Tooling vehicle for transillumination inspection of aero-engine case

A technology for aero-engines and tooling vehicles, which is applied to vehicles, motor vehicles, trolleys, etc. used for freight transportation, can solve the problem that the detection tooling cannot meet the multi-angle and partitioned transillumination detection requirements of large thin-walled casings, and achieves a reduced detection rate. Strength, saving space on the site, and widely promoting the effect of application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

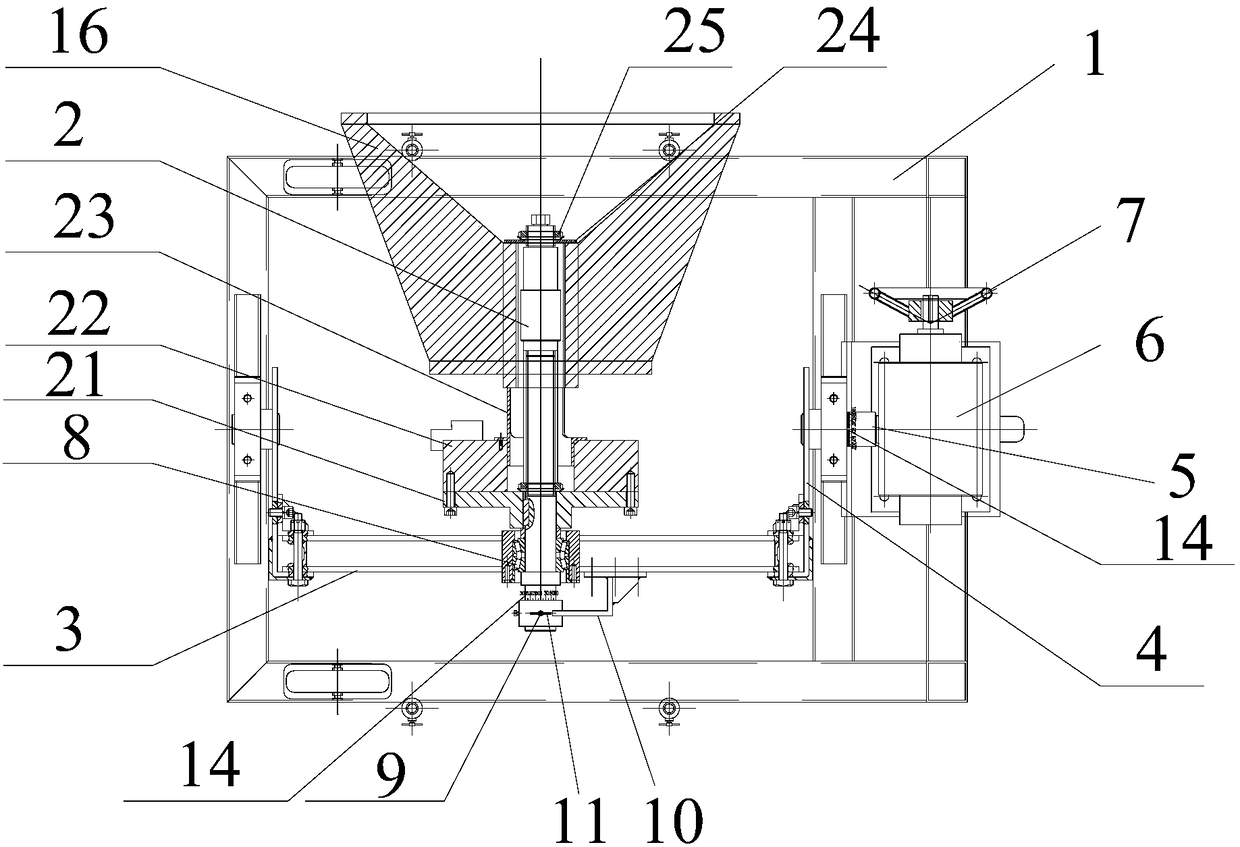

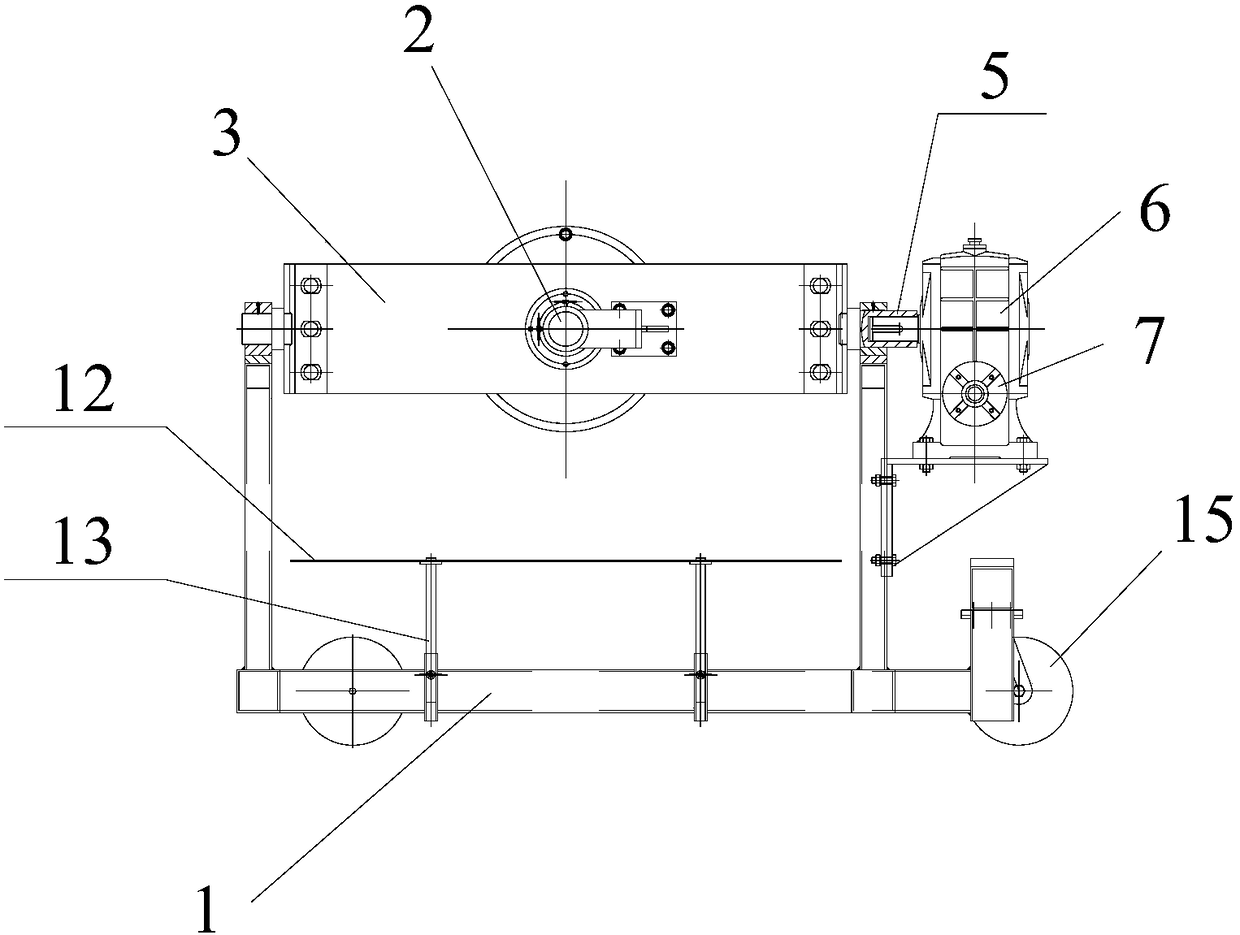

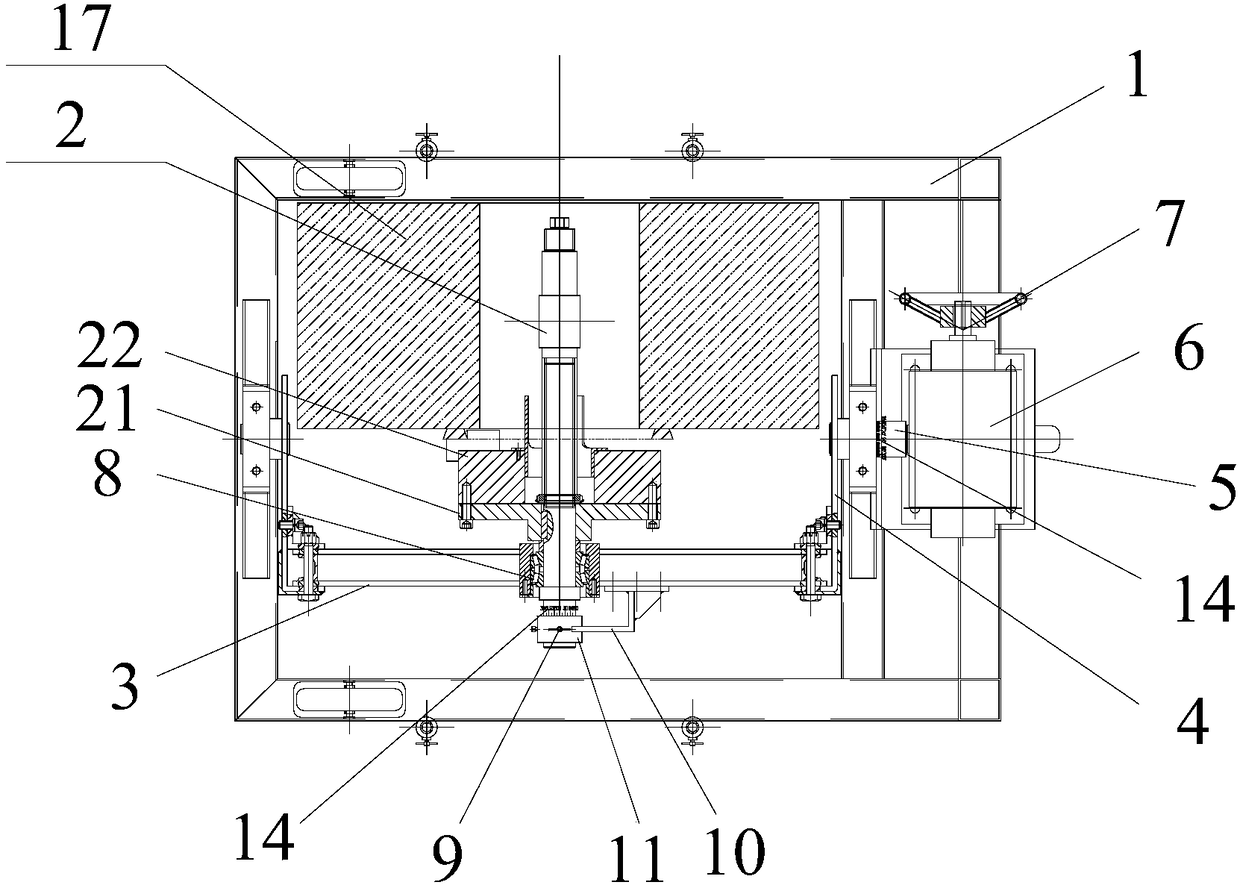

[0043] refer to Figure 1 to Figure 3 A preferred embodiment of the present invention provides a tooling vehicle for the transillumination detection of an aero-engine casing, the tooling vehicle includes a car body 1 and a frame mounted on the car body 1 for installing and fixing the casing to be detected by transillumination. The first transmission shaft 2, the first transmission shaft 2 is provided with a clamping part for cooperating with the mounting part of the casing to clamp the casing, the first transmission shaft 2 is connected to the support frame 3, and the support frame 3 passes through the rocker arm 4 is connected to the second transmission shaft 5 for driving the supporting fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com