Solar spectral photosynthetic bioreactor system for culturing microalgae in high density

A technology for photobioreactor and high-density cultivation, which is applied in the direction of photobioreactor, specific-purpose bioreactor/fermenter, combination of bioreactor/fermenter, etc. Difficulties and other problems, to achieve the effect of reducing power consumption, continuous and stable cultivation, and improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

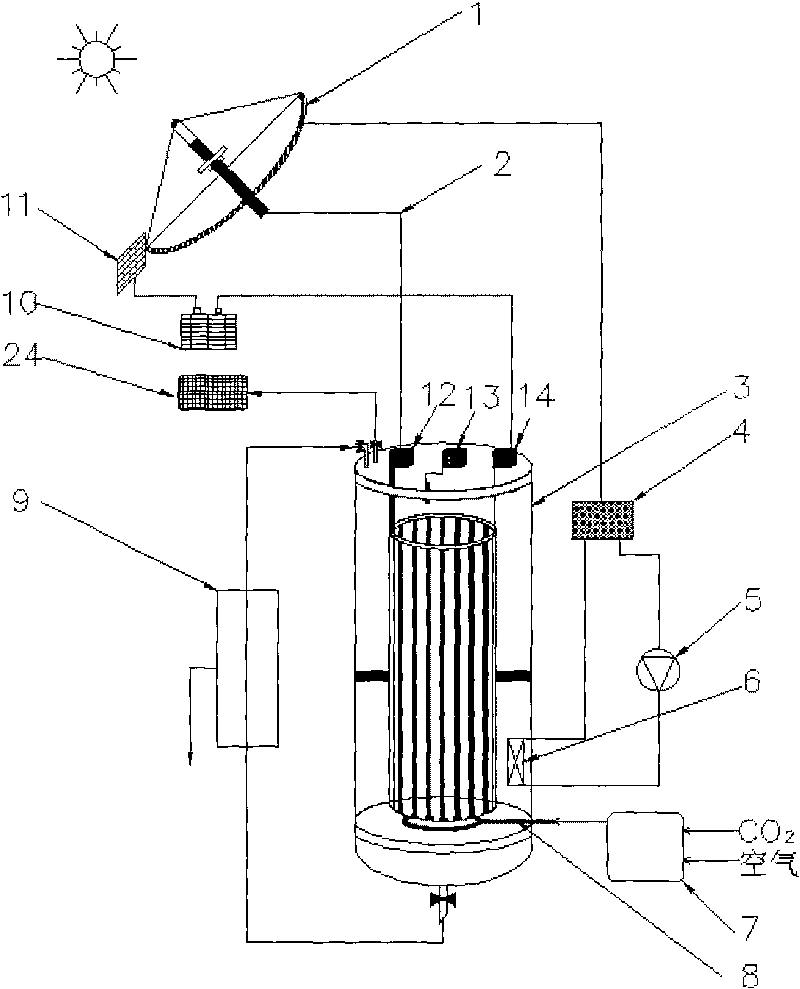

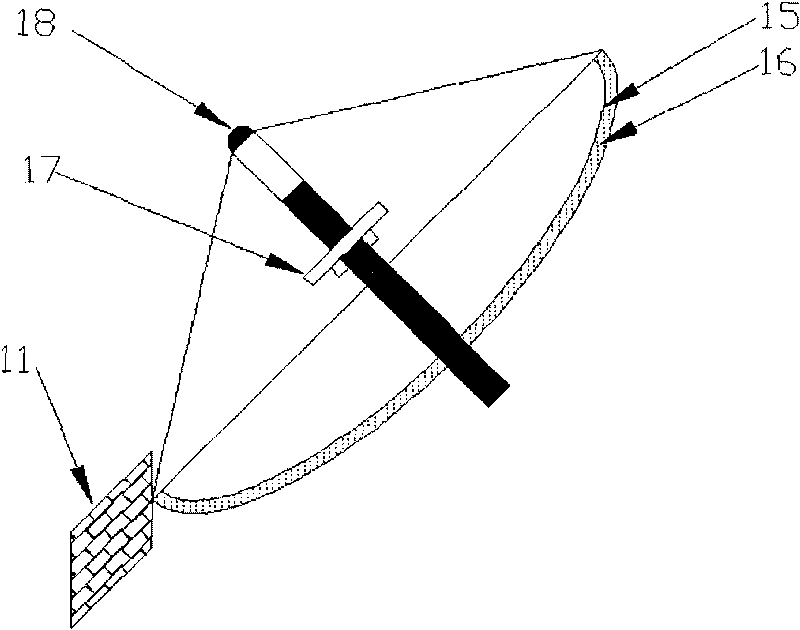

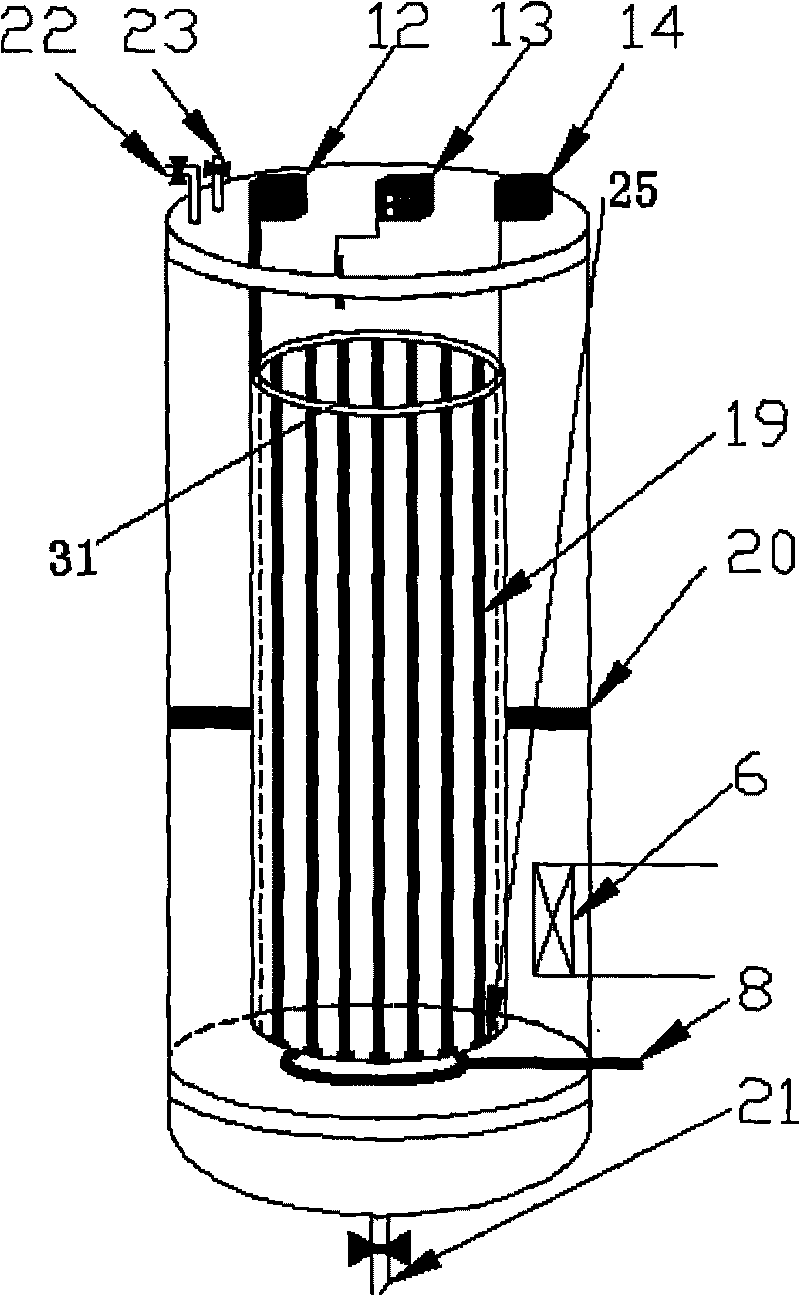

[0026] see Figure 1 to Figure 4 As shown, a solar light-splitting photosynthetic bioreactor system for cultivating microalgae at high density includes a photobioreactor 3, a solar collector 1, an optical fiber 2, and a light distribution device arranged in the photobioreactor 3 , the residual gas absorption device 24 and the culture fluid separation and recovery device 9 connected to the photobioreactor 3 respectively; The device 12 is connected to the solar collector 1 through an optical fiber 2; a gas distributor 8 is provided between the light distribution device and the bottom of the photobioreactor 3, and the gas distributor 8 is connected to the gas mixing device 7.

[0027] In the present embodiment, the photobioreactor 3 is made of a transparent PMMA (polymethyl methacrylate, i.e. organic glass) cylindrical tank (the reactor is designed to withstand a pressure of 0.2MPa). 3 is also coaxially provided with an inner cylinder 31 made of double-layer transparent PMMA sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com