Coolant for dephosphorizing and extracting vanadium of converter, production method thereof, and method for dephosphorizing and extracting vanadium of converter

A production method and coolant technology, applied in the manufacture of converters, etc., can solve problems such as complex steps, and achieve the effects of simple operation, high dephosphorization efficiency, and low-cost converter steelmaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

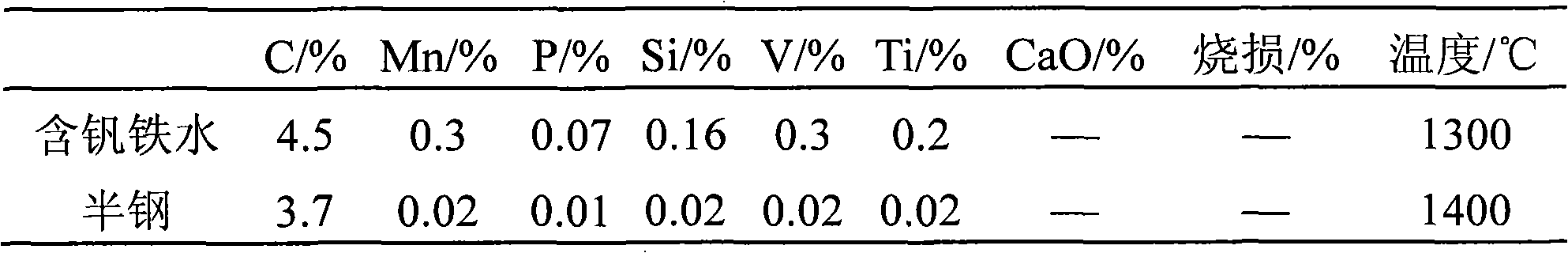

[0038] Vanadium is extracted in a 120-ton converter in a steel plant, and the molten iron charge is 140 tons. During the process of vanadium extraction in the converter, chilled pellets with the function of simultaneous dephosphorization and vanadium extraction are added for simultaneous dephosphorization and vanadium extraction in the converter. For this smelting furnace, the components of vanadium-containing molten iron and semi-steel at the end of blowing and the temperature are shown in Table 1. The remaining components of vanadium-containing molten iron and pig iron block semi-steel are Fe.

[0039] Table 1 Composition of vanadium-containing molten iron and semi-steel composition and temperature at the end of blowing

[0040]

[0041] The ratio of the cold solidified pellet finished product composition with simultaneous dephosphorization and vanadium extraction function is (mass percentage): Na 2 CO 3 : 42%; FeO: 25%; Fe 2 o 3 : 25%; SiO 2 : 4%; Al 2 o 3 : 4%. T...

example 2

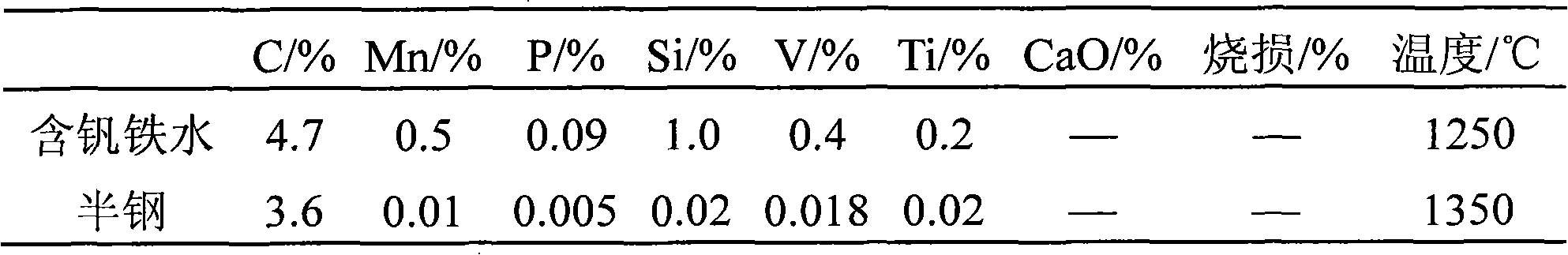

[0044] Vanadium is extracted in a 120-ton converter in a steel plant, and its molten iron load is 145 tons. During the process of vanadium extraction in the converter, cold solidified pellets with the function of simultaneous dephosphorization and vanadium extraction are added for simultaneous dephosphorization and vanadium extraction in the converter. For this smelting furnace, the composition and temperature of the vanadium-containing molten iron and semi-steel at the end of blowing are shown in Table 2. The remaining components of the vanadium-containing molten iron and pig iron block semi-steel are Fe.

[0045] Table 2 Composition of vanadium-containing molten iron and semi-steel composition and temperature at the end of blowing

[0046]

[0047] The ratio of the cold solidified pellet finished product composition with simultaneous dephosphorization and vanadium extraction function is (mass percentage): Na 2 CO 3 : 45%; FeO: 20%; Fe 2 o 3 : 30%; SiO 2 : 2%; Al 2 o ...

example 3

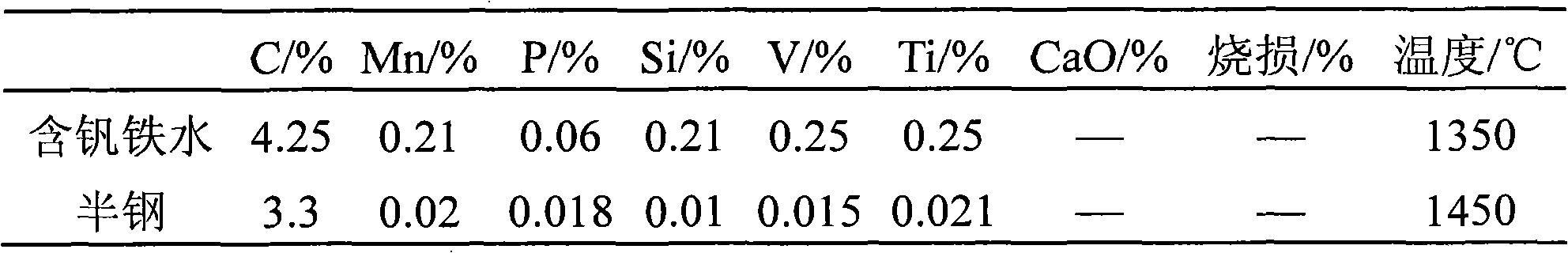

[0050] Vanadium is extracted in a 120-ton converter in a steel plant, and its molten iron load is 135 tons. During the process of vanadium extraction in the converter, cold solidified pellets with the function of simultaneous dephosphorization and vanadium extraction are added for simultaneous dephosphorization and vanadium extraction in the converter. For this smelting furnace, the components of the vanadium-containing molten iron and the composition and temperature of the half-steel at the end of blowing are shown in Table 3. The remaining components of the vanadium-containing molten iron and pig iron block semi-steel are Fe.

[0051] Table 3 Composition of vanadium-containing molten iron and semi-steel composition and temperature at the end of blowing

[0052]

[0053] The ratio of the cold solidified pellet finished product composition with simultaneous dephosphorization and vanadium extraction function is (mass percentage): Na 2 CO 3 : 35%; FeO: 30%; Fe 2 o 3 : 25%;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com