Multi-stage step-by-step pulping equipment

A multi-stage and equipment technology, applied in the pulp beating method, etc., can solve the problems of insufficient beating and insufficient fineness, and achieve the effects of convenient mixing, simple structure, and prevention of liquid leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

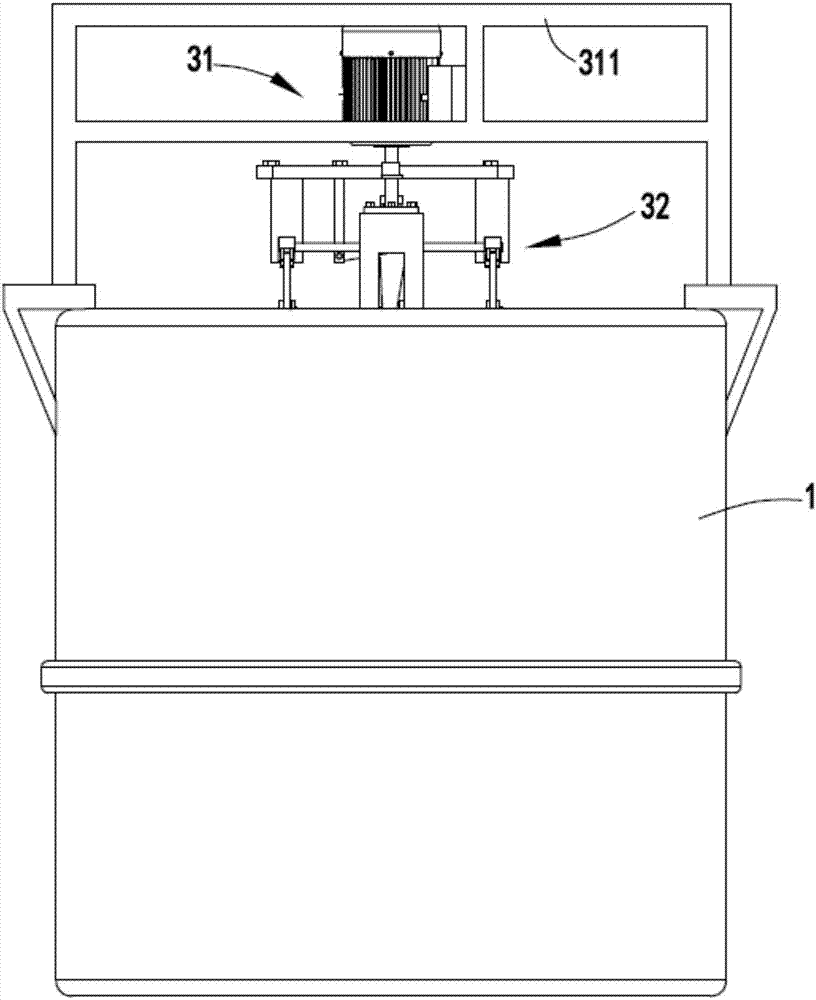

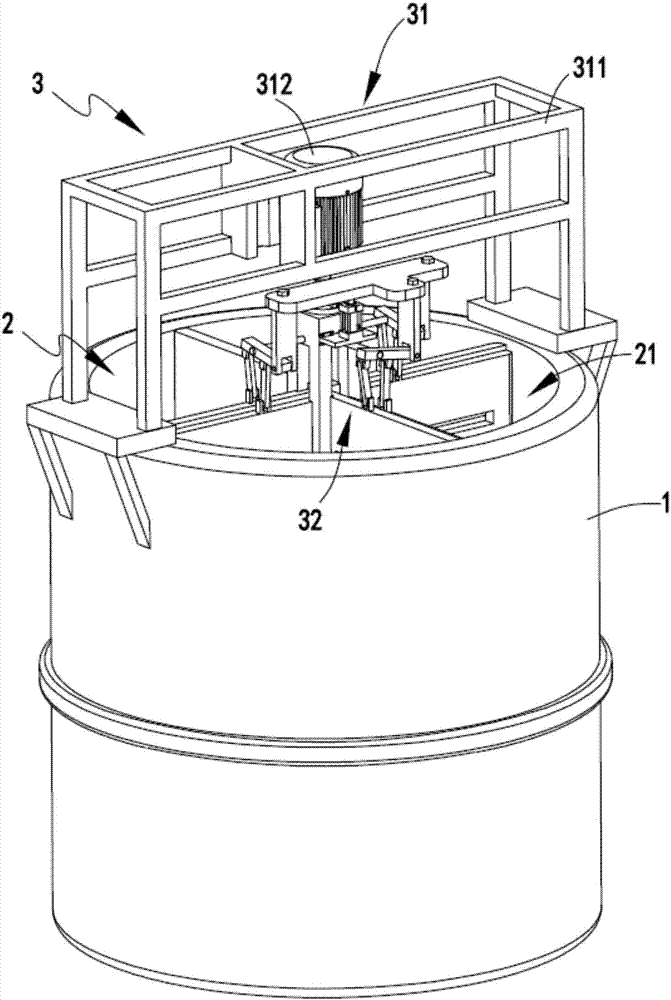

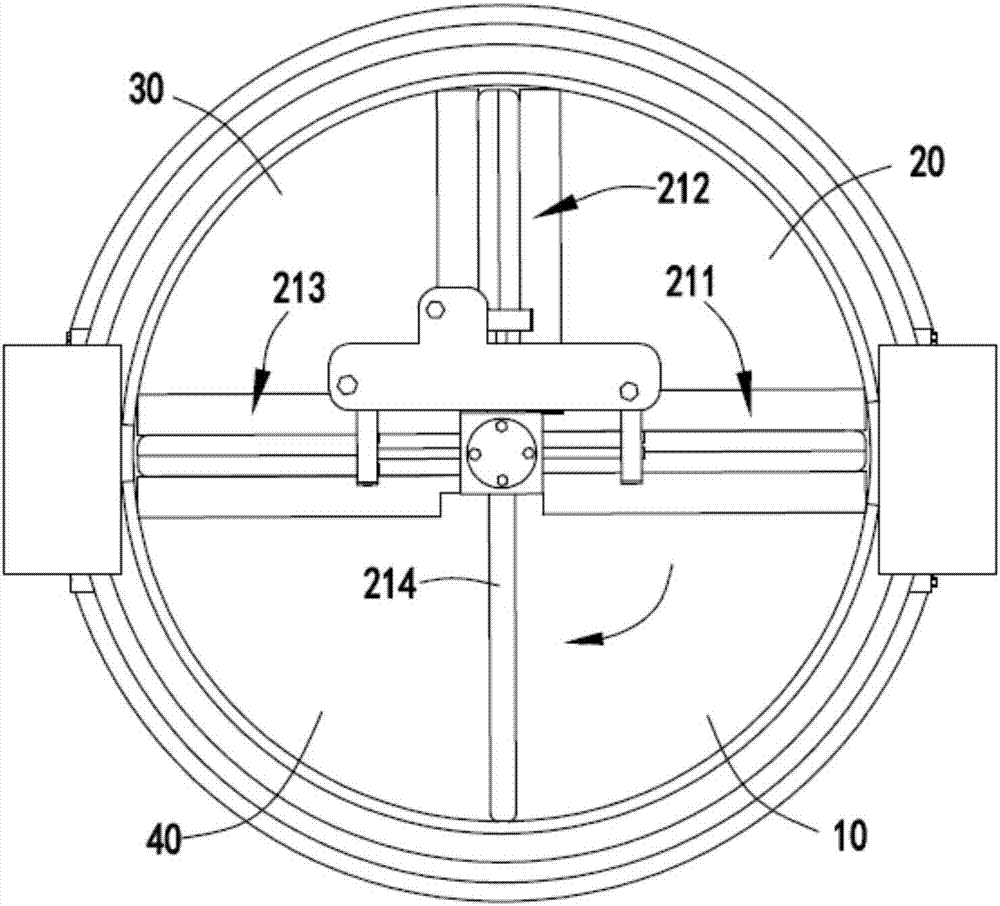

[0043] figure 1 It is a schematic diagram of the structure of the multi-stage beating equipment step by step, figure 2 It is a schematic diagram of the front view of the multi-stage step-by-step beating equipment, image 3 It is a top view schematic diagram of multi-stage step-by-step beating equipment, Figure 4 It is a structural schematic diagram of the beating mechanism and the lifting mechanism, Figure 5 It is a schematic diagram of the enlarged structure of the lifting mechanism, Image 6 It is a cut-away schematic diagram of the first-stage beating device, Figure 7 It is an enlarged schematic diagram of part of the structure of the primary beating device, Figure 8 It is a cut-away schematic diagram of the secondary beating device, Figure 9 It is an enlarged schematic diagram of part of the structure of the secondary beating device, Figure 10 It is a cut-away schematic diagram of the three-stage beating device, Figure 11 It is an enlarged schematic diagram of...

Embodiment 2

[0063] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 and Figure 13 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between the second embodiment and the first embodiment is: the first-level beating board a2211, the second-level beating board a2221, the third-level beating board a2231, the first-level beating board b2212, the second-level beating board b2222 and the third-level beating board The lower ends of b2232 are all provided with a supporting plate 8, and the upper surface of the supporting plate 8 is set in a wave shape;

[0064] By setting the supporting plate 8 and setting the upper surface of the tray 8 into a wave sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com