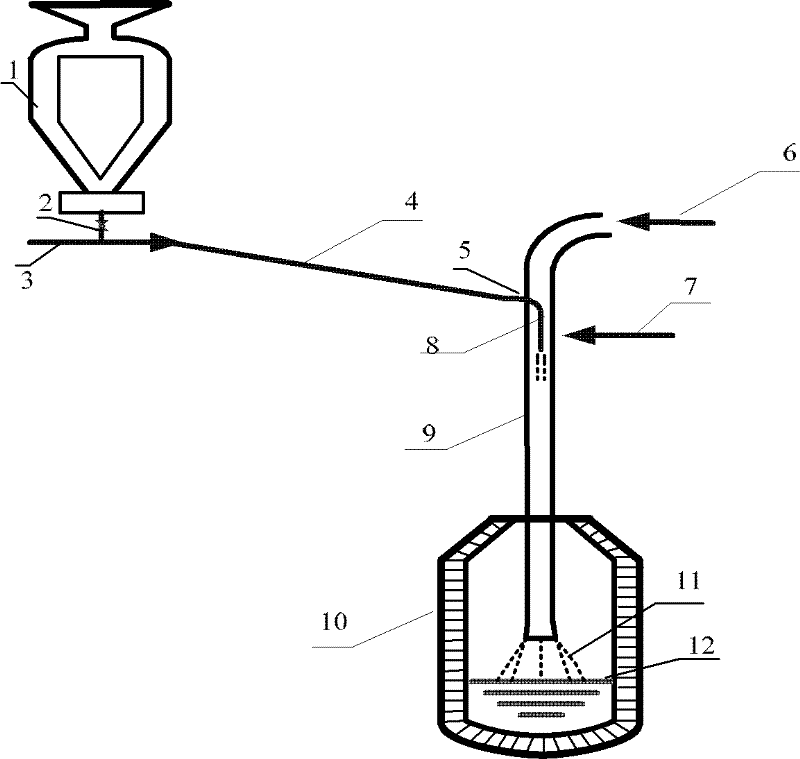

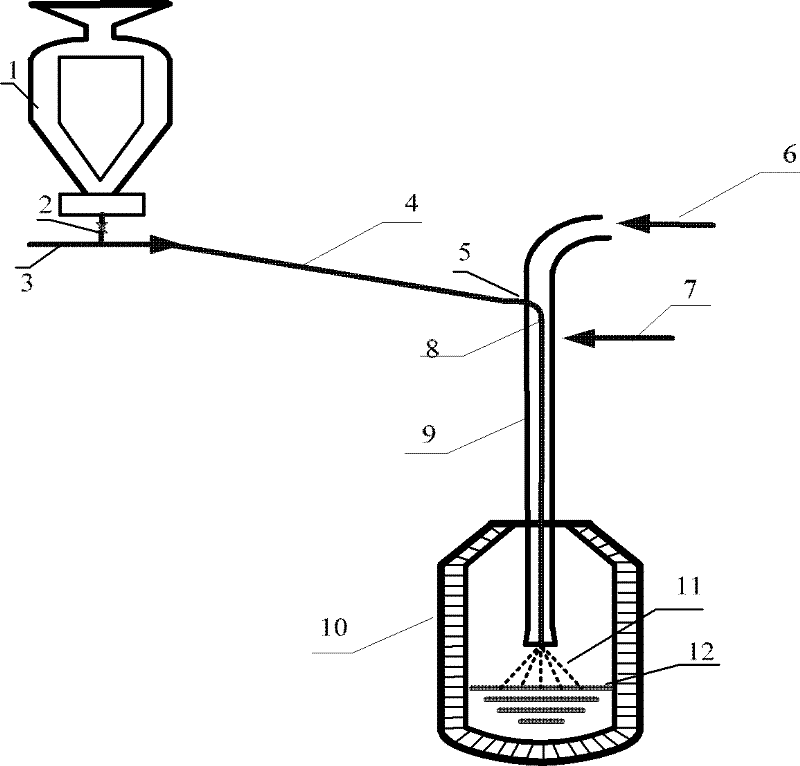

Converter steelmaking method through power injection dephosphorization by adopting supersonic speed oxygen lance and supersonic speed oxygen lance

A converter steelmaking and supersonic technology, applied in the manufacture of converters, etc., can solve problems such as difficulty in meeting the requirements of rapid slagging and dephosphorization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

