Method for preventing blowing explosion venting of dry dust-removing system of semi-steel steelmaking converter

A steelmaking converter and dry dust removal technology, applied in the manufacture of converters, etc., can solve the problems of reducing the degree of dust collector damage, equipment damage, explosion, etc., to reduce non-production operation time, prolong service life, and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

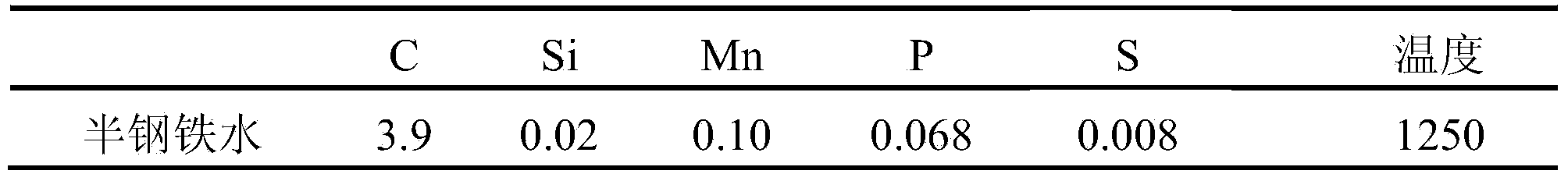

[0039] Semi-steel is smelted on a 180t converter in a steel plant. The semi-steel is molten steel obtained after desulfurization and vanadium-extracting molten iron containing vanadium. The composition and temperature of the semi-steel entering the furnace are shown in Table 1.

[0040] Table 1 Composition (%) and temperature (℃) of semi-steel in furnace

[0041]

