Automatic oil injection system for head sheave of multi-rope friction-type elevator

An automatic oiling and friction technology, applied in the direction of mechanical equipment, engine components, engine lubrication, etc., can solve the problems of safety production and personal health hazards, difficult to accurately grasp the timeliness of oiling, unfavorable physical and mental health of operators, etc., to improve Scientific and technological support capabilities, protection of physical and mental health, and the effect of quantitative and precise oil injection and lubrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

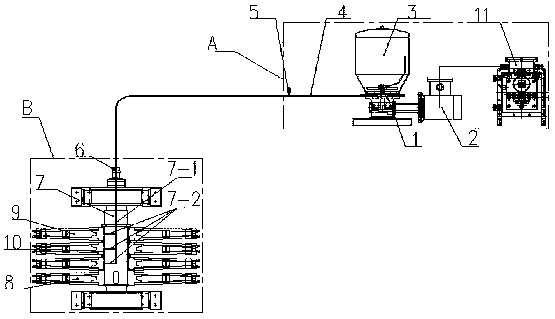

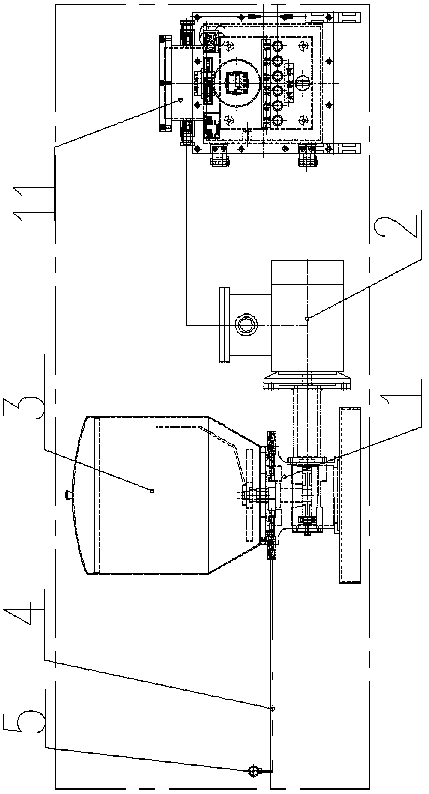

[0027] The following is a specific embodiment of the present invention, and the present invention will be further described in conjunction with the accompanying drawings.

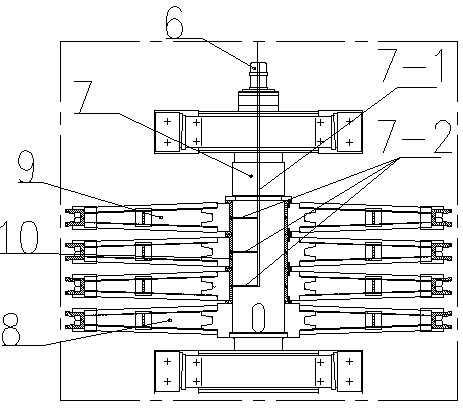

[0028] Such as Figure 1 to Figure 4 As shown, a multi-rope friction hoist top wheel automatic oiling system, a fixed wheel 8 is fixedly installed on the top wheel main shaft 7, and the fixed wheel 8 and the top wheel main shaft 7 are connected by a flat key. One side of the fixed wheel 8 is provided with three traveling wheels 9, and the traveling wheels 9 are installed on the main shaft 7 of the sky wheel through the bearing bush 10; The sliding wear of the speed difference on the rope groove of the sky wheel; the bearing bush 10 can make the flexible rotation between the traveling wheel and the main shaft of the sky wheel.

[0029] There is a main oil passage 7-1 at one end axis position of the sky wheel main shaft 7, and an oil distribution passage 7-2 connected with the main oil passage 7-1 is opened ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com