Forming method of crystalline plastic

A molding method and crystalline technology, applied in the field of crystalline plastic molding, can solve the problems of high equipment and labor costs, whitening of the surface of the molded body, and increase equipment costs, saving labor and process time, and improving profitability and efficiency. Competitiveness, the effect of reducing equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to further understand the structure, features and other purposes of the present invention, the preferred embodiments of the present invention are listed below, and are described in detail with the accompanying drawings, so that those skilled in the art can implement them.

[0022] The present invention is a molding method of crystalline plastics. The accompanying drawings illustrate specific embodiments of the present invention and its components, all about front and rear, left and right, top and bottom, upper and lower, and horizontal and vertical References are made for convenience of description only and do not limit the invention, nor its components, to any position or orientation in space. The dimensions specified in the drawings and description can be changed according to the design and requirements of the specific embodiments of the present invention without departing from the patent scope of the present invention.

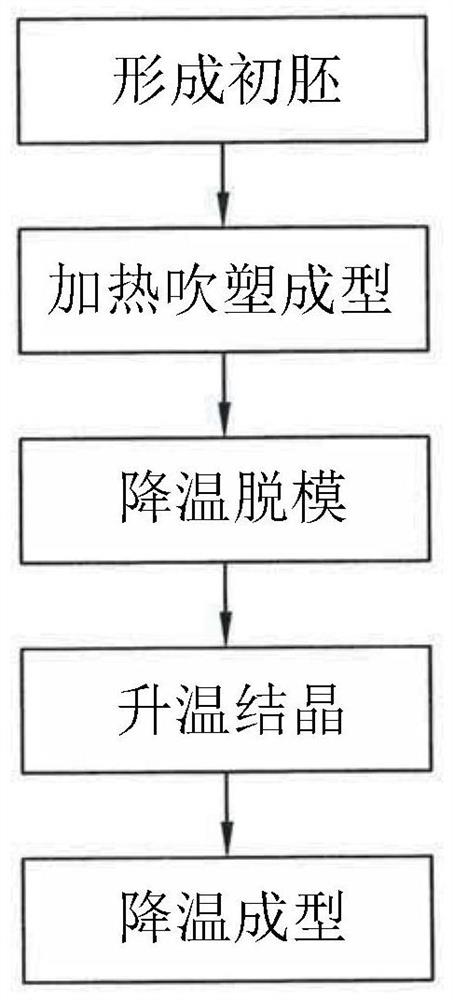

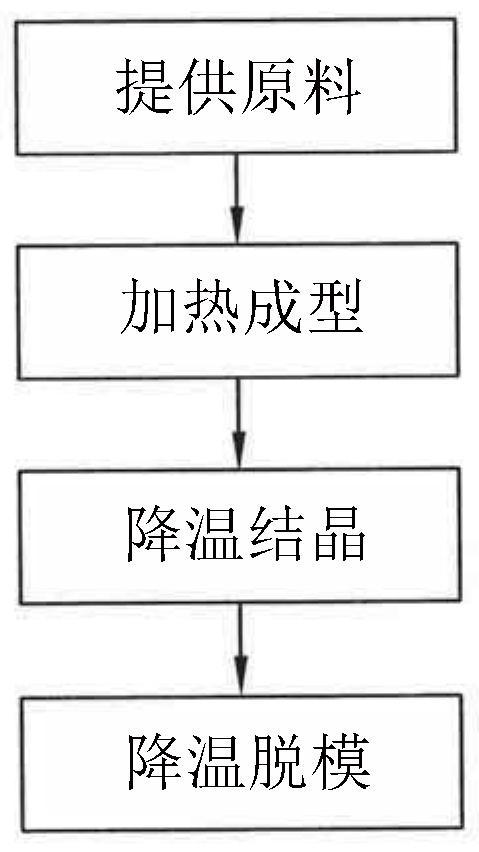

[0023] The molding method of crystall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com