Dephosphorization process for high phosphorous molten iron

A technology of molten iron and process, applied in the direction of improving process efficiency, manufacturing converters, etc., can solve problems such as inability to handle high-phosphorus molten iron

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Put 20kg of pig iron into a 50kg intermediate frequency induction furnace. The top of the induction furnace is equipped with an oxygen lance that can be lifted freely, and the bottom of the furnace is equipped with slit-type ventilation bricks, which have the function of simulating top-blowing and bottom-blowing compound blowing. Raise the temperature to melt the pig iron, blow nitrogen into the bottom, and raise the temperature to 1300°C after melting to carry out the thermal simulation experiment.

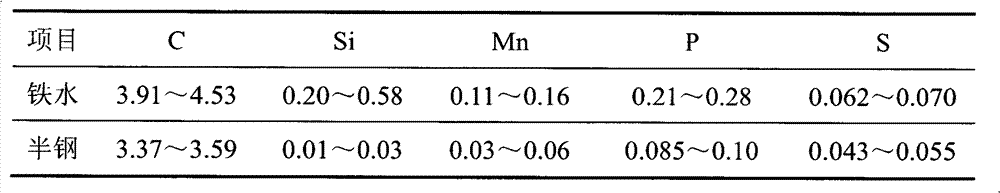

[0020] After the test started, oxygen was blown by lowering the gun, and scrap steel and pre-mixed slag were added at the same time. The amount of scrap steel added was 15% of the molten iron, and the slag was lime and dephosphorization agent. The first batch of slag was 70% of the total slag. %, then add the remaining slag in batches, adjust the flow rate of the bottom blowing gas to the value equivalent to the stirring energy of 3KW / t, see Table 1 for the composition of m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com