A hydrogenation method for treating high-nitrogen and high-aromatic low-quality diesel feedstock

A low-quality diesel oil and high aromatics technology, applied in the field of hydrocarbon oil cracking, can solve the problem of low conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

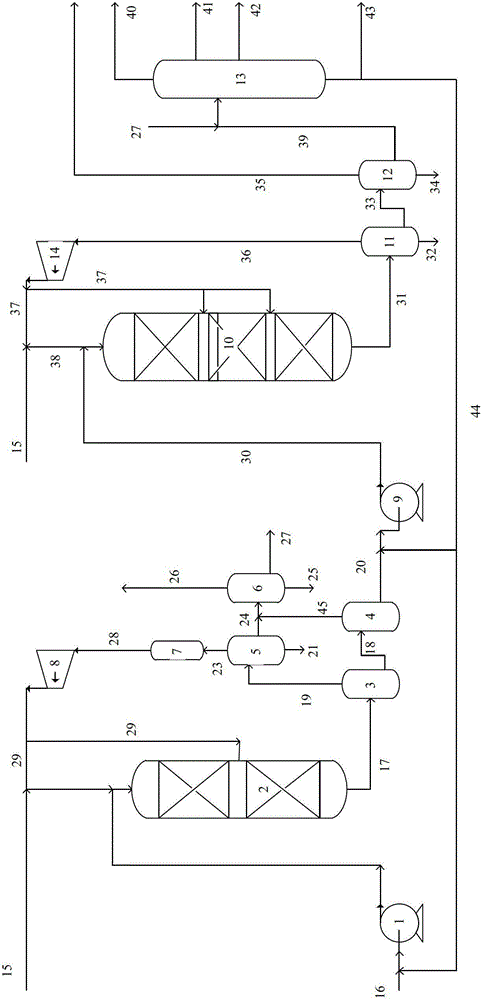

Method used

Image

Examples

preparation example Construction

[0048] The preparation process and composition of the first hydrotreating catalyst B are as follows:

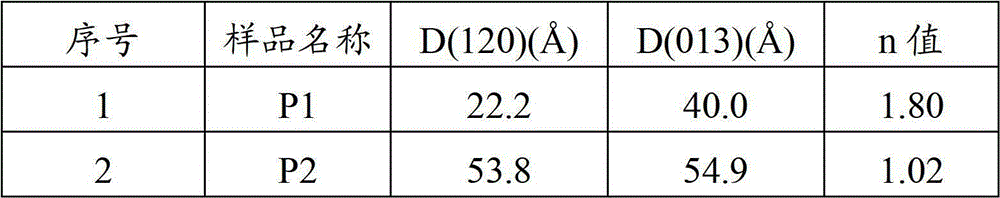

[0049] The n values of all pseudo-boehmite in the examples of the present invention are determined by XRD method. The XRD test was carried out on a SIMENSD5005 X-ray diffractometer, with CuKα radiation, 44 kV, 40 mA, and a scanning speed of 2° / min. According to the Scherrer formula: D=Kλ / (Bcosθ) (D is the grain size, λ is the diffraction wavelength of the target material, B is the half-maximum width of the corrected diffraction peak, and 2θ is the position of the diffraction peak), respectively by 2θ Calculate the grain size of (120) as D(120) for the parameter of 23-33 ° peak, calculate the grain size of (031) as D (031) with the parameter of 34-43 ° peak with 2θ, and press The formula n=D(031) / D(120) calculates the value of n.

[0050] The preparation method of pseudo-boehmite P1 with 1.1≤n≤2.5 used in the examples of the present invention is as follows:

[0051] In a ...

