One-time straw chopping and stubble returning machine

A one-time, stubble-killing technology, applied in the field of machinery, which can solve the problems of nutrient loss, unsatisfactory work efficiency, and compaction of plots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

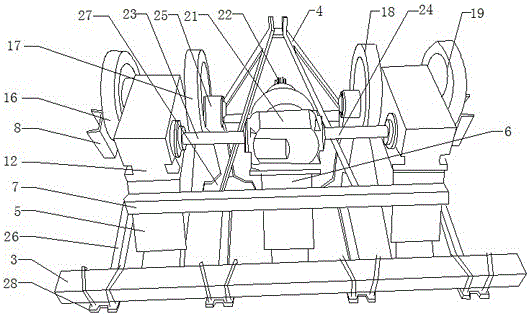

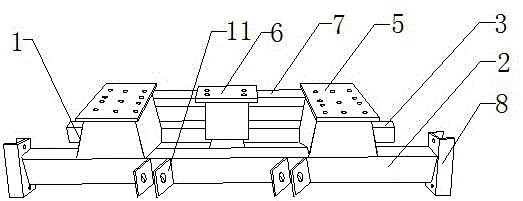

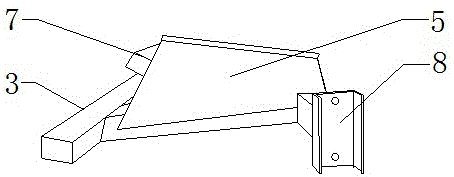

[0026] Such as Figure 1-2 As shown, a machine for one-time shredding and stubble returning to the field. The frame 1 is composed of a front beam 2 and a rear beam 3. A flower stand 4 connected with an agricultural machine is arranged in the middle of the frame 1. The front beam 2 of the frame is Bearing blocks 5 are respectively arranged on both sides of the upper side of the rear crossbeam 3, and a transmission shaft seat 6 is also arranged at the middle position between the bearing blocks 5 on both sides of the upper side of the frame 1. After the bearing seat 5 and the transmission shaft seat 6 A fixed crossbeam 7 is arranged on the side, and connecting seats 8 are respectively arranged at the left and right ends of the front crossbeam 2 of the frame 1 . The overall frame of the frame body is a welded integrated structure. The bearing seat 5 and the transmission b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com