External magnetic plate-piston diaphragm type energy-storing closestool flusher

A flusher and diaphragm-type technology, applied in the field of flushing devices, can solve the problems of small potential energy, low water flushing force, fragile ceramic water tank, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

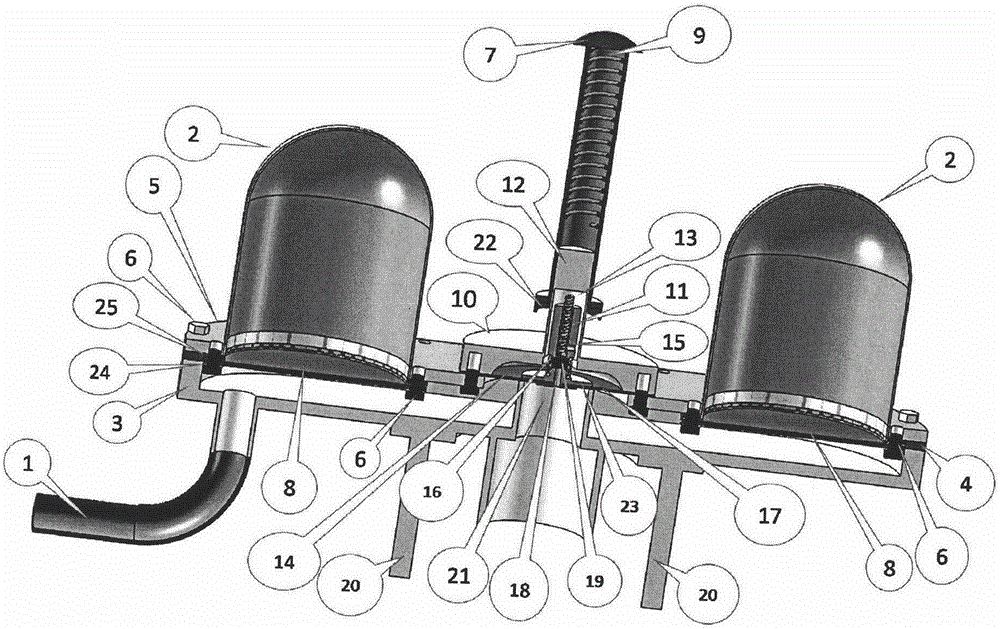

[0016] The present invention is described in further detail below with reference to accompanying drawing:

[0017] Accompanying drawing is a structural sectional view of the present invention.

[0018] The structure of the present invention is as follows:

[0019] Referring to the drawings, the external disk-piston diaphragm energy storage toilet flusher includes: water inlet pipe 1, small water tank 2, base 3, gasket 4, cover plate 5, screw 6, pressure rod 7, diaphragm 8. Pressure rod return spring 9, valve cover 10, cylindrical faucet cover 11, valve cover center column 12, cylindrical faucet cover return spring 13, water sealing piston 14, cylindrical faucet cover pressure guide hole 15, link Spring 16, throttle hole 17, faucet pressure relief hole 18, cylindrical faucet cover sealant block 19, mounting bolt 20, flusher outlet 21, drive disk 22, faucet 23, small water tank pressure ring 24, Small water tank sealing ring 25

[0020] The positional relationship of each com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com