Metallic ionic liquid corrosion inhibitor and preparation method thereof

A metal ion and corrosion inhibitor technology, which is applied in chemical instruments and methods, bulk chemical production, drilling composition, etc. , a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

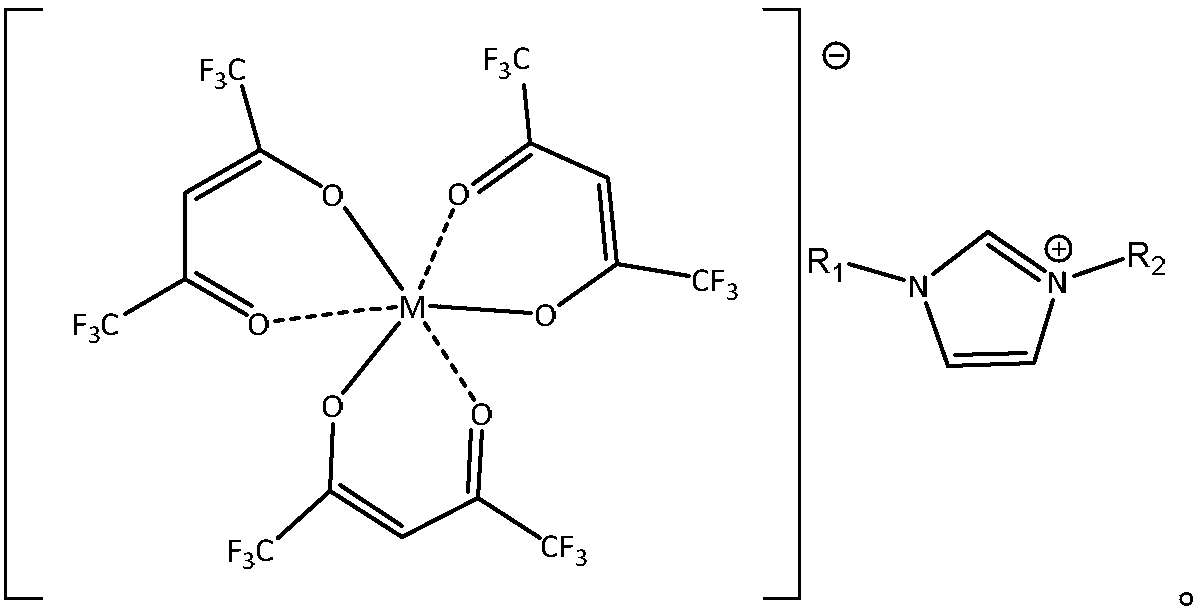

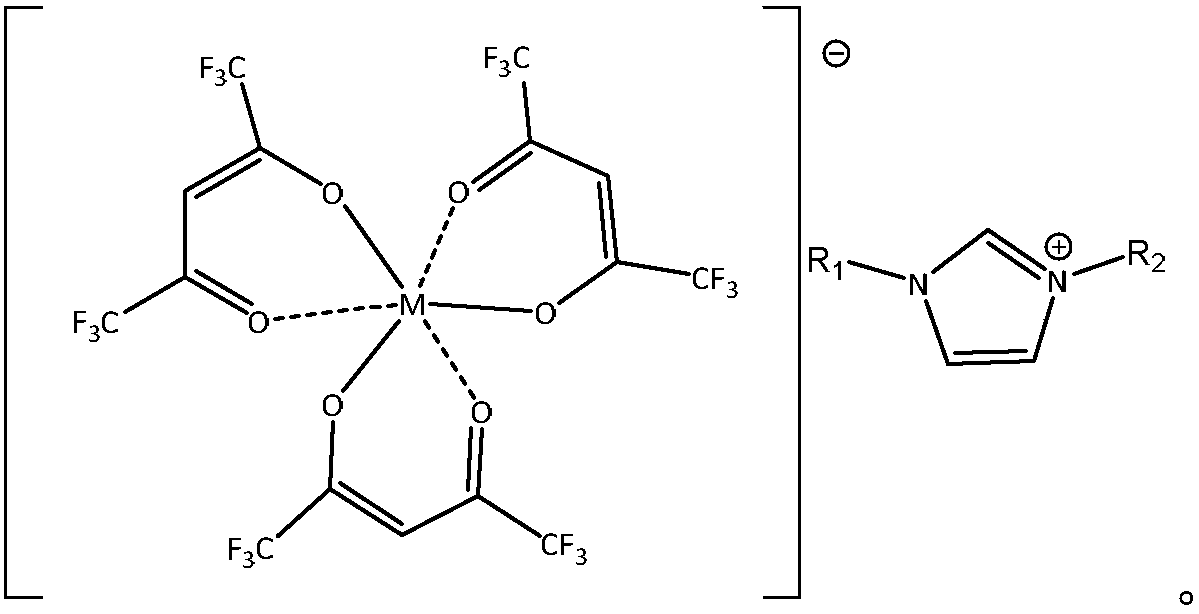

Method used

Image

Examples

Embodiment 1

[0029] Mix 1mmol hexafluoroacetylacetone and 1.5mmol ammonia water in acetonitrile, neutralize and react at 20°C for 10h; add copper chloride for coordination reaction after the reaction; react at 80°C for 8h and add 1-tetradecyl 3- Methylimidazolium chloride, remove the solvent to obtain a crude product; dissolve the obtained crude product in ethyl acetate, then add an equal volume of water, shake for 5 minutes, static layer, separate the liquid to remove the water layer, repeat the above steps 3 times , collecting the ionic liquid-rich phase; removing ethyl acetate by rotary evaporation, and vacuum-drying the obtained product for 24 hours to obtain the metal ionic liquid corrosion inhibitor.

Embodiment 2

[0031] Mix 1mmol hexafluoroacetylacetone and 2mmol ammonia water in acetone, neutralize and react at 40°C for 15h; add ferrous chloride for coordination reaction after the reaction; add 1-hexadecyl 3- Methylimidazolium chloride, remove the solvent to obtain a crude product; dissolve the obtained crude product in ether, then add an equal volume of water, shake for 10 minutes, static layer, separate liquid to remove the water layer, repeat the above steps 5 times, collect The ionic liquid-rich phase; the ether was removed by rotary evaporation, and the obtained product was vacuum-dried for 22 hours to obtain the metal ionic liquid corrosion inhibitor.

Embodiment 3

[0033] Mix 1mmol hexafluoroacetylacetone and 1.7mmol ammonia water in acetone, neutralize at 30°C for 20h: after the reaction, add manganese chloride for coordination reaction; react at 70°C for 36h, add 1-dodecyl 3- Methylimidazolium chloride, remove the solvent to obtain a crude product; dissolve the obtained crude product in ethyl acetate, then add an equal volume of water, shake for 3 minutes, static layer, separate the liquid to remove the water layer, repeat the above steps 4 times , collecting the ionic liquid-rich phase; removing ethyl acetate by rotary evaporation, and vacuum-drying the obtained product for 20 hours to obtain the metal ionic liquid corrosion inhibitor.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com