Method of producing titanium enriched material using titanium mineral

A titanium-rich material and titanium ore technology, applied in chemical instruments and methods, magnetic separation, solid separation, etc., can solve the problem of no production, and achieve the effect of protecting resources, high resource utilization efficiency, and resource saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

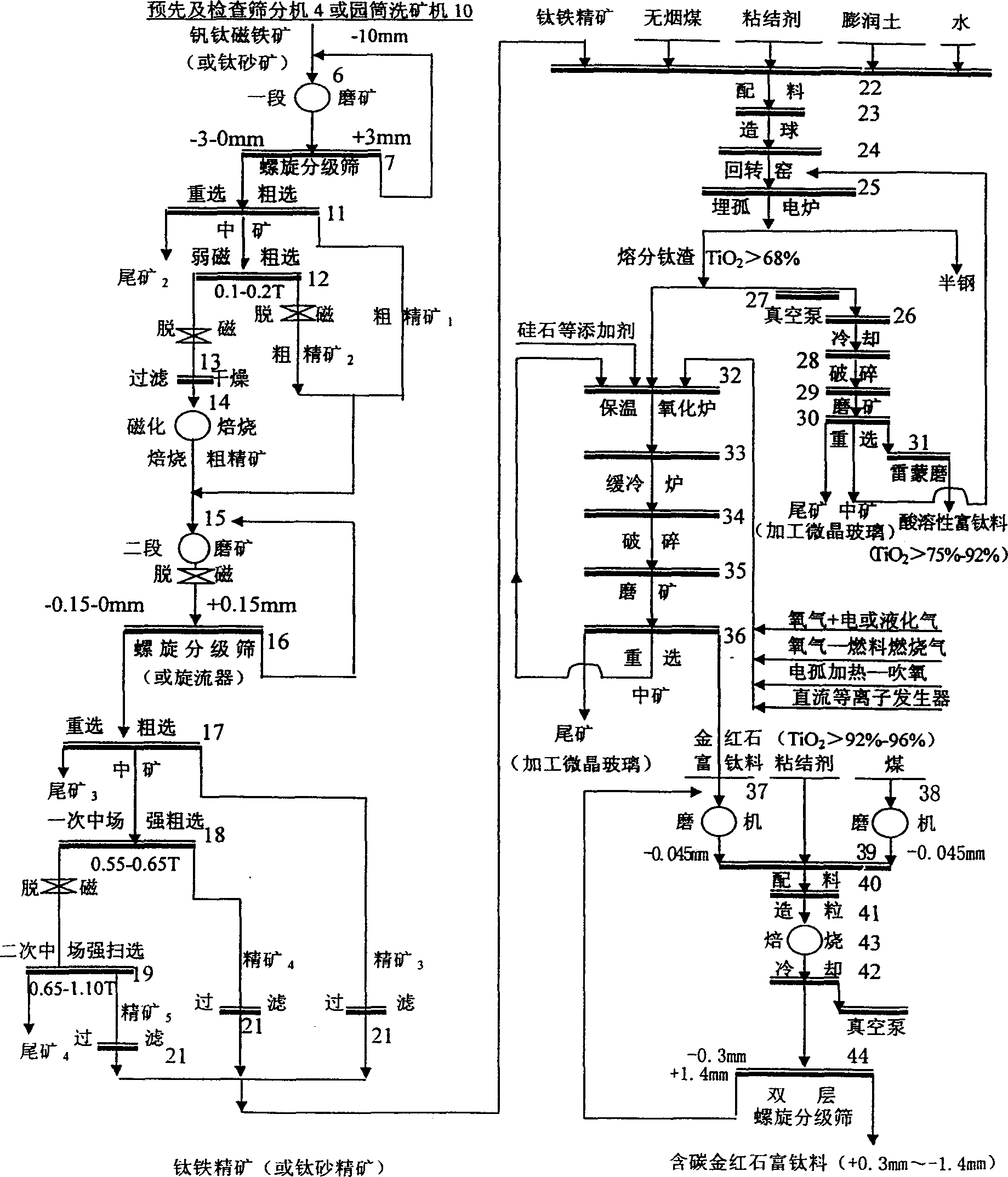

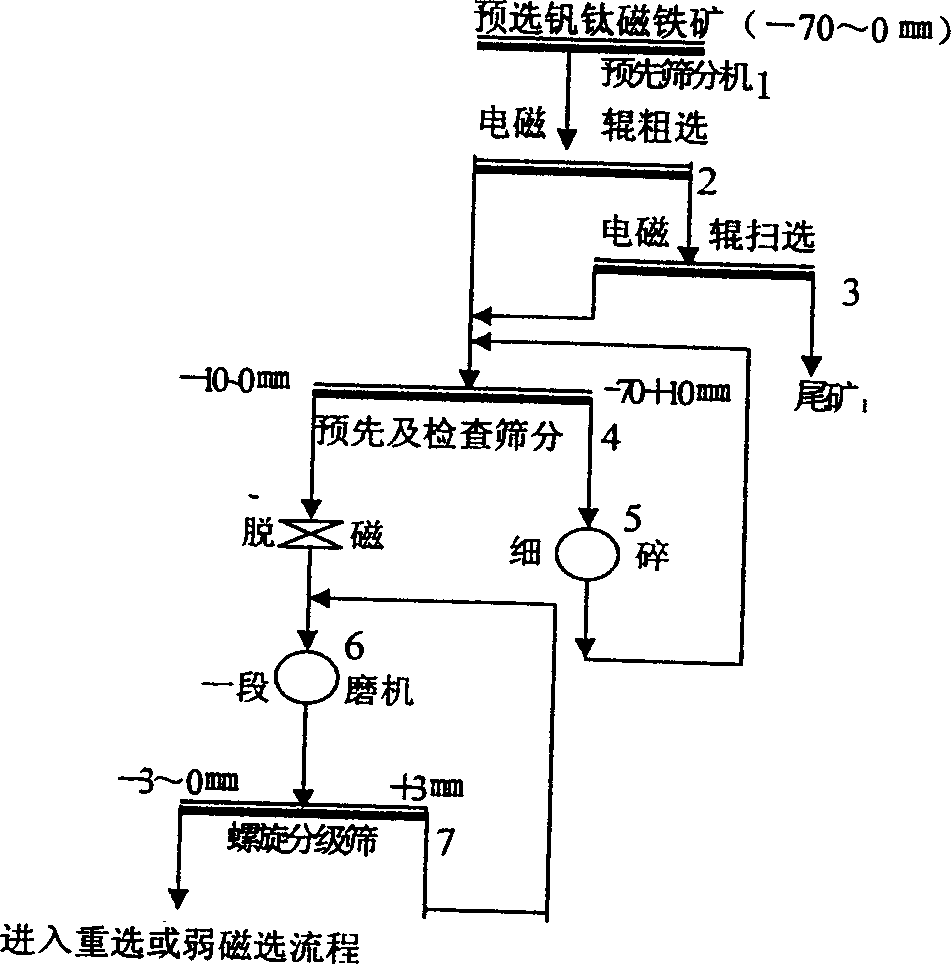

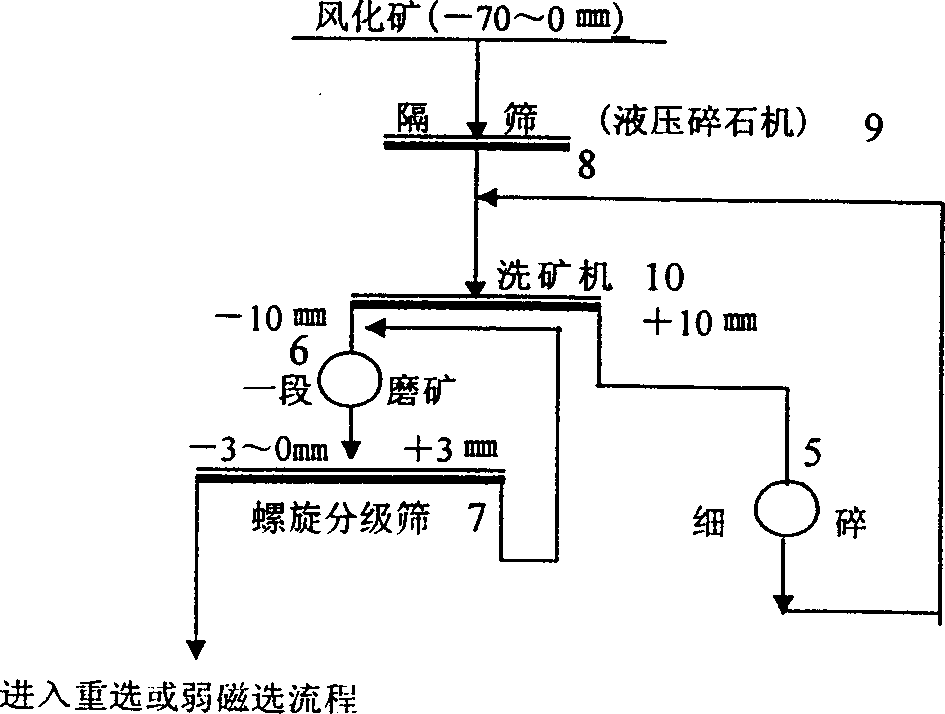

[0022] The present invention will be further described below in conjunction with the drawings and specific embodiments.

[0023] Such as figure 1 , 4 As shown, -70mm titanium ore (vanadium-titanium magnetite, titanium placer) is pre-selected and washed with tailings or weathered ore, and then -10mm ore is ground and beneficiated in the magnetization roasting stage to separate the gangue minerals into ilmenite concentrate (Or titanium sand concentrate), or this ilmenite concentrate (or titanium sand concentrate) and vanadium ilmenite concentrate (or titanium concentrate) are mixed in a certain proportion and then mixed with binder (bentonite, etc.) and carbonaceous After the reducing agent is mixed, the pellets are pre-reduced or directly put into the furnace, and smelted in the electric blast furnace or submerged arc furnace to produce TiO 2 >68% of high-titanium slag (melting titanium slag) and semi-steel (alloy hot metal), the alloy hot metal is blown with vanadium and chromium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com