Dephosphorization method of semi-steel

A dephosphorization and slagging technology, applied in the field of steelmaking, can solve the problems of low dephosphorization rate of converter, insufficient heat source, slow slagging speed and other problems, achieve high dephosphorization efficiency, reduce steelmaking production cost, and good dephosphorization effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The parameters of the six-hole oxygen lance nozzle of a steel plant are shown in Table 1:

[0029] Table 1 Parameters of six-hole oxygen lance nozzle

[0030] Nozzle type

Number of holes (a)

Angle of nozzle hole (degree)

Mach number

Combination

6 holes around

Φ33

16

2.05

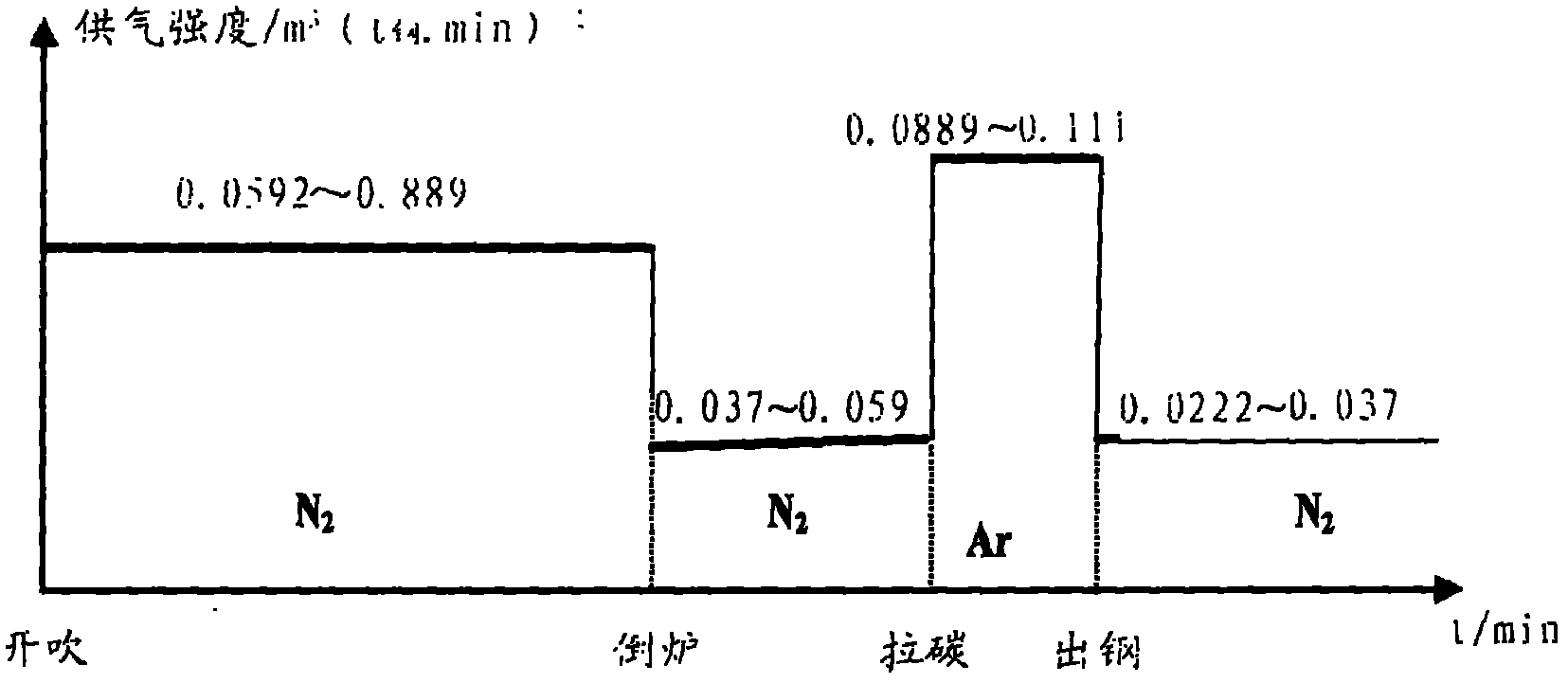

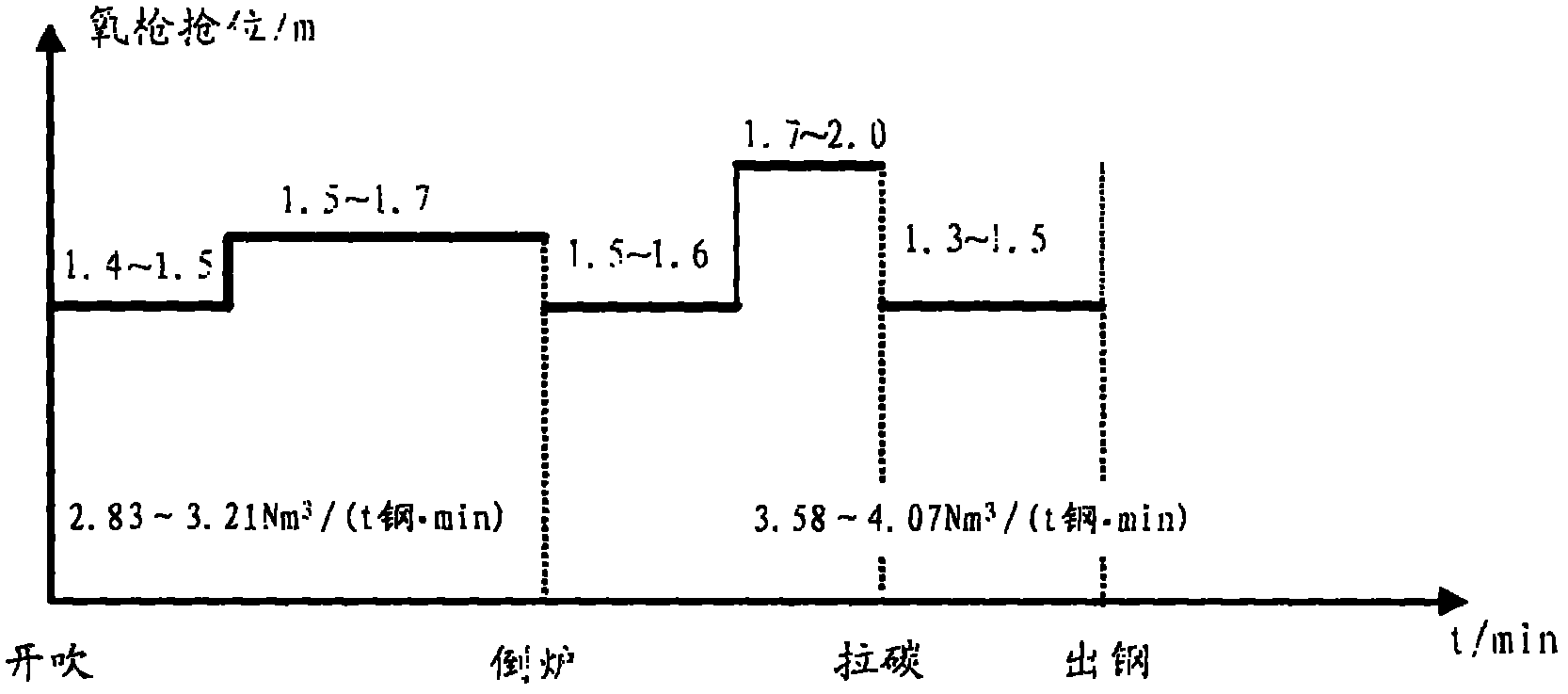

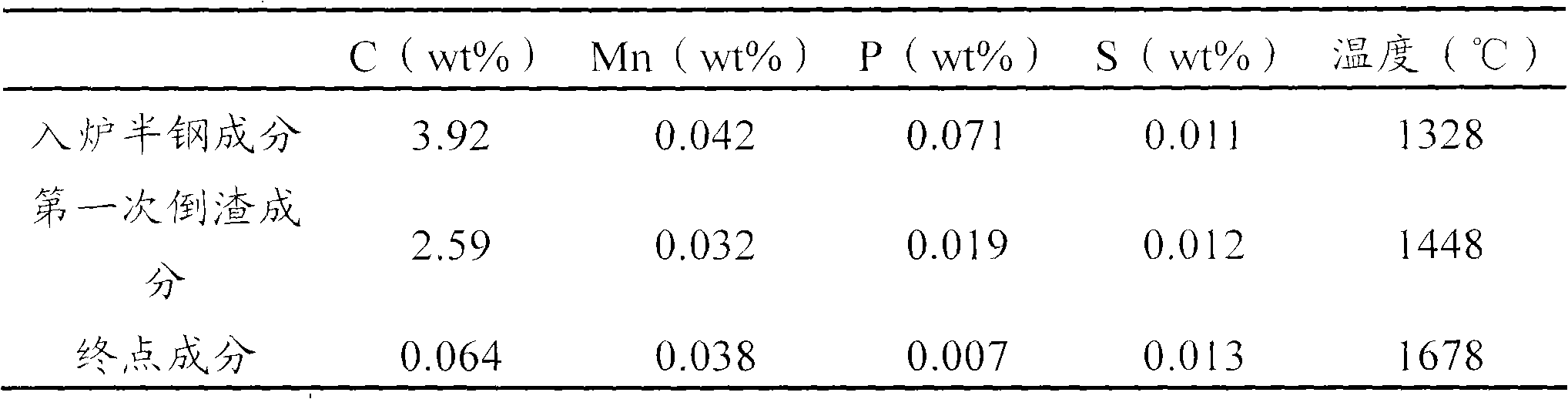

[0031] An oxygen lance with parameters as described in Table 1 was used for smelting on a 120-ton converter in a steel plant. The oxygen flow rate during the initial dephosphorization is 23000Nm 3 / h, working pressure is 0.70MPa, oxygen supply intensity is 2.84m 3 / (t steel·min), the bottom blowing nitrogen flow rate is 100Nm when blowing 3 / h, bottom blowing air supply intensity is 0.0592m 3 / (t steel·min). At this time, the low gun position is mainly used to promote slag removal, and the gun position is 1.4m. The amount of the first batch of slagging materials is: active lime 13kg / t semi-steel; slagging material high-magnesium lime is added 11kg / t semi-steel; slagging...

Embodiment 2

[0036] The parameters of the six-hole oxygen lance nozzle of a steel plant are shown in Table 3:

[0037] Table 3 Parameters of six-hole oxygen lance nozzle

[0038] Nozzle type

Number of holes (a)

Angle of nozzle hole (degree)

Mach number

Combination

6 holes around

Φ32

18

2.08

[0039] A 120-ton converter in a steel plant uses oxygen lances with parameters as described in Table 3 for smelting. The oxygen flow rate during the initial dephosphorization is 25000Nm 3 / h, working pressure is 0.75MPa, oxygen supply intensity is 3.21m 3 / (t steel·min), the bottom blowing nitrogen flow rate is 120Nm when blowing 3 / h, the gas supply intensity is 0.0889m 3 / (t steel·min). The amount of the first batch of slagging material added is: active lime 22kg / t semi-steel; slagging material high-magnesium lime added 20kg / t semi-steel; slagging material composite slagging agent added 22kg / t semi-steel. Add slag conditioning agent in the late stage of the first deph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com