Method for producing gasoline and low-sulfur ship fuel

A low-sulfur ship and gasoline technology, which is applied in the processing of hydrocarbon oil, petroleum industry, hydrocarbon oil processing products, etc., can solve the problems of re-refined oil and oil slurry not being fully utilized, difficult diesel processing, and low gasoline yield , to achieve the effect of improving logistics distribution and mass transfer, reducing equipment investment and operating energy consumption, and reducing metal content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

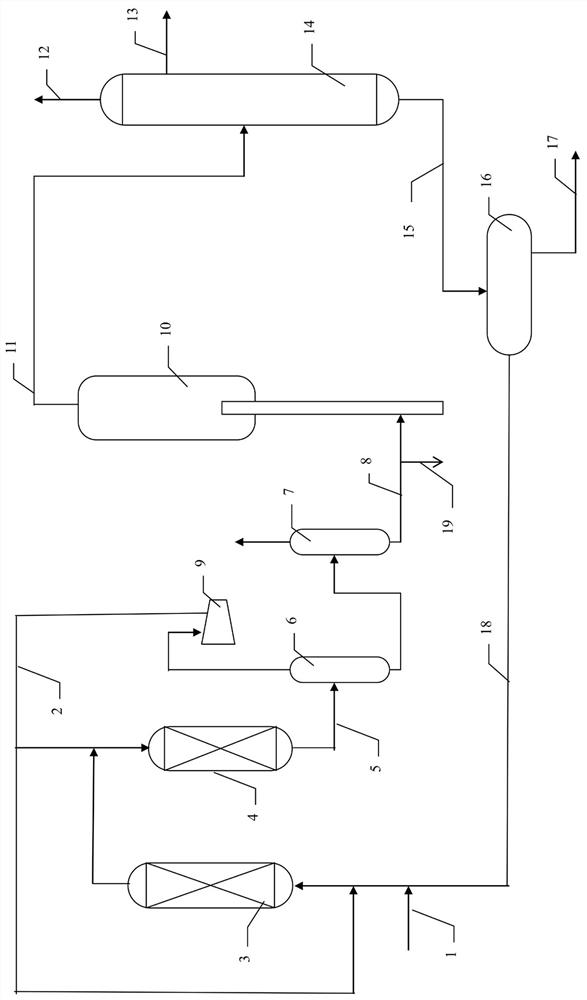

[0046] In this example, the method for producing gasoline and low-sulfur marine fuel provided by the present invention is adopted, and the raw material A of the inferior residual oil is used. It can be seen that the sulfur content of the residual oil is as high as 5.12wt%, the residual carbon is 17.50wt%, and the metal (Ni+V) is 226µg. / g, the total nitrogen content is 0.38%, which belongs to high-sulfur inferior residue oil.

[0047] The hydrogenation unit is composed of one fluidized bed and four fixed-bed reactors connected in series. The fluidized bed reactor is filled with catalyst F in Table 2, and the filling volume is 334 mL. The first fixed bed was loaded with three kinds of residual oil hydrogenation protective agents, and the filling volume was 10 mL of FZC-12B catalyst, 15 mL of FZC-103D catalyst, and 35 mL of FZC-103E catalyst; the second fixed bed was loaded with two kinds of residual oil hydrogenation demetallization catalysts. , the filling volume is 45mL of FZ...

Embodiment 2

[0050] Embodiment 2 adopts the method for producing gasoline and low-sulfur marine fuel provided by the present invention, adopts inferior residual oil raw material B, and the properties of residual oil raw material are shown in Table 1. It can be seen that the sulfur content of the residue is 4.20wt%, the nitrogen content is 3972µg / g, the Kang's carbon residue is 15.20wt%, and the metal (Ni+V) is 169µg / g.

[0051] The hydrogenation unit is composed of one fluidized bed and four fixed-bed reactors connected in series, wherein the fluidized bed reactor is filled with the catalyst F in Table 2, and the filling amount is 278 mL. The fixed bed was filled with three kinds of residual oil hydrogenation protection agents in the first reverse, and the filling volumes were 15 mL of FZC-12B catalyst, 15 mL of FZC-103D catalyst, and 30 mL of FZC-103E catalyst; The volume is respectively 30mL of FZC-28A catalyst and 170mL of FZC-204 catalyst; three anti-loading of a residual oil hydrodesu...

Embodiment 3

[0054] The same as in Example 1, the difference is that the catalyst in the hydrogenation device is filled in the following way: wherein the fluidized bed reactor is filled with the catalyst F and the filling amount is 308 mL. Three reactors were set up in the fixed bed with accumulative filling of 423 mL, and two kinds of residual oil hydrogenation protection agents were loaded in one reverse direction. The filling volumes were 10 mL of FZC-12B catalyst and 20 mL of FZC-103E catalyst; Metal catalyst, the filling volume is 100mL for FZC-28A catalyst, and 130mL for FZC-204 catalyst; the three-reverse filling is a residue hydrodesulfurization catalyst FZC-34A, and the filling volume is 163mL.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com