Single-step metallurgical flash furnace and metallurgical method

A flash furnace and metal ore technology, applied in electric furnaces, crucible furnaces, rotary drum furnaces, etc., can solve the problems of difficult slag discharge, high iron content in products, complex process flow, etc., to achieve low production costs and comprehensive recovery. Exploiting, wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