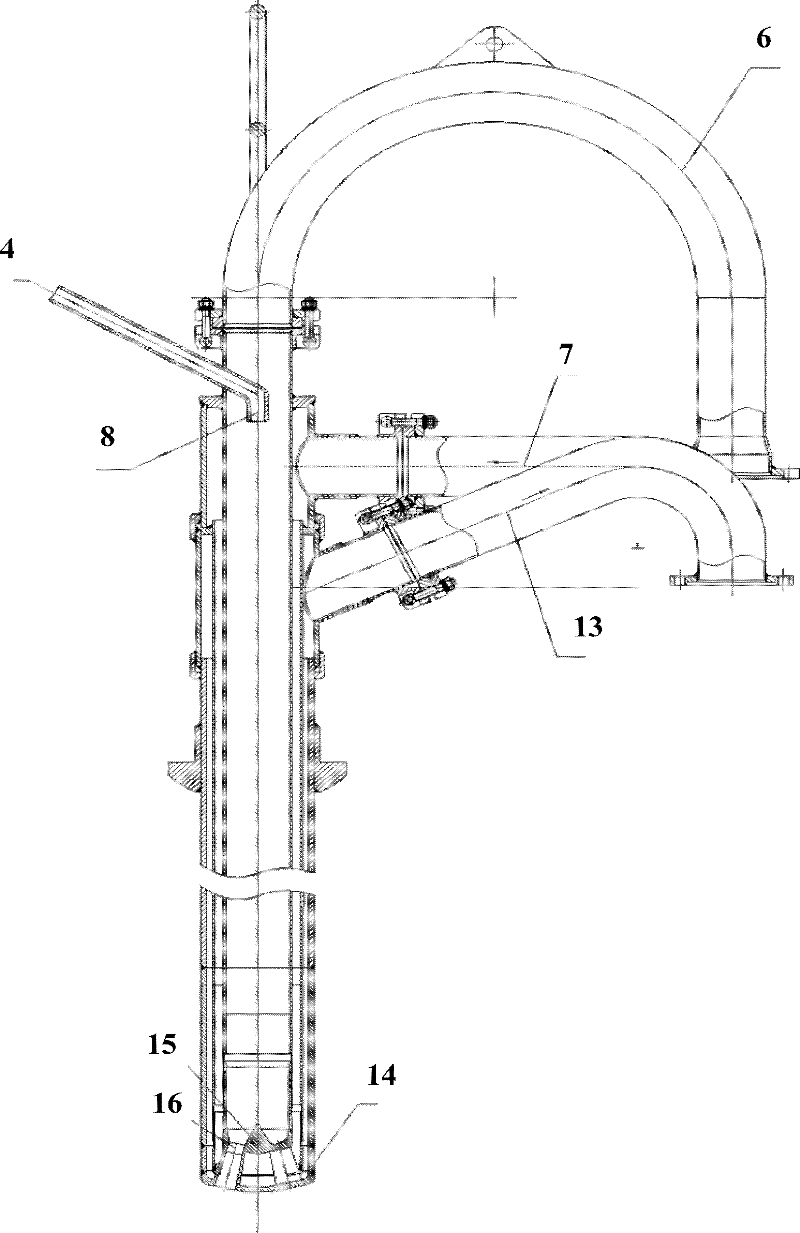

[0041]This embodiment is used in a 120-ton converter. Wear-resistant ceramic hoses are used to connect the powder outlet of the powder spraying equipment with the powder inlet on the oxygen lance body. The bend introduces the oxygen blowing central pipe, and the outlet of the powder supply pipe is located at the nozzle. The nozzle Mach number is 1.9. The oxygen flow rate of the oxygen inlet tube is 25000-28000Nm 3 / h, the pressure is 0.65-0.85MPa. The supersonic jet powder is limestone powder with a particle size of less than 2mm.

[0042] Specific smelting operation process:

[0043] In the early stage of smelting: the flow rate of limestone powder injection is 200-220kg / min, and the flow rate of conveying carrier gas is 1500Nm 3 / h, at the same time add some lime, after adding magnesium balls, slagging agent, fluorite and other slag-forming materials, use a high gun position of 1.8-2.0m to operate, which is beneficial to slagging and dephosphorization in the steelmaking ...

Embodiment 2

[0049] This embodiment is used in a 300-ton converter. A wear-resistant ceramic hose is used to connect the powder outlet of the powder spraying equipment with the powder inlet of the oxygen lance body. The powder supply pipeline is made of wear-resistant stainless steel with a size of φ120×5mm. The channel is introduced into the inner tube of the oxygen lance with a length of 180mm, and the powder inlet of the powder supply pipeline is located at the lower end of the oxygen inlet tube at 100mm. The nozzle of the oxygen lance has a constriction section and a throat made of tungsten-copper alloy, and the Mach number of the nozzle is 2.05. The oxygen flow rate of the oxygen inlet tube is 65000-69000Nm 3 / h, the pressure is 0.80-0.95MPa. The particle size of the sprayed lime powder is less than 5mm.

[0050] Specific smelting operation process:

[0051] In the early stage of smelting: the flow rate of lime powder injection is 450-500kg / min, and the flow rate of carrier gas for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com