Method for smelting low-phosphor steel based on high-silicon molten iron converter double-slag process

A double-slag method, low-phosphorus steel technology, applied in the field of iron and steel smelting, can solve the problems of rising molten pool temperature, early carbon-oxygen reaction, difficulty in smelting, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

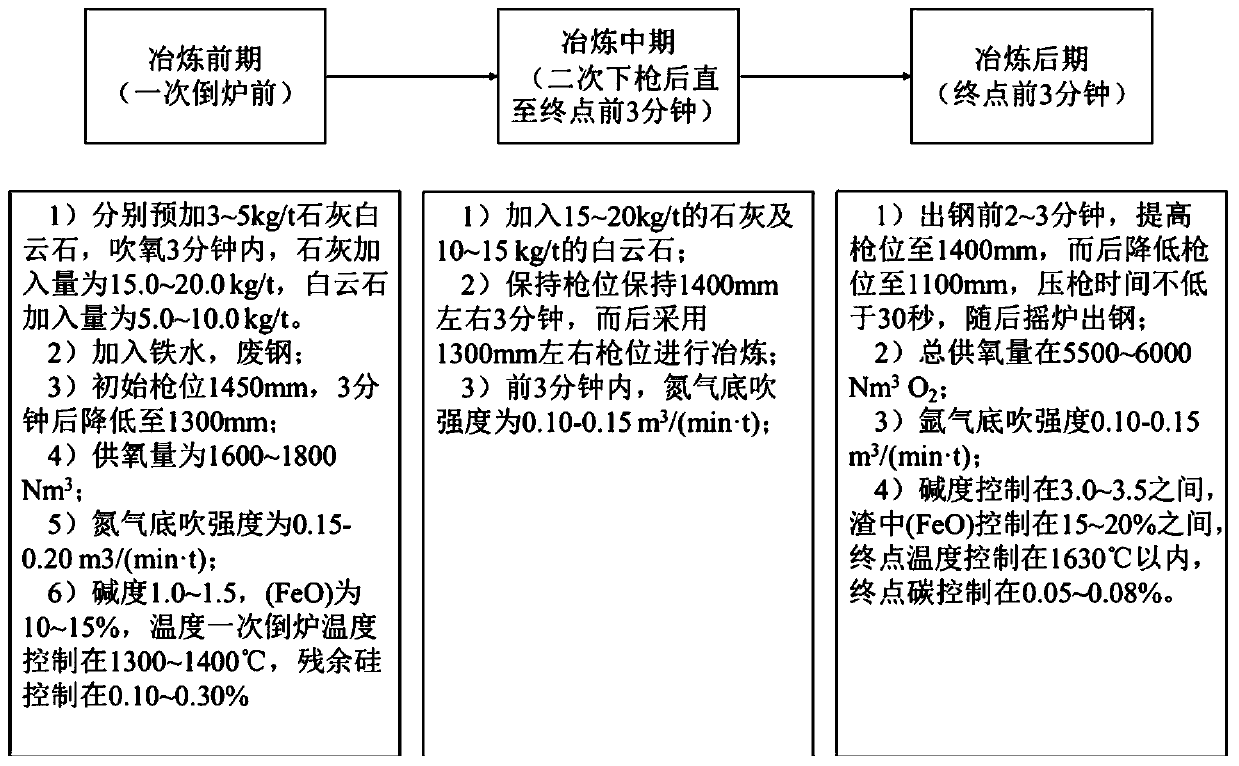

Method used

Image

Examples

Embodiment 1

[0057] The Si content of the molten iron is 1.23%, the C content of the molten iron is 4.37%, the P content of the molten iron is 0.165%, the temperature of the molten iron is 1322°C, and the converter double slag method is used for operation. According to the Si content of molten iron, the amount of molten iron in the desiliconization furnace is set to 100t, the amount of scrap steel to be loaded is 28t, and the oxygen supply in the early stage is set to 2000Nm 3 o 2 , the total oxygen supply is set to 6000Nm 3 o 2 .

[0058] Add 4.43kg / t of lime and 4.50kg / t of dolomite before blowing, add 17.56kg / t of lime, 7.35kg / t of dolomite and 8.15kg / t of iron ore before blowing 30% oxygen. When the amount of oxygen blowing reaches the set value, the gun is lifted and the furnace is turned down to discharge the acid slag in the early stage. The primary furnace temperature is 1330°C, the silicon content is 0.132%, the carbon content is 3.18%, and the phosphorus content is 0.135%. A...

Embodiment 2

[0068] Compared with Example 1, this experimental example is only different in the silicon content of molten iron, the scrap ratio, the addition of smelting slag, the tapping temperature, and the carbon and phosphorus content at the end point. The Si content of the molten iron is 1.10%, the C content of the molten iron is 4.53%, the P content of the molten iron is 0.132%, the temperature of the molten iron is 1321°C, and the double slag method of the converter is used for operation.

[0069] The Si content of molten iron in this heat is 1.10%, so the steel scrap ratio is lower than the setting, the charging amount of molten iron is set at 100t, the charging amount of scrap steel is set at 25t, and the oxygen supply in the early stage is set at 1900Nm 3 o 2 , the total oxygen supply is set to 6000Nm 3 o 2 .

[0070] Add 4.41kg / t of lime and 4.50kg / t of dolomite before blowing, and add 15.12kg / t of lime, 5.75kg / t of dolomite and 6.42kg / t of iron ore before 30% oxygen blowing....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com