Magnet protection system for power fail of electromagnet

A technology of electromagnet and magnetic protection, applied in the direction of electromagnet with armature, electromagnet, battery circuit device, etc., can solve the problems of easy damage, accident, temperature drift phenomenon, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

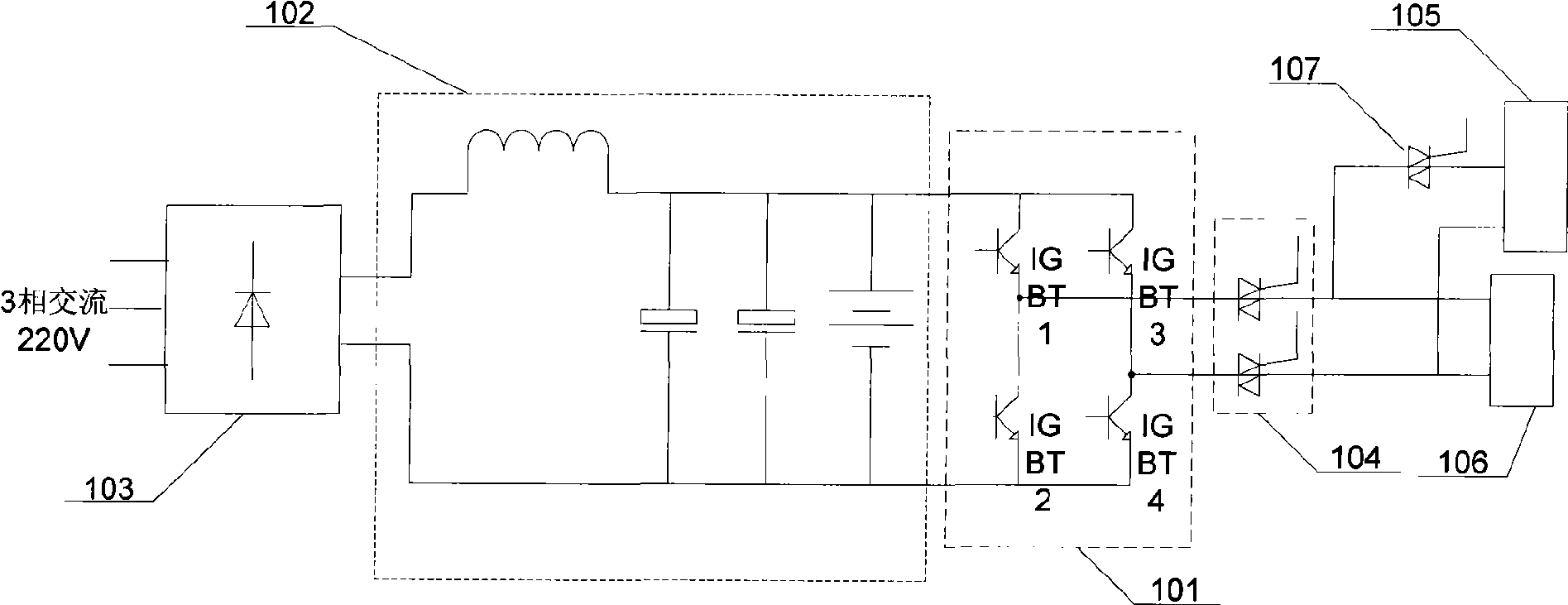

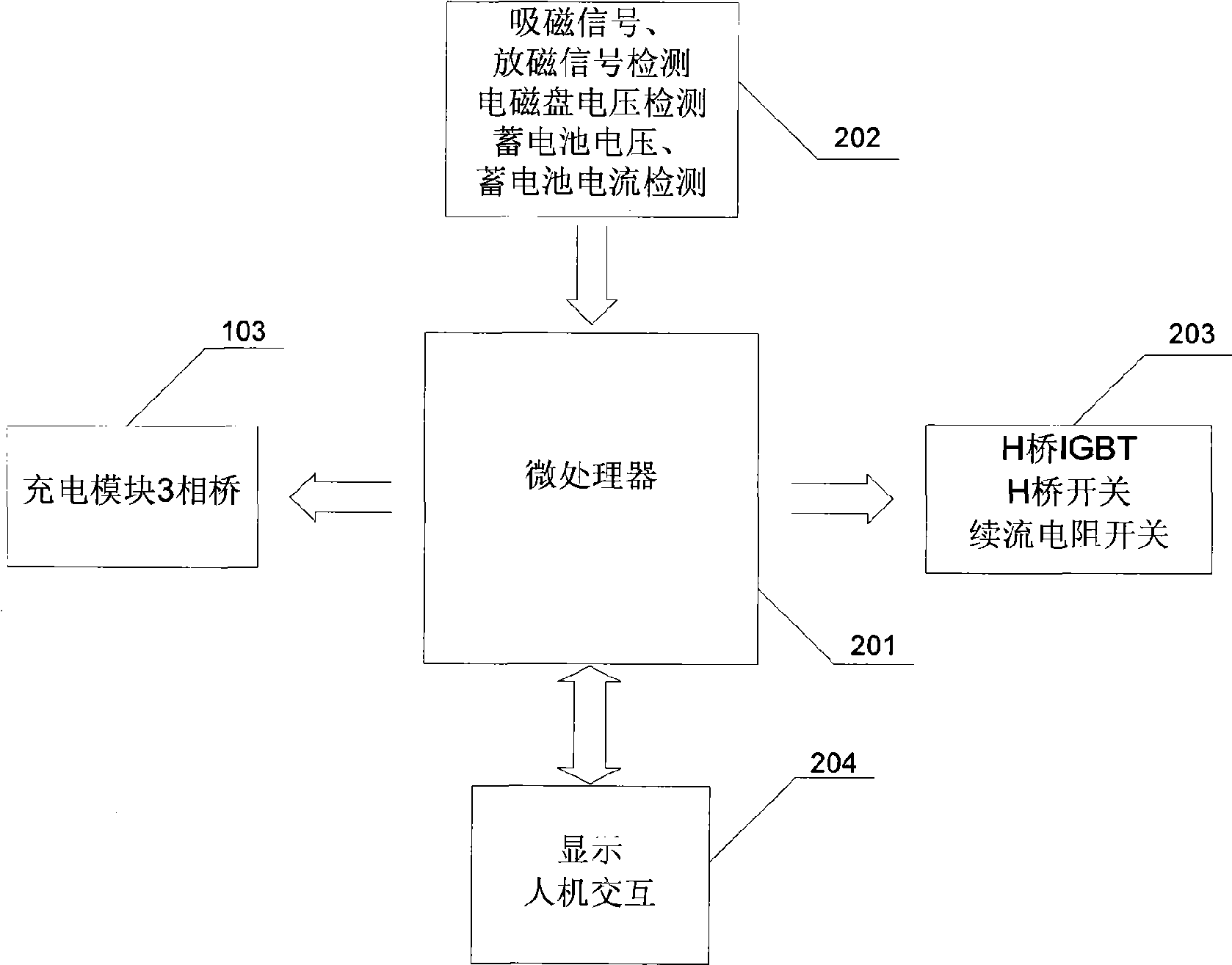

[0026] Such as figure 1 , figure 2 Shown is the schematic structural diagram of the magnetic holding device after the electromagnet is powered off and the structural block diagram of the electric control system, the operation and display unit 204 is used to input operation information to the magnetic holding device and display the working status of the whole device, wherein the display unit adopts LCD Chinese characters display, maintenance personnel can easily know the working status of the device, making maintenance very simple and fast, by reading the display content of the liquid crystal on the display panel of the charging and magnetic retention switching device, you can quickly know the charging and magnetic retention switching device As well as the problem of the entire electrical system, the on-site maintenance personnel can quickly find the fault point, thereby greatly shortening the maintenance time, reducing the difficulty of maintenance, reducing the maintenance c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com