Corn ear chopping and kernel crushing device as well as working method and application thereof

A crushing device and the technology of corn ears, which are applied in the field of agricultural machinery, can solve the problems that need to be improved, and achieve the effects of improving crushing quality, convenient operation, and improving the quality of crushing ears

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

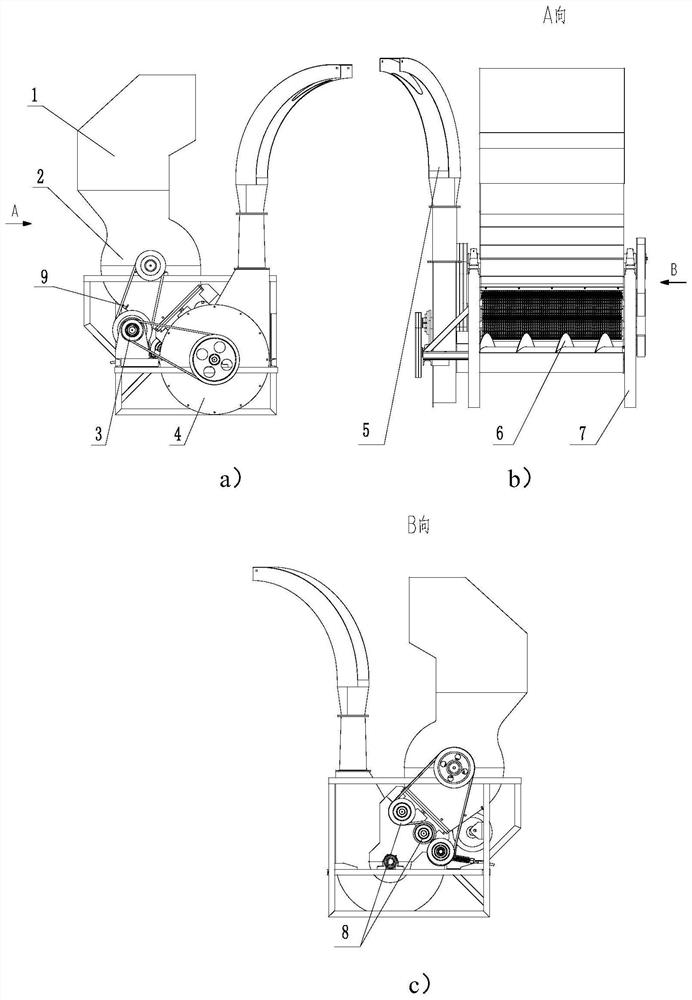

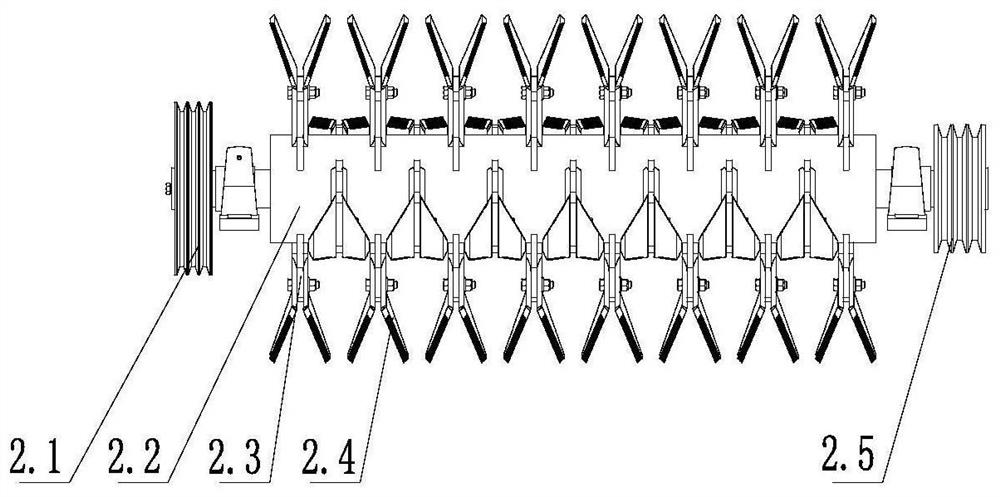

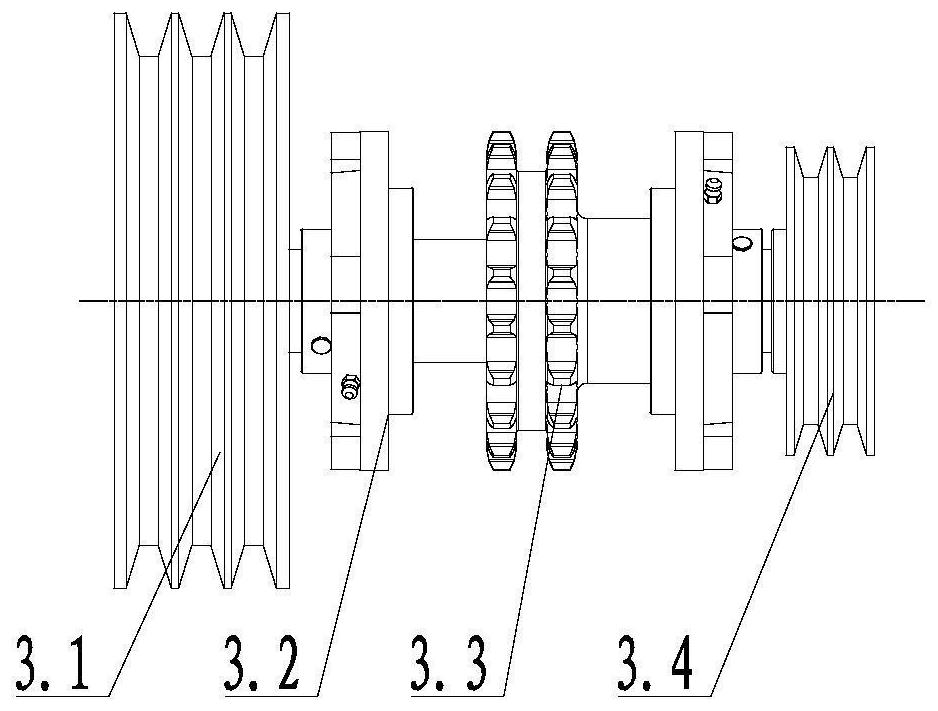

[0045] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 shown.

[0046] Corn ear cutting and grain crushing device consists of ear feeding box 1, ear cutting device 2, power input device 3, throwing device 4, throwing cylinder 5, conveying device 6, frame 7, grain crushing device 8, The shredding device housing and fixed knife 9 form. Among them, the chopping device is composed of a chopping power output pulley 2.1, a chopping knife shaft 2.2, a moving knife seat 2.3, a moving knife 2.4, and a chopping power input pulley 2.5; the power input device is composed of a pulley 3.1, a bearing seat 3.2, Power input sprocket 3.3, belt pulley 2 3.4; the conveying device consists of bearing housing 6.1, conveying shaft 6.2, auger blade 6.3, conveying shell 6.4, conveying power input pulley 6.5, throwing blade 4.1, throwing shell 4.2, The bearing housing 8.1, the crushing roller 8.2, and the shaft head 8.3 are composed.

[0047] The corn ear crushing device is compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com