Semisteel steelmaking method

A technology of molten steel and ladle, applied in the manufacture of converters, etc., which can solve the problems of low yield of recarburizer, instability, and low tapping temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

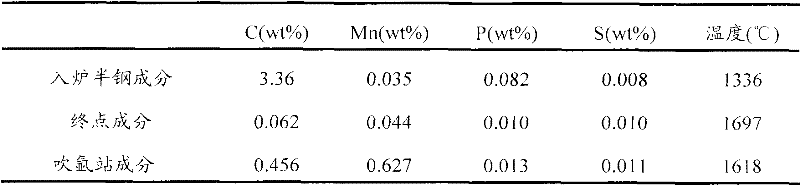

[0052] Use semi-steel after desulfurization and vanadium extraction as raw material to smelt No. 45 high-quality carbon structural steel. The main components of the semi-steel used in Example 1 are shown in Table 1.

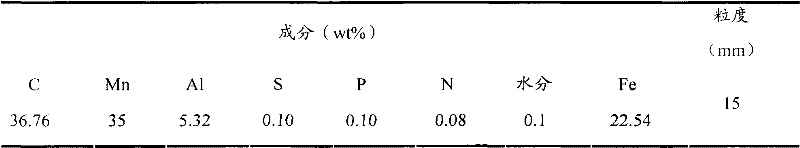

[0053] Blowing with a 120t compound blowing converter, after the semi-steel is mixed into the converter, the oxygen lance is lowered to start blowing oxygen, the oxygen blowing pressure is 0.9Mpa, and the oxygen supply intensity is 3.6m 3 / t 钢 .min; while starting to blow oxygen, add slagging material active lime, the above-mentioned composite slagging agent and high-magnesium lime into the furnace, and add all the slagging materials within 3 minutes of starting the blowing and oxygen supply, and the slagging material activity The addition amount of lime, composite slagging agent and high magnesium lime is 28Kg / t respectively 半钢 、21Kg / t 半钢 and 15Kg / t 半钢 , when the oxygen supply time was 848 seconds, the oxygen lance was raised to stop the oxygen supply, and t...

example 2

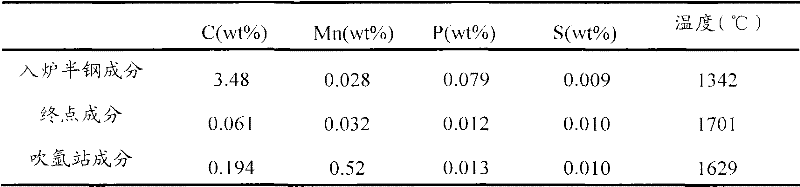

[0060] Use semi-steel after desulfurization and vanadium extraction as raw material to smelt B (PSL1) steel. The main components of semi-steel are shown in Table 3.

[0061] Blowing with a 120t re-blowing converter, after the semi-steel is mixed into the converter, the oxygen lance is lowered to start blowing oxygen, the oxygen blowing pressure is 0.9Mpa, and the oxygen supply intensity is 3.65m 3 / t 钢 .min; while starting to blow oxygen, add slagging material active lime, the above-mentioned composite slagging agent and high-magnesium lime into the furnace, and add all the slagging materials within 3 minutes of starting the blowing and oxygen supply, and the slagging material activity The addition amount of lime, composite slagging agent and high magnesium lime is 30Kg / t respectively 半钢 、23Kg / t 半钢 and 14Kg / t 半钢 , when the oxygen supply time was 825 seconds, the oxygen lance was lifted to stop the oxygen supply, and the molten steel with a temperature of 1701°C was obtaine...

example 3

[0068] Use semi-steel after desulfurization and vanadium extraction as raw material to smelt HRB400. The main components of semi-steel are shown in Table 5.

[0069] Blowing with 120t re-blowing converter, after the semi-steel is mixed into the converter, the oxygen lance is lowered to start blowing oxygen, the oxygen blowing pressure is 0.9Mpa, and the oxygen supply intensity is 3.62m 3 / t 钢 .min; while starting to blow oxygen, add slagging material active lime, the above-mentioned composite slagging agent and high-magnesium lime into the furnace, and add all the slagging materials within 3 minutes of starting the blowing and oxygen supply, and the slagging material activity The addition amount of lime, composite slagging agent and high magnesium lime is 27.5Kg / t respectively 半钢 、18.9Kg / t 半钢 and 14.2Kg / t 半钢 , when the oxygen supply time was 795 seconds, the oxygen lance was lifted to stop the oxygen supply, and the molten steel with a temperature of 1689°C was obtained, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com