Equipment and method for producing high curing extruded products

A product with high maturity technology, applied in the field of equipment for the production of puffed products, it can solve the problems of large puffing mechanical energy digestion, low production capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

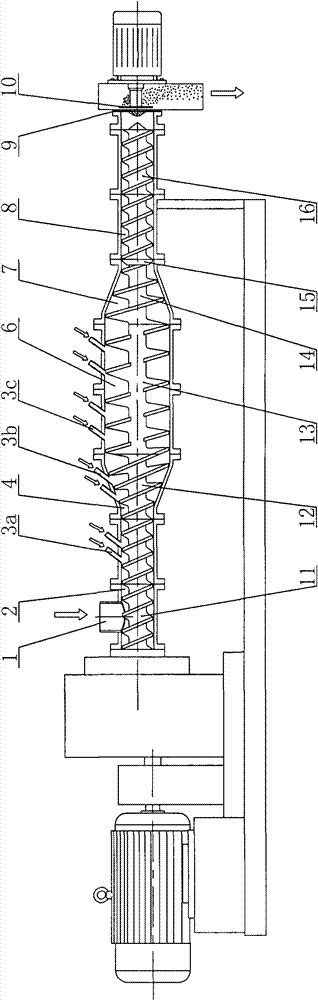

[0025] The mixed material is extruded through the extruding and extruding processing equipment equipped with an enlarged ripening zone.

Embodiment 1

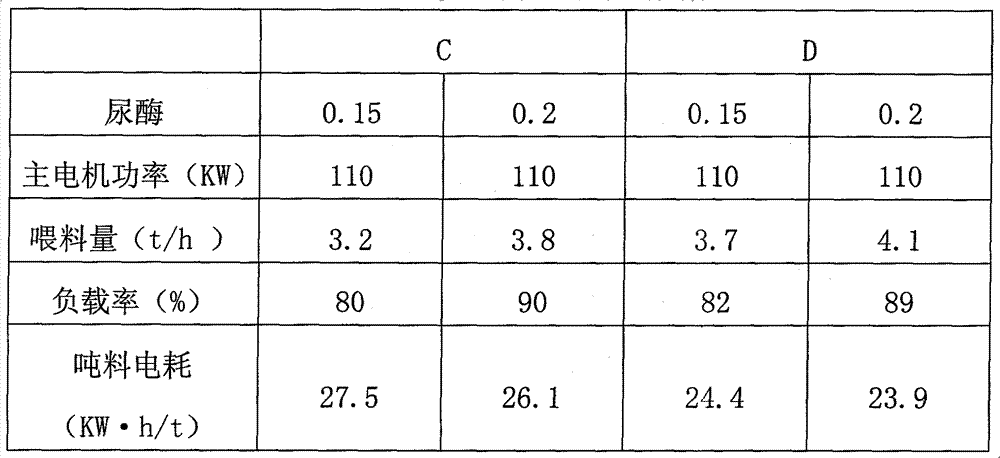

[0026] Embodiment 1 comparative test:

[0027] A) Utilize a single-screw extruder of prior art to carry out production test, obtain relevant parameters. The power of the main motor of the prior art puffing machine is 160 kilowatts, the diameter of the screw is 165 mm, and the length-to-diameter ratio of the screw is 13:1, and the screw configuration area is divided into a feeding area, a kneading area, and a final aging area;

[0028] The formula of the material is shown in Table 1, and the crushing fineness of the material is 95% through the 80 mesh sieve, 99.5% through the 60 mesh sieve, and 100% through the 50 mesh sieve. The material is first pre-cured in a common conditioner. After passing through the conditioner, the gelatinization degree of the material is 45%, the temperature of the material is 95°C, and the moisture content of the material is 19%.

[0029] The formula (weight percentage) of table 1 material

[0030] soybean meal

[0031] The material is ex...

Embodiment 2

[0040] The processing equipment in Example 1 was utilized to expand the soybean material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com