A resistance heater for a single crystal furnace and a method for preparing a silicon single crystal using the resistance heater

A resistance heater, single crystal furnace technology, applied in chemical instruments and methods, single crystal growth, single crystal growth and other directions, can solve the problem of difficult to obtain low oxygen content silicon single crystal, accelerate the melting speed of silicon material, and increase the heat at the bottom of the crucible supply and other problems, to achieve the effect of low oxygen content, reduced transport capacity, and reduced temperature gradient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

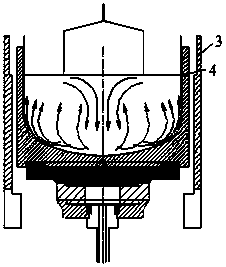

[0030] Using an existing resistance heater (which has a structure such as figure 1 As shown), configure heater A, fill the crucible with 50kg polycrystalline filler, melting power 75kw, seeding power 58kw, crucible rotates clockwise 6rpm, single crystal rotates counterclockwise 12rpm, furnace chamber pressure 20 Torr, pull at 1.2mm / min A silicon single crystal 1 with a diameter of 154-156 mm and a length of 1050 mm was prepared.

[0031] Cut a 2mm sample at the 25mm position of the head of the silicon single crystal a, and measure the oxygen content. The results are shown in Table 2.

Embodiment 2

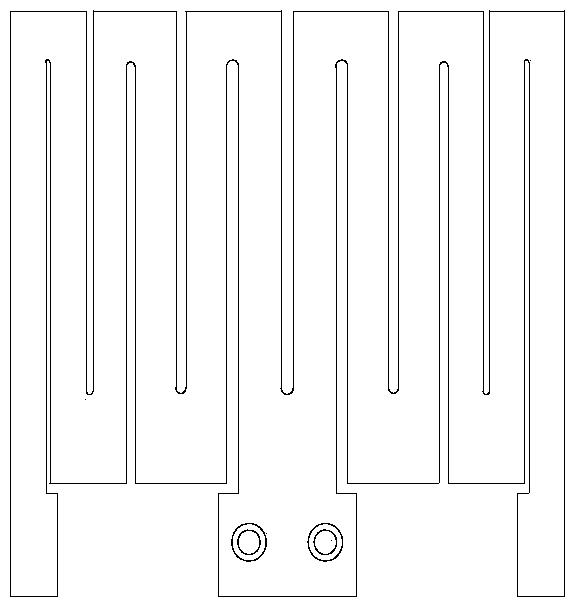

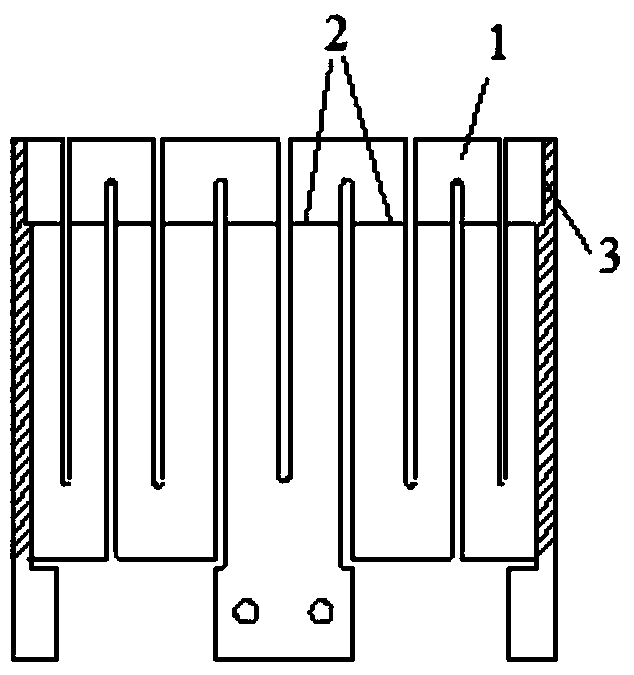

[0033] Use the resistance heater (its structure such as figure 2 As shown), configure heater B, fill the crucible with 50kg polycrystalline filler, melting power 75kw, seeding power 58kw, crucible rotates clockwise 6rpm, single crystal rotates counterclockwise 12rpm, furnace chamber pressure 20 Torr, pull at 1.2mm / min A silicon single crystal b with a diameter of 154-156 mm and a length of 1050 mm was prepared.

[0034] Cut a 2mm sample piece at the 25mm position of the head of the silicon single crystal b, and measure the oxygen content. The results are shown in Table 2.

Embodiment 3

[0036] Use the resistance heater (its structure such as figure 2 As shown), configure heater C, fill the crucible with 50kg polycrystalline filler, melting power 75kw, seeding power 58kw, crucible rotates clockwise 6rpm, single crystal rotates counterclockwise 12rpm, furnace chamber pressure 20 Torr, pull at 1.2mm / min A silicon single crystal c with a diameter of 154-156mm and a length of 1050mm is produced.

[0037] Cut a 2mm sample at the 25mm position of the c head of the silicon single crystal, and measure the oxygen content. The results are shown in Table 2.

[0038] Table 2: Oxygen content in the head of a 16-inch heater growing a 6-inch silicon single crystal

[0039]

[0040]Compared with the thermal system of the existing resistance heater, the thermal system of the resistance heater configured with a 360° annular gap structure can reduce the oxygen content of the silicon single crystal head by more than 10% under the same crystal pulling conditions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com