A kind of desulfurization method of ferromanganese ore

A technology of ferromanganese ore and slag powder, which is applied in the desulfurization field of ferromanganese ore, which can solve the problems of difficulty in desulfurization of ferromanganese ore, high cost, and large heat consumption, and achieve good desulfurization effect and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

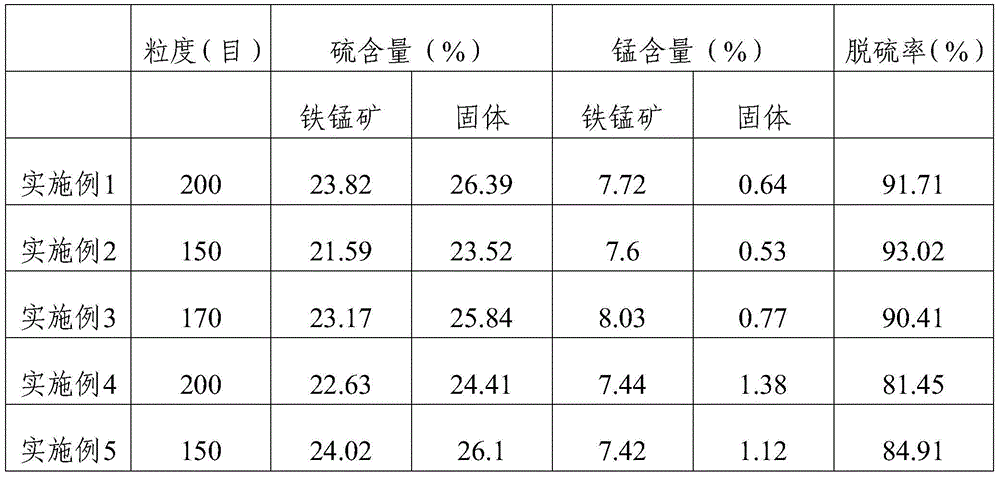

Examples

Embodiment 1

[0022] A method for desulfurizing ferromanganese ore, comprising the following steps:

[0023] (1) Ferromanganese ore is crushed to a particle size of 200 mesh, and sieved to obtain ore powder;

[0024] (2) At 90°C, add water to the mineral powder and stir evenly to obtain a slurry;

[0025] (3) Stir the slurry, and charge sulfur dioxide gas at the same time, after stirring for 35 minutes, after standing for 15 minutes, add the auxiliary agent and stir for 30 seconds, wherein the amount of the auxiliary agent added is 1 / 28 of the volume of the slurry to obtain the intermediate material;

[0026] (4) Add cellulose to the intermediate material, stir for 30 minutes, and separate to obtain floc, solid and sulfate solution.

[0027] The amount of water added in the step (2) is 2.5 times of the mineral powder weight.

[0028] Stirring speed is 120r / min in the described step (3).

[0029] Add sulfur dioxide gas in the described step (3), and its add-on is 1 / 10 of slurry volume.

...

Embodiment 2

[0034] A method for desulfurizing ferromanganese ore, comprising the following steps:

[0035] (1) Ferromanganese ore is crushed to a particle size of 150 mesh, and sieved to obtain ore powder;

[0036] (2) At 85°C, add water to the mineral powder and stir evenly to obtain a slurry;

[0037] (3) Stir the slurry, and charge sulfur dioxide gas at the same time, after stirring for 32 minutes, after standing for 15 minutes, add the auxiliary agent and stir for 30 seconds, wherein the amount of the auxiliary agent added is 1 / 25 of the volume of the slurry to obtain the intermediate material;

[0038] (4) Add cellulose to the intermediate material, stir for 30 minutes, and separate to obtain floc, solid and sulfate solution.

[0039] The amount of water added in the step (2) is 2 times of the mineral powder weight.

[0040] In the step (3), the stirring speed is 100r / min.

[0041] Add sulfur dioxide gas in the described step (3), and its add-on is 1 / 12 of slurry volume.

[0042]...

Embodiment 3

[0046] A method for desulfurizing ferromanganese ore, comprising the following steps:

[0047] (1) Ferromanganese ore is crushed to a particle size of 170 mesh, and sieved to obtain ore powder;

[0048] (2) At 96°C, add water to the mineral powder and stir evenly to obtain a slurry;

[0049] (3) Stir the slurry while filling it with sulfur dioxide gas. After stirring for 34 minutes, after standing for 12 minutes, add the auxiliary agent and stir for 30 seconds, wherein the amount of the auxiliary agent added is 1 / 28 of the volume of the slurry to obtain the intermediate material;

[0050] (4) Add cellulose to the intermediate material, stir for 30 minutes, and separate to obtain floc, solid and sulfate solution.

[0051] The amount of water added in the step (2) is 2.5 times of the mineral powder weight.

[0052] Stirring speed is 120r / min in the described step (3).

[0053] Add sulfur dioxide gas in the described step (3), and its add-on is 1 / 10 of slurry volume.

[0054]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com