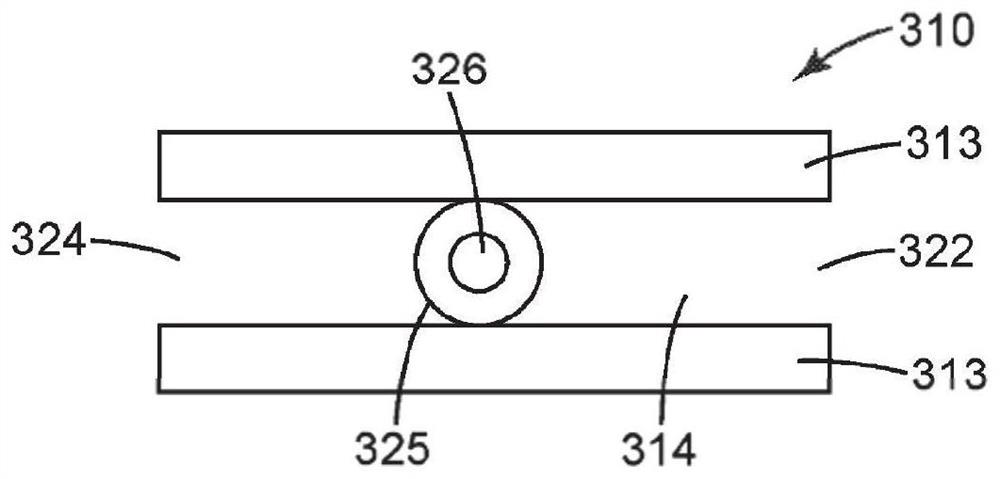

[0249] As mentioned above, use a layer of PET / adhesive structure (3M thickness with 1 mil TM 9996 Transfer tape is laminated on each side of the unprocessed 7 mil PET film) and uses 3M COMPLs as described above. TM The indicator of the chemical indicator composition of the hydrogen peroxide indicator 1248 produces two inch length hydrogen peroxide indicators. The resulting fluid path height is 9 mils. One end of the indicator is cut to provide an opening in one end to the surrounding environment. Use standard "100S" sterilization cycles and use The 100S sterilizer exposes the indicator to hydrogen peroxide steam. Experimental results Figure 11 Down. The result indicates that the area of the opening of the indicator's proximity indicator changes the color from blue to pink, and the area of the closed end of the indicator is kept relatively blue, and the central area of the indicator shows some pink Color, but pink is not as much as the opening of the outline of the indicat...

Embodiment 3

[0251] As mentioned above, use a layer of PET / adhesive structure (3M thickness with 1 mil TM 9996 Transfer tape is laminated on each side of the unprocessed 7 mil PET film) and uses 3M COMPLs as described above. TM The indicator of the chemical indicator composition of the hydrogen peroxide indicator 1248 could prepare a four-inch long hydrogen peroxide indicator. The resulting fluid path height is 9 mils. The two ends of the indicator are cut to provide an opening in the two ends to the surrounding environment. Use standard "100S" sterilization cycles and use The 100S sterilizer exposes the indicator to hydrogen peroxide steam. Experimental results Figure 12Down. The results show that the central area of the indicator has a minimum color change from the blue, wherein the color changes from the two ends of the indicator to pink, thus indicating that the sterilization process is successfully monitored.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com