Hydrogenation method for producing good quality catalytic cracking material

A kind of catalytic cracking raw material, high-quality technology, used in refining to remove heteroatoms, petroleum industry, refining hydrocarbon oil, etc., can solve the problems of high reaction pressure and high relative cost, achieve low operating pressure, reduce processing costs, and delay pressure drop. rising effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

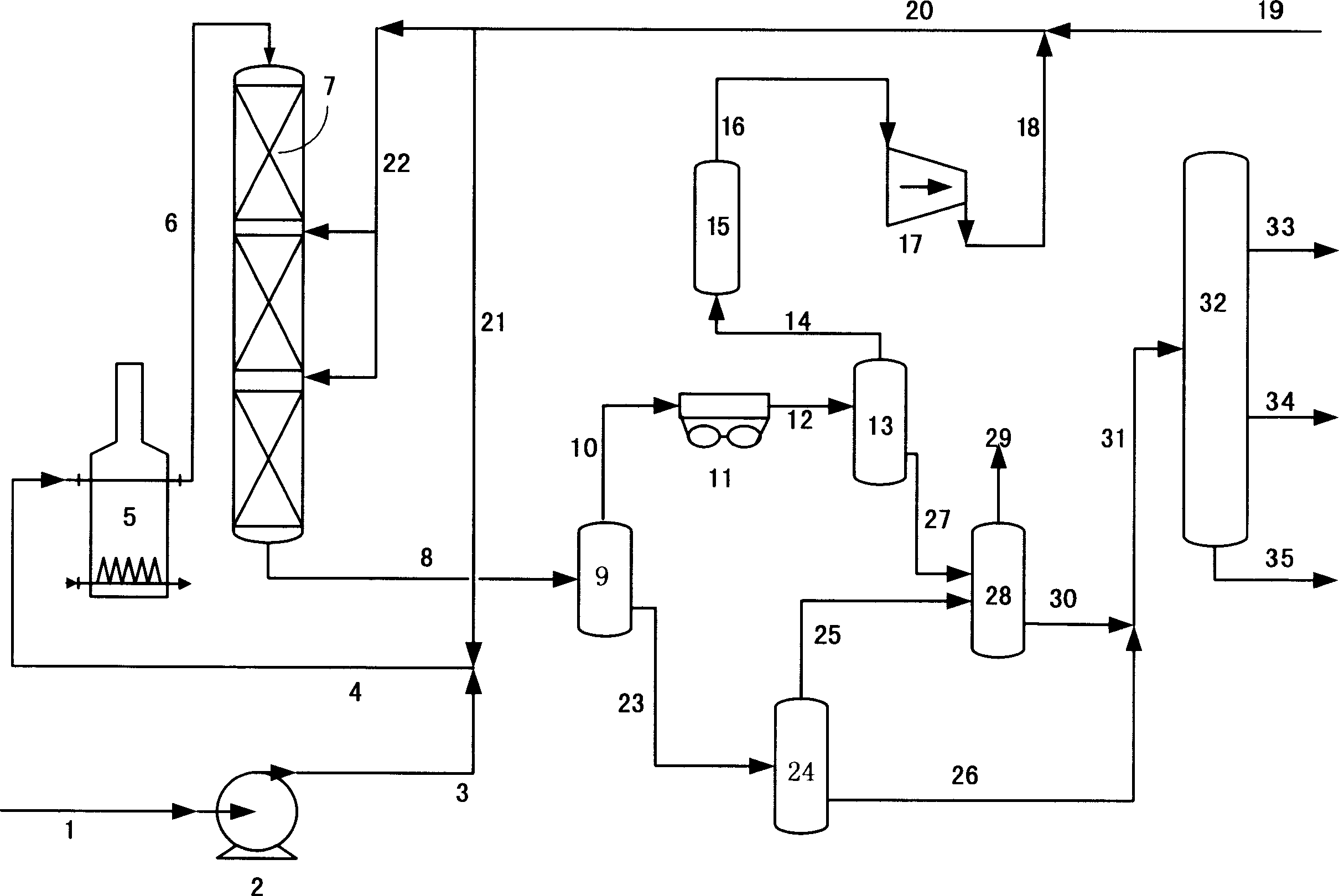

Image

Examples

Embodiment 1

[0024] A kind of VGO is used as raw material oil A, and the properties of raw material oil are shown in Table 1. From Table 1, it can be seen that the sulfur content of raw material oil A is as high as 27000 μg / g. The raw material A enters the hydrogenation reactor together with the hydrogen, and successively contacts and reacts with the hydrogenation protection agent and the hydrogenation catalyst. The effluent after the reaction is cooled and separated, the hydrogen-rich gas is recycled, and the liquid product enters the fractionation system to be separated into naphtha Distillate, Diesel Distillate and Refined Gas Oil Distillate. Based on the overall catalyst volume, the loading volume percentages of the hydrogenation protecting agent and the hydrotreating catalyst are respectively 9% and 91%, wherein the hydrogenation protecting agent includes the hydrogenation protecting agent I and the hydrogenation protecting agent II, both of which are loaded The volume ratio is 1:1. ...

Embodiment 2

[0026] A mixed oil of DAO, CGO and VGO (mass ratio 36:5:59) is used as raw material B, and its properties are shown in Table 1. It can be seen from Table 1 that the metal content of raw material B is 3.0 μg / g. The raw material oil A enters the hydrogenation reactor together with the hydrogen, and reacts with the hydrogenation protection agent, the hydrodemetallization catalyst and the hydrogenation treatment catalyst in sequence. The effluent after the reaction is cooled and separated, the hydrogen-rich gas is recycled, and the liquid product enters the The fractionation system separates into naphtha fraction, diesel fraction and refined gas oil fraction. Based on the overall catalyst volume, wherein the loading volume percentages of hydroprotecting agent, hydrodemetallization catalyst and hydrotreating catalyst are respectively 12%, 23% and 65%; wherein the hydroprotecting agent comprises hydroprotecting agent 1 and As for the hydrogenation protecting agent II, the filling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com