Circulation injection method and system for preparing CO2 through converter gas

A converter gas and CO2 technology, applied in the preparation of oxides/hydroxides, manufacturing converters, reducing gas emissions, etc., can solve the problems of increased separation, purification and preparation costs, many impurities, and low content, and achieves a reduction in Purify the preparation cost, improve the dephosphorization rate, and enhance the effect of molten pool stirring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

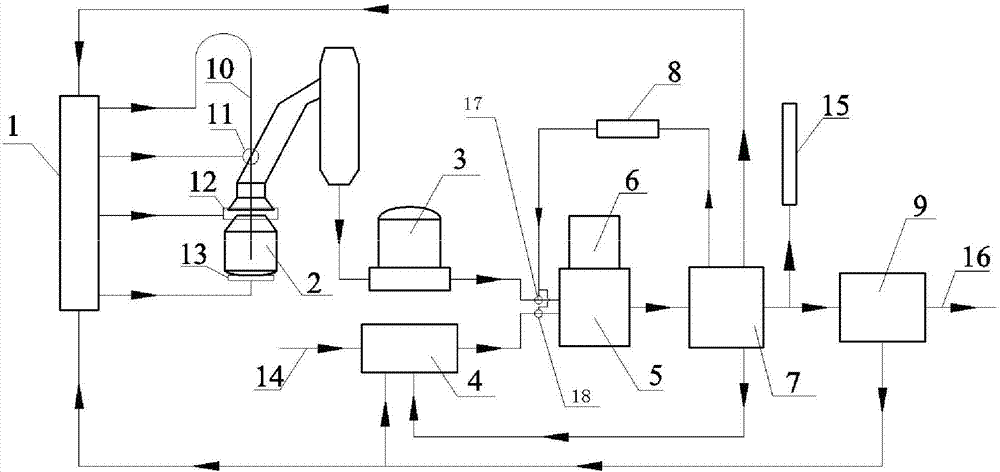

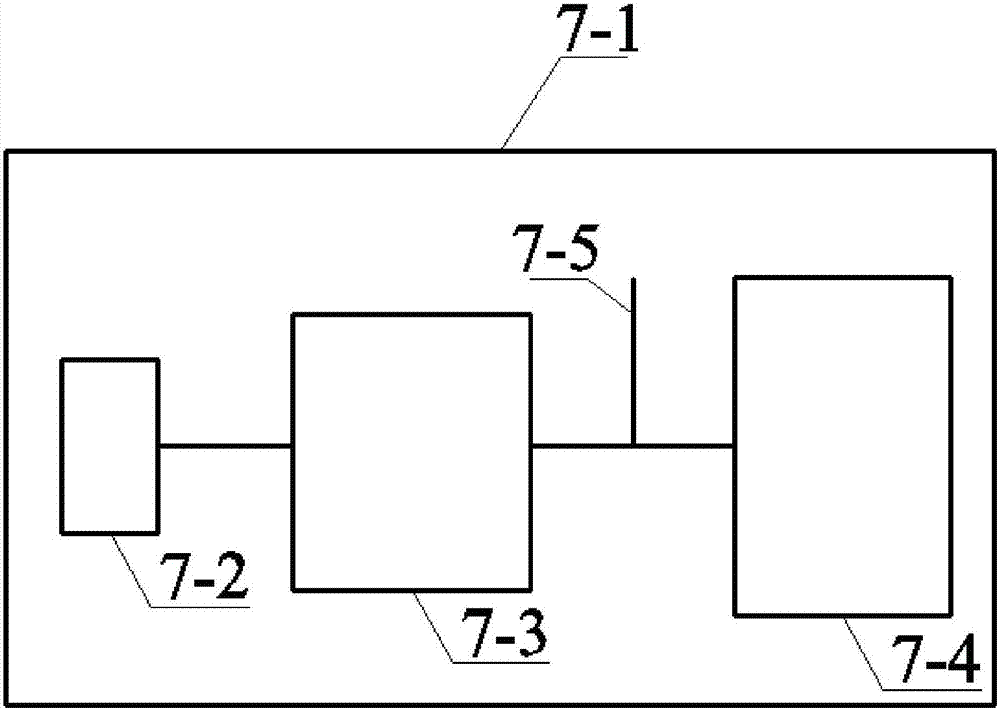

[0057] A method for producing CO from converter gas 2 And the method of circulating injection, using low N 2 content of converter gas and O 2 , CO 2 The oxidant as the main component is burned in the gas combustion device, and the combustion heat is utilized through the heat exchange device, and the combustion flue gas is purified to obtain CO-rich 2 of pure flue gas, which is rich in CO 2 The pure flue gas is defined as low-purity CO 2 , part of the low-purity CO 2 Used for purification and preparation of high-purity CO 2 ; the low-purity CO 2 and high-purity CO 2 It is circulated to the converter gas supply system for converter top blowing, converter bottom blowing and converter sealing protection, which can obtain the low N 2 content of converter gas; the low-purity CO 2 and high-purity CO 2 is circulated to the oxidant gas distribution cabinet, and industrial pure O 2 O 2 , CO 2 as the main component of the oxidizing agent; the low-purity CO 2 and high-purity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com