Method for decreasing phosphorus of high-phosphorus iron ore by adopting microwave reduction-magnetic separation

A high-phosphorus iron ore and microwave technology, which is applied in the field of high-phosphorus iron ore reduction and phosphorus reduction, can solve the problems of slow dephosphorization speed, low iron recovery rate and dephosphorization rate of high-phosphorus iron ore, and achieve the carbon thermal reduction time short, low reduction temperature, and increased iron recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be specifically described below by taking a laboratory small-scale test as an example.

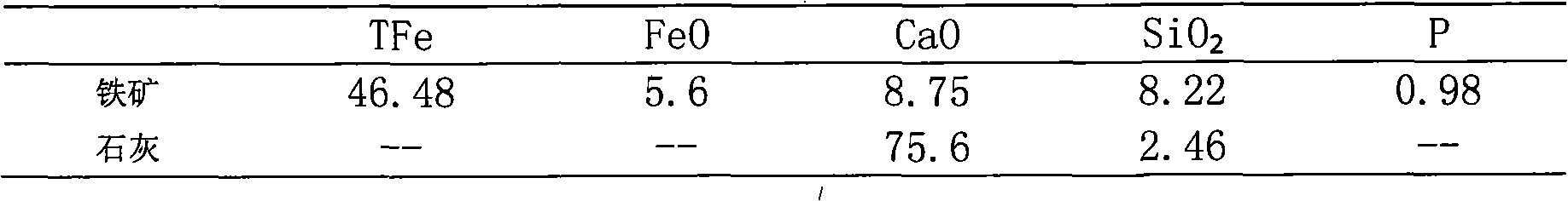

[0017] Take high phosphorus iron ore powder and slaked lime, the chemical composition of high phosphorus iron ore and slaked lime is shown in Table 1; the reducing agent is coal powder, and the composition of coal powder is shown in Table 2; the reduction microwave oven uses KH-6HMOA industrial microwave oven.

[0018] Table 1 Ferrophosphorite and slaked lime chemical composition (%)

[0019]

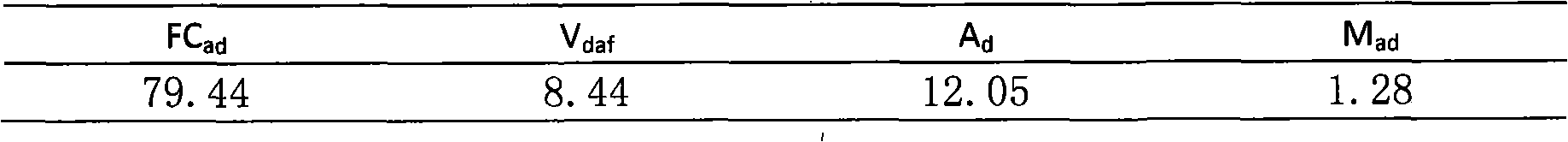

[0020] Table 2 Industrial analysis of pulverized coal composition (%)

[0021]

[0022] Implementation steps:

[0023] (1) Use a ball mill to finely grind coal powder and high-phosphorus iron ore powder into 90 mesh to 1mm.

[0024] (2) Weigh 82.5g of the above-mentioned high-phosphorus iron ore powder, 15.2g of coal powder, and 2.28g of slaked lime and mix them well, and spread the coal powder on the top layer to prevent the sample from being oxidized when ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com