A method for processing heavy oil with combined process

A combined process and heavy oil technology, applied in the direction of only multi-stage series refining and cracking process, can solve the problems of light oil yield decrease, gas yield increase, hydrogenated heavy oil specific gravity, etc., to improve utilization rate , Eliminate mutual influence and save oil resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

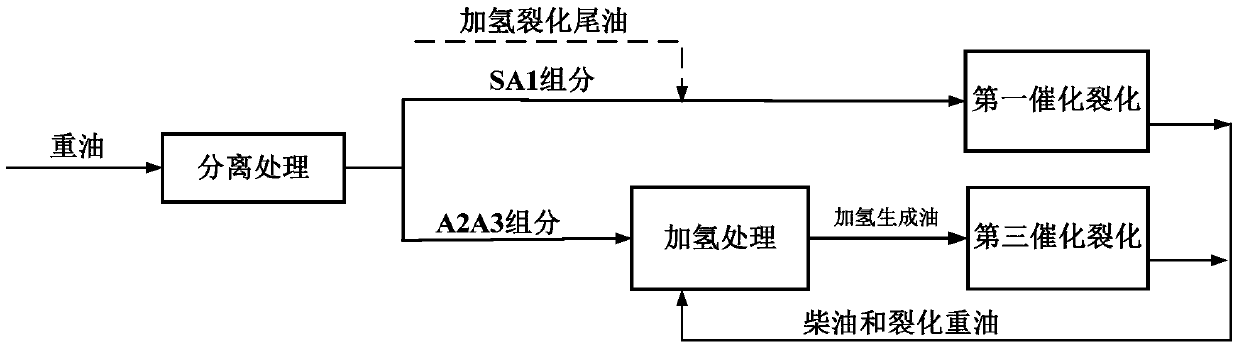

[0061] The second specific embodiment of the present invention is as figure 2 Shown:

[0062] After the heavy oil is separated and treated, the SA1 component and the A2A3 component are obtained, and the obtained SA1 component is subjected to the first catalytic cracking reaction to obtain dry gas, liquefied gas, gasoline, diesel oil, coke and cracked heavy oil; the obtained A2A3 component The hydroprocessing reaction is carried out, and the obtained hydrogenated oil is subjected to the third catalytic cracking reaction to obtain dry gas, liquefied gas, gasoline, diesel oil, coke and cracked heavy oil; the obtained diesel oil and cracked heavy oil are subjected to hydroprocessing reaction to obtain hydrogenated Hydrogen produces oil. At the same time, the hydrocracking tail oil and the SA1 component can be mixed together to perform the first catalytic cracking reaction.

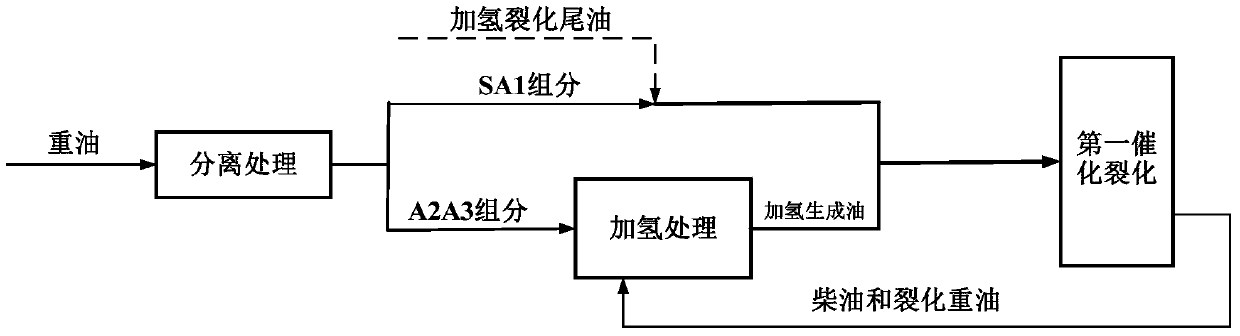

[0063] The third specific embodiment of the present invention is as image 3 Shown: SA1 component and A...

Embodiment 1

[0071] This example is used to illustrate the implementation method of the heavy oil separation unit in the method for processing heavy oil with the combined process provided by the present invention. Fill the bottom of the separation column with 30g of neutral alumina (the specific surface area is 152m 2 / gram, pore volume is 0.213 milliliters / gram), the aluminum oxide (massfraction of silver is 7.05 mass %, adopts silver nitrate impregnation method to prepare) of 110g load silver ions in the middle of filling, upper layer fills 30g silica gel (specific surface area is 479 meters 2 / gram, the pore volume is 0.349 milliliters / gram); The lower end of the separation column is connected with the vacuum system. The total volume of the stationary phase was 150 mL. Take vacuum gas oil (VGO, Tahe crude oil is taken from the Tahe Oilfield of Sinopec Northwest Branch Company, and obtain Tahe vacuum gas oil through true boiling point distillation at the Research Institute of Petrochemi...

Embodiment 2

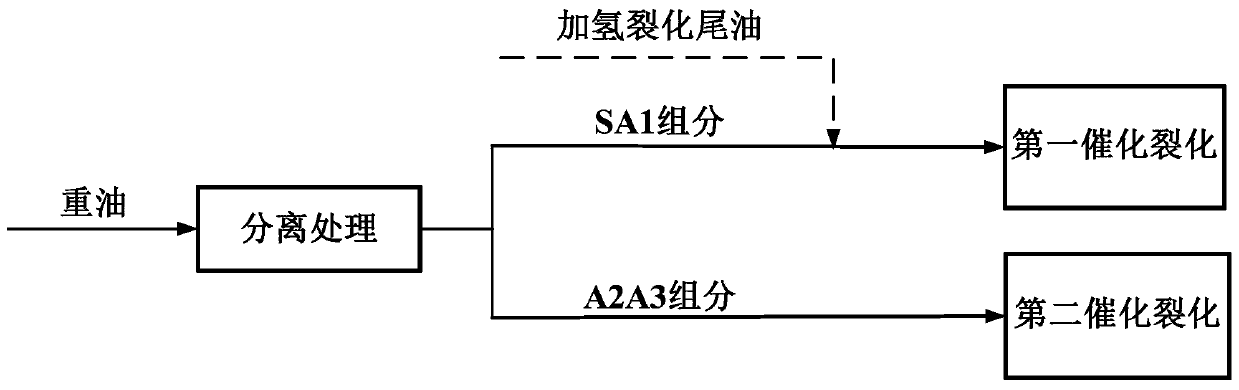

[0073] Such as figure 1 As shown, the SA1 component and the A2A3 component obtained in Example 1 are respectively used as catalytic cracking raw materials, and the reaction temperature is 500 ° C, the agent-oil mass ratio is 4, and the space velocity is 16 hours -1 The first catalytic cracking reaction and the second catalytic cracking reaction are carried out under certain conditions, the conversion rate, total liquid yield, light oil yield, and six main products dry gas, liquefied gas, gasoline, diesel oil, cracked heavy oil and coke The yield, sulfur content and nitrogen content in gasoline are shown in Table 4.

[0074]From the data in Table 4, it can be seen that compared with the experimental results of VGO direct catalytic cracking, after summarizing the liquefied petroleum gas and gasoline obtained by catalytic cracking of S and A2A3 components respectively, the yields of liquefied petroleum gas and gasoline are respectively higher than 1 The liquefied gas and gasolin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com