Multistage combined pretreatment method for vanadium-bearing molten iron

A combined pretreatment technology, which is applied in the field of pig iron refining, can solve the problems of unreasonable furnace charge structure, heavy blast furnace load, and large consumption, and achieve the effects of reducing lime consumption, reducing desulfurization load, and liberating blast furnaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

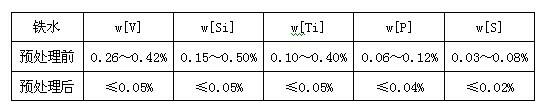

Method used

Image

Examples

Embodiment 1

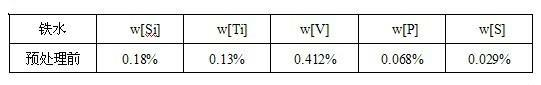

[0024] The amount of molten iron in the molten iron package is 162 tons, and the composition of the molten iron is shown in the table below:

[0025]

[0026] First, hoist it to the desulfurization station for desulfurization treatment. The desulfurization results and process parameters are shown in the following table:

[0027]

[0028] The molten iron after desulfurization is mixed into the vanadium extracting converter, and 15 tons of iron nuggets are added to carry out blowing with oxygen supply. The process control and end point are as follows:

[0029]

[0030] Then carry out semi-steel tapping operation (the semi-steel tapping volume is 169 tons), the semi-steel tapping time is 4 minutes, and the working pressure of nitrogen blowing at the bottom of the ladle reaches 0.2Mpa. The addition amount of oxide scale is 3kg / t semi-steel, and the addition amount of dephosphorization agent is 4kg / t semi-steel. After the semi-steel has been delivered, it is hoisted to th...

Embodiment 2

[0034] The amount of molten iron in the molten iron package is 161 tons, and the composition of the molten iron is shown in the table below:

[0035]

[0036] First, hoist it to the desulfurization station for desulfurization treatment. The desulfurization results and process parameters are shown in the following table:

[0037]

[0038] The molten iron after desulfurization is mixed into the vanadium extracting converter, and 14 tons of iron nuggets are added to carry out blowing with oxygen supply. The process control and end point are as follows:

[0039]

[0040] Then carry out semi-steel tapping operation (the semi-steel tapping volume is 167 tons), the semi-steel tapping time is 5 minutes, and the working pressure of nitrogen blowing at the bottom of the ladle reaches 0.2Mpa. The addition amount of oxide scale is 4kg / t semi-steel, and the addition amount of dephosphorization agent is 5kg / t semi-steel. After the semi-steel is delivered, it is hoisted to the slag...

Embodiment 3

[0044] The amount of molten iron in the molten iron package is 162 tons, and the composition of the molten iron is shown in the table below:

[0045]

[0046] First, hoist it to the desulfurization station for desulfurization treatment. The desulfurization results and process parameters are shown in the following table:

[0047]

[0048] Then blend into the vanadium extracting converter, add 18 tons of iron block, and carry out oxygen blowing. The process control and end point are as follows:

[0049]

[0050] Then carry out semi-steel tapping operation (the semi-steel tapping volume is 169 tons), the semi-steel tapping time is 6 minutes, and the working pressure of nitrogen blowing at the bottom of the ladle reaches 0.3MPa. The addition amount of oxide scale is 5kg / t semi-steel, and the addition amount of dephosphorization agent is 6kg / t semi-steel. After the semi-steel is delivered, it is hoisted to the slag removal station for slag removal treatment, and then samp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com