Rubbish moving device in buried box, negative-pressure rubbish collecting and transporting system and negative-pressure rubbish collecting and transporting method

A mobile device and negative pressure technology, which is applied in the field of buried garbage mobile devices, can solve the problems of increasing the moving distance and increasing the pollution of the surrounding environment, so as to achieve the reduction of the depth of the foundation pit, the thorough collection and transportation of garbage, and the improvement of The effect of delivery efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

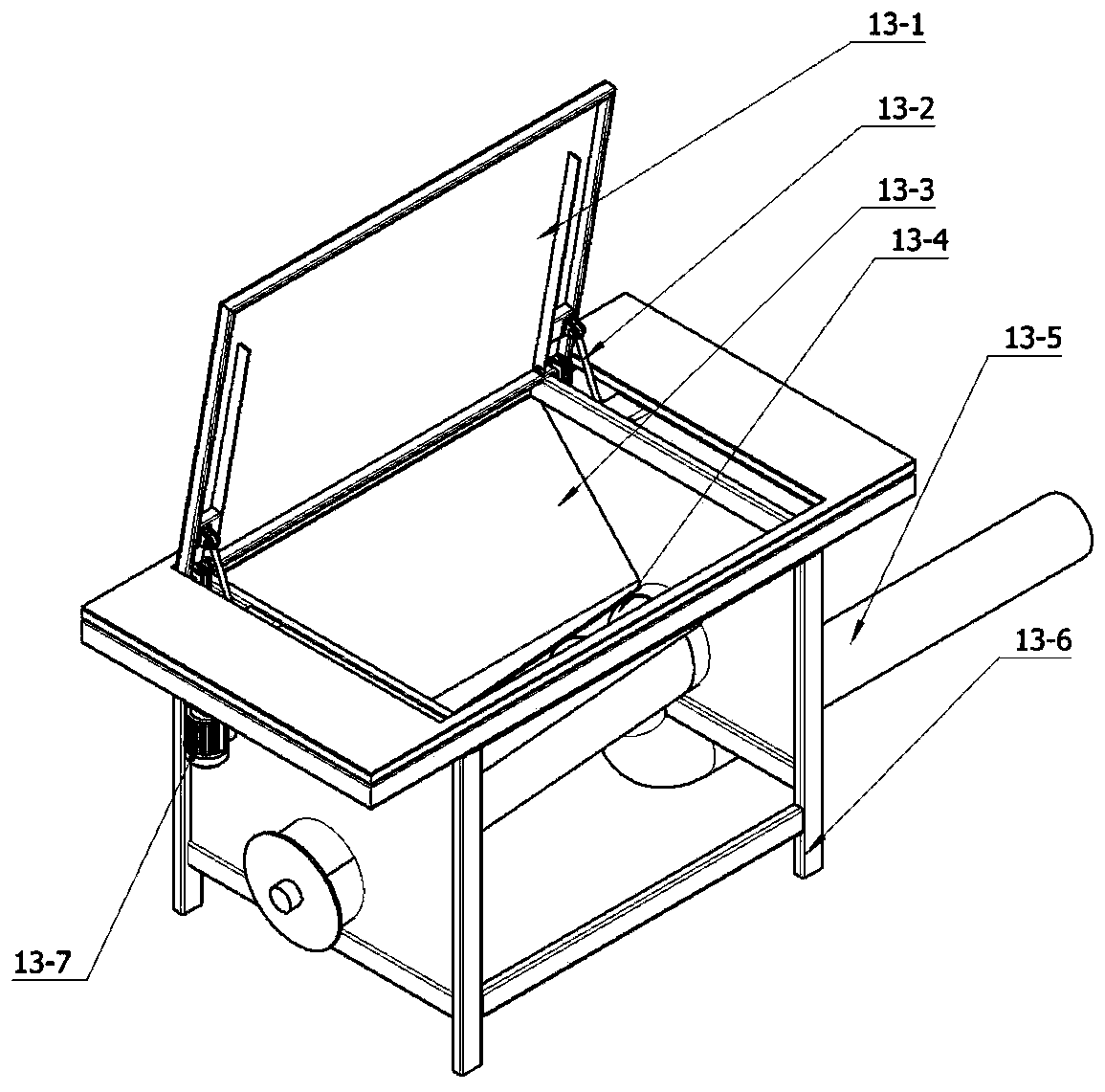

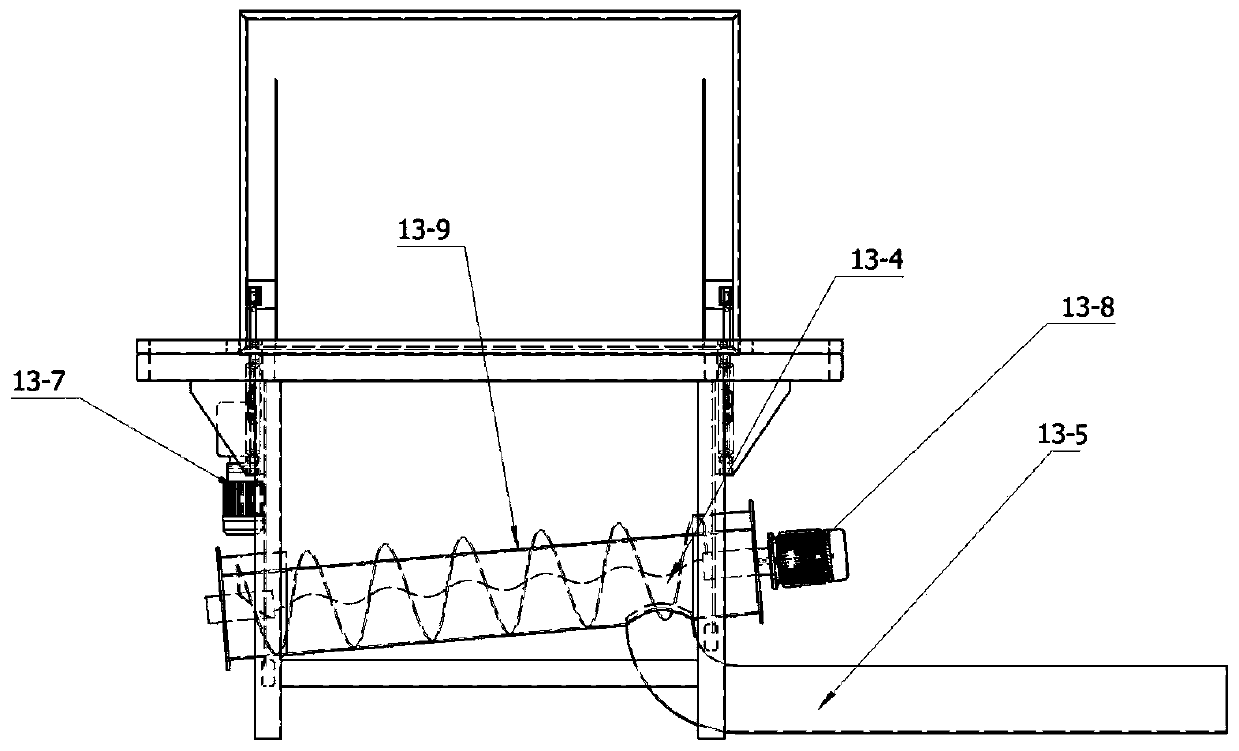

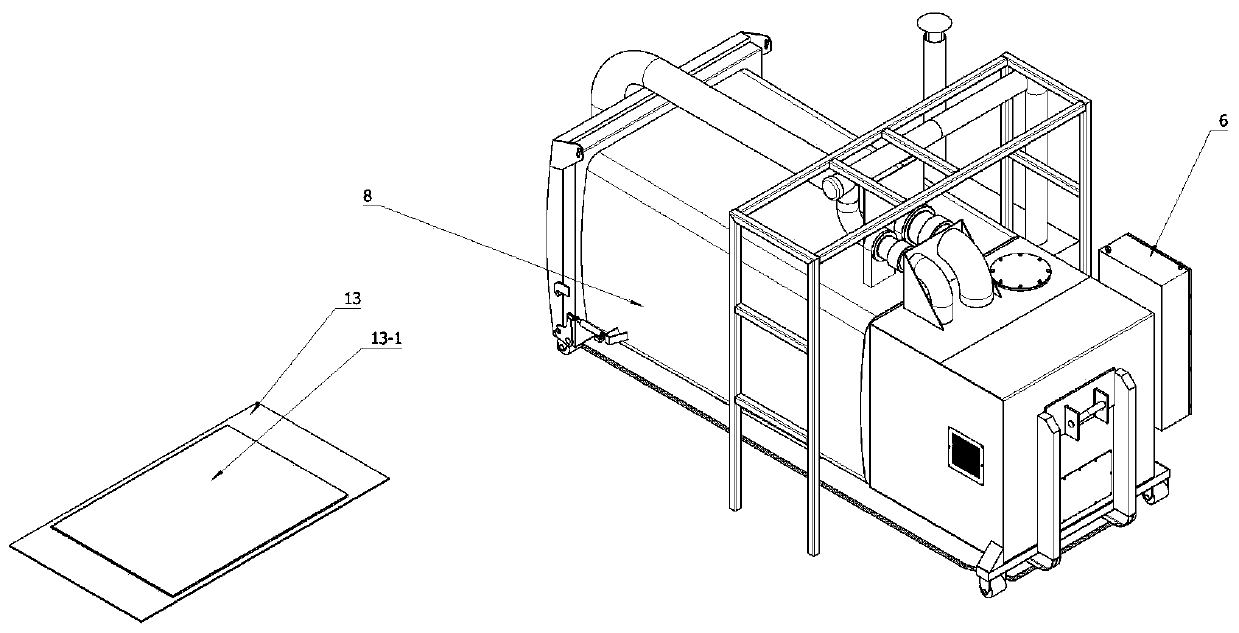

[0037] see figure 1 , figure 2 , the buried garbage moving device in the box, including the foundation pit box, the screw conveyor is arranged in the foundation pit box, the screw conveyor is installed obliquely, the higher end of the screw conveyor is the discharge end, and the screw conveyor The upper part of the casing is axially provided with a bar-shaped feeding port, and the bar-shaped feeding port is set corresponding to the helical blade and the helical groove of the screw conveyor. The upper end of the strip-shaped feeding port is connected to the feeding hopper, and the upper end of the foundation pit box is provided with a feeding door to seal the feeding hopper. The feeding door is opened and closed by the oil cylinder, and the cylinder body of the oil cylinder and the foundation pit box The side wall of the cylinder is hinged, the piston rod of the oil cylinder is hinged with the feeding door, and the driving power of the oil cylinder is provided by the power un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com