Semi-steel steelmaking method

A steelmaking furnace and raw material technology, applied in the field of semi-steel steelmaking, can solve problems such as poor dephosphorization and desulfurization effects, and achieve stable dephosphorization and desulfurization effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] This embodiment is used to illustrate the semi-steel steelmaking method provided by the present invention.

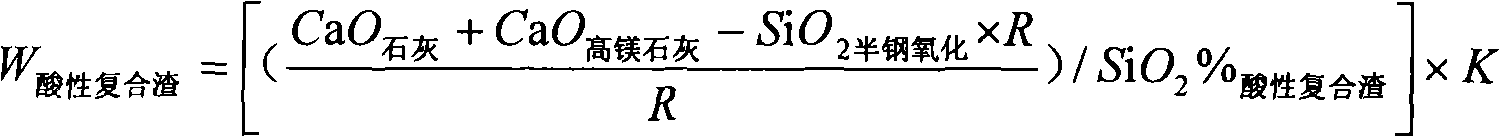

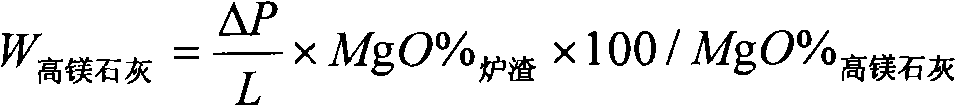

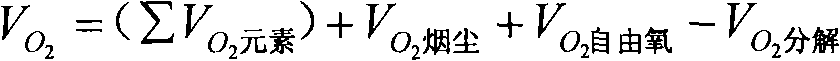

[0056] Add 120 tons of vanadium-extracted semi-steel into the converter for smelting. The composition of the semi-steel is shown in Table 1 below. The furnace temperature is 1350°C. The amount of lime, high-magnesium lime and acidic composite slag added and the amount of oxygen blowing are listed in Table 2 below. Thus, the tapping composition of the X65 steel grade steel obtained by smelting is shown in Table 1 below, and the tapping temperature is 1690°C. Among them, the slag basicity is 3.6, the slagging coefficient is 0.86, the dephosphorization efficiency is 0.89, the weight percent content of MgO in the slag is 10%, the content of MgO in the high magnesium lime is 30% by weight, and the content of CaO in the high magnesium lime is The content of CaO in lime is 52% by weight, the content of CaO in lime is 88% by weight, and the content of SiO in acidic compo...

Embodiment 2

[0063] This embodiment is used to illustrate the semi-steel steelmaking method provided by the present invention.

[0064] Put 120 tons of vanadium-extracted semi-steel into the converter for smelting. The composition of the semi-steel is shown in Table 3 below. The furnace temperature is 1343°C. ) and the amount of oxygen blowing are shown in Table 4 below, so that the tapping composition of the steel of YQ450 steel grade obtained by smelting is shown in Table 3 below, and the tapping temperature is 1698°C. Among them, the slag basicity is 4.2, the slagging coefficient is 0.98, the dephosphorization efficiency is 0.92, the weight percentage of MgO in the slag is 11.2%, the content of MgO in the high magnesium lime is 36% by weight, and the content of CaO in the high magnesium lime is 49% by weight, the content of CaO in lime is 90% by weight, and the content of SiO in acidic composite slag 2 The content is 45% by weight, semi-steel oxidized SiO 2 It is 0.039% of the weight ...

Embodiment 3

[0071] This embodiment is used to illustrate the semi-steel steelmaking method provided by the present invention.

[0072] Add 120 tons of vanadium-extracted semi-steel into the converter for smelting. The composition of the semi-steel is shown in Table 5 below. The furnace temperature is 1333°C. The amount of addition and the amount of oxygen blowing are shown in Table 6 below, so that the tapping composition of the steel that is smelted to obtain the Q235D steel grade is shown in Table 5 below, and the tapping temperature is 1692 °C . Among them, the slag basicity is 4.7, the slagging coefficient is 0.79, the dephosphorization efficiency is 0.94, the weight percent content of MgO in the slag is 12%, the content of MgO in the high-magnesia lime is 40% by weight, and the content of CaO in the high-magnesia lime The content of CaO in lime is 55% by weight, the content of CaO in lime is 85% by weight, and the content of SiO in acidic composite slag 2 The content is 51% by weig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com