Reasonable catalytic combustion thermal energy distribution method and equipment of enameling machine

A catalytic combustion, enameling machine technology, applied in the combustion method, combined combustion mitigation, lighting and heating equipment, etc., can solve the problem of not carefully considering the quality of enameled wire, not solve the problem of reasonable heat distribution in the furnace, no heat supply and other problems, to achieve Easy to install and debug, speed up the baking progress, save electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

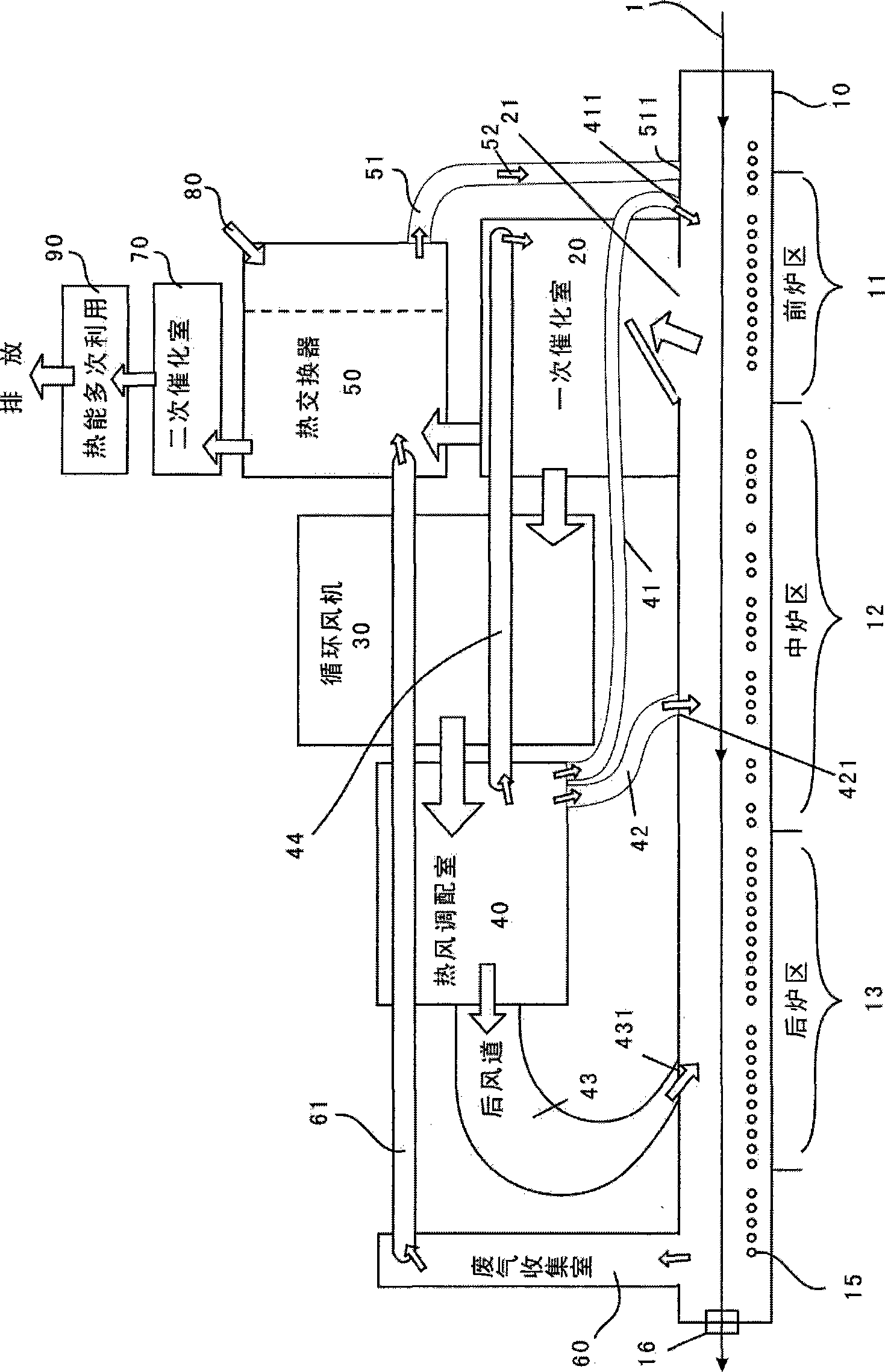

[0056] Such as figure 1 shown in the preferred embodiment,

[0057] Implement a method for rationally distributing catalytic combustion heat energy of an enamelling machine, said method is based on the main furnace body 10, circulating fan 30, heat exchanger 50 and primary catalytic chamber 20 installed with main furnace heating pipe 15; said main furnace heating pipe 15 is used in the preheating process. After the catalytic combustion heat energy reaches a normal cycle, the main furnace heating tube 15 is powered off;

[0058] The method comprises the steps of:

[0059] A. Firstly, a circulation fan 30 is set above the main furnace body 10 near the middle, and a catalytic chamber 20 is set above the main furnace body 10 near the front;

[0060] B. The circulation fan 30 sends the circulating hot air after catalytic combustion into the hot ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com