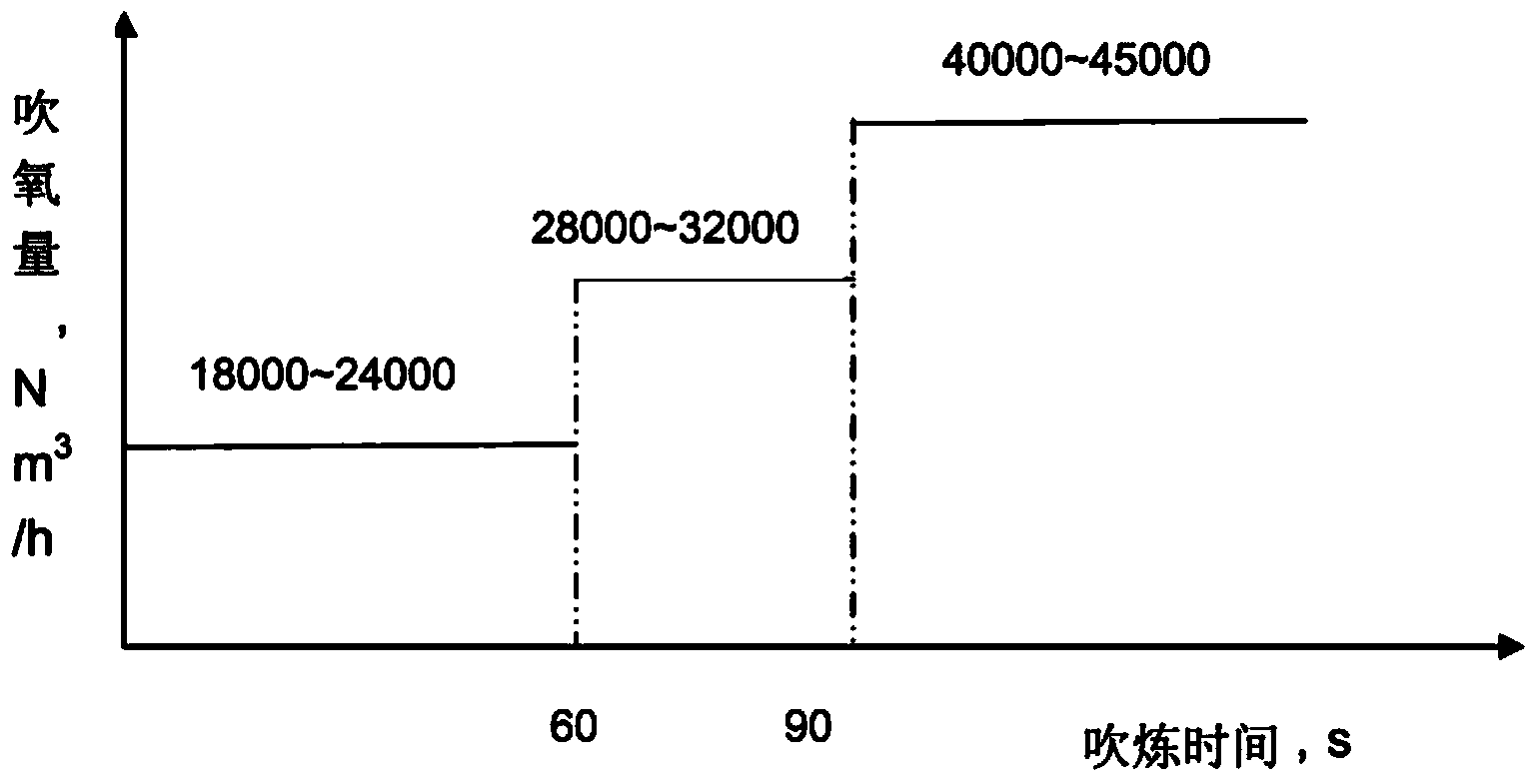

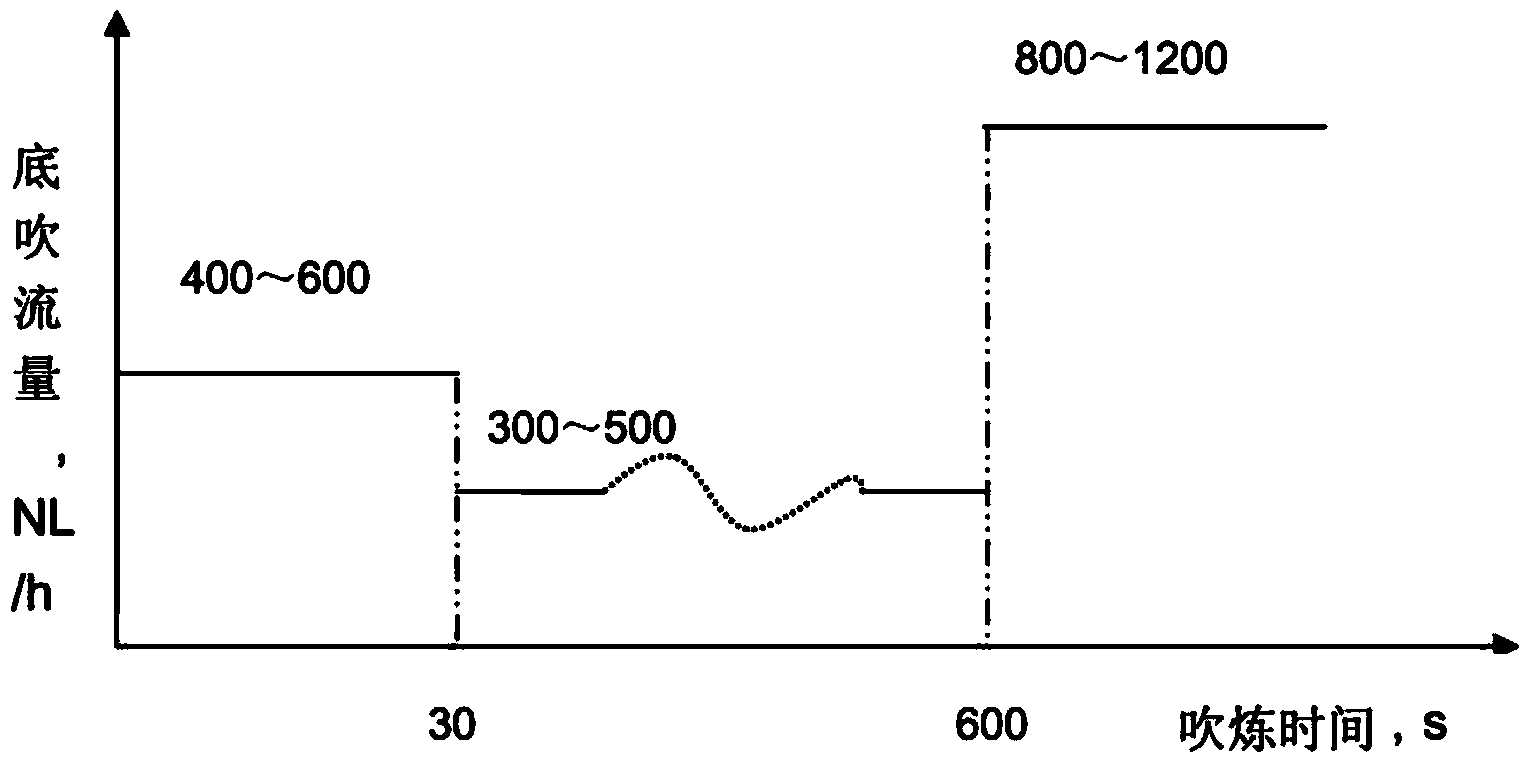

[0042] Among them, there is slag from the previous furnace in the converter, the iron mixing is completed and the blowing is ready to start, and within 0-60s of the converter blowing: adjust the oxygen blowing volume of the top blowing oxygen lance to 20000Nm 3 / h, the gun position of the top blowing oxygen lance is controlled to 2.0m, and the blowing is started; within 30s after the start of the blowing, 42Kg of carbon powder is added from the high-level silo of the converter.

[0043] During blowing 60~90s, control the oxygen blowing volume of the top blowing oxygen lance to 30000Nm 3 / h, the gun position of t...

example 2

[0047] The semi-steel is smelted in a 200t converter in a steel factory. The semi-steel is molten steel obtained after desulfurization and vanadium extraction of vanadium-containing molten iron. The composition and temperature of the semi-steel entering the furnace are shown in Table 2.

[0048] Table 2 Composition (%) and temperature (℃) of semi-steel in furnace

[0049]

[0050] Among them, there is slag from the previous furnace in the converter, and the iron mixing is completed and the blowing is ready to start. Within 0 to 60 seconds of blowing: adjust the oxygen blowing volume of the top blowing oxygen lance to 18000Nm 3 / h, start blowing, the blowing gun position is controlled at 2.2m; within 15s after the start of blowing, add 80Kg of ferrosilicon from the high-level silo of the converter.

[0051] Within 60-90 seconds of blowing, control the oxygen blowing volume of the top blowing oxygen lance to 28000Nm 3 / h, the gun position of the top blowing oxygen lance is c...

example 3

[0055] The semi-steel is smelted on a 250t converter in a steel factory. The semi-steel is molten steel obtained after desulfurization and dephosphorization of molten iron. The composition and temperature of the semi-steel entering the furnace are shown in Table 3.

[0056] Table 3 Composition (%) and temperature (℃) of semi-steel in furnace

[0057]

[0058] Among them, 10t (supplementary amount of added scrap steel) steel scrap is added to the converter. When the iron mixing is completed and the blowing is ready to start, within 0-60 seconds of blowing: adjust the oxygen blowing amount of the top blowing oxygen lance to 23000Nm 3 / h, adjust the gun position to 2.2m to start blowing; within 15s after the start of blowing, add 50Kg of ferrosilicon (or aluminum shot) from the high-level silo of the converter. During blowing 60~90s, control the oxygen blowing volume of the top blowing oxygen lance to 34000Nm 3 / h, gun position control 1.5 ~ 1.6m; after blowing 90s, control t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com