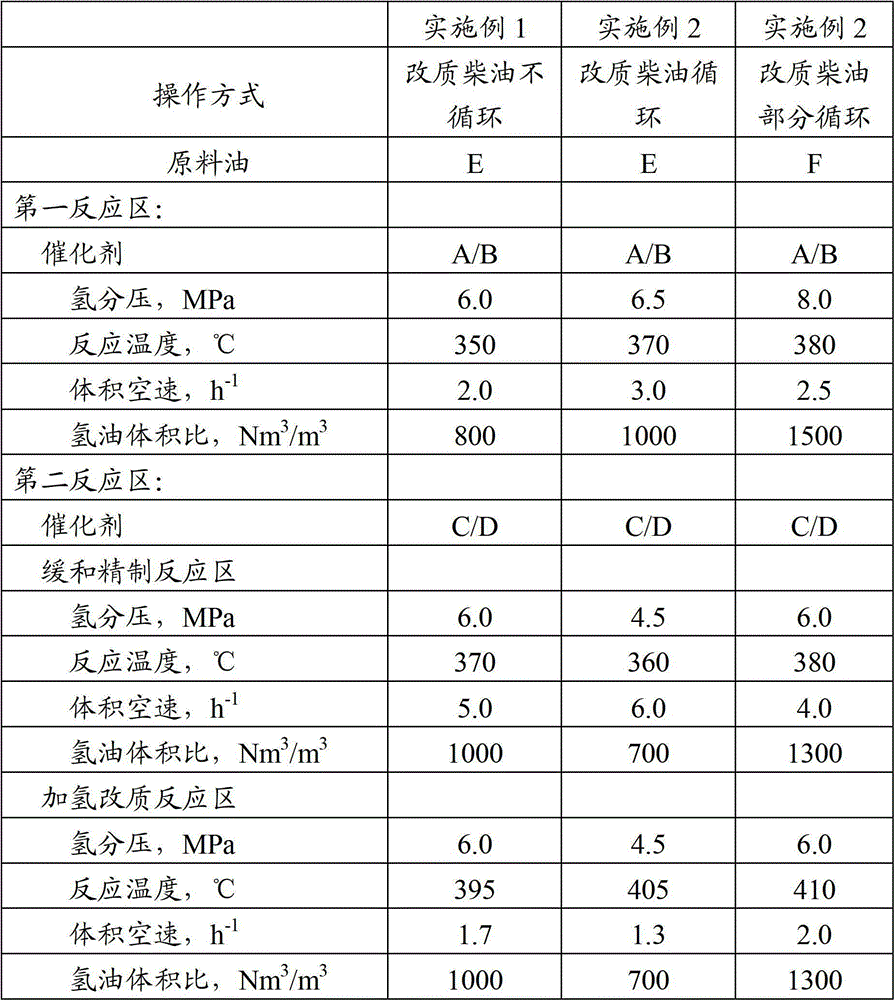

Embodiment 1

[0059] The raw material oil E enters the first reaction zone together with hydrogen, contacts and reacts with the protective agent A and the first hydrotreating catalyst B, and the reaction effluent in the first reaction zone enters the hot high-pressure separator, cold high-pressure separator, and hot low-pressure separator , cold low-pressure separator, etc. after separation, the obtained gas phase stream removes H 2 S and NH 3 Finally, it is recycled as a hydrogen-rich gas, and the separated light hydrocarbons enter the fractionation tower, and the separated hydrogenated stream has a total aromatic content of 79 mass%, wherein the single-ring aromatic content is 55 mass%, and the organic nitrogen content is 100 μg / g.

[0060] The hydrogenated stream enters the second reaction zone, and successively contacts and reacts with the second hydrofinishing catalyst C and the hydrogenation upgrading catalyst D, and the reaction effluent in the second reaction zone is cooled, separat...

Embodiment 2

[0064] The raw material oil E enters the first reaction zone together with hydrogen, contacts and reacts with the protective agent A and the first hydrotreating catalyst B, and the reaction effluent in the first reaction zone enters the hot high-pressure separator, cold high-pressure separator, and hot low-pressure separator , cold low-pressure separator, etc. after separation, the obtained gas phase stream removes H 2 S and NH 3 Finally, it is recycled as a hydrogen-rich gas, and the separated light hydrocarbons enter the fractionation tower, and the separated hydrogenated stream has a total aromatic content of 82% by mass, of which the single-ring aromatic content is 59% by mass, and the organic nitrogen content is 130 μg / g.

[0065] The hydrogenation stream enters the second reaction zone, and successively contacts and reacts with the second hydrofinishing catalyst C and the hydrogenation upgrading catalyst D, and the reaction effluent in the second reaction zone is cooled,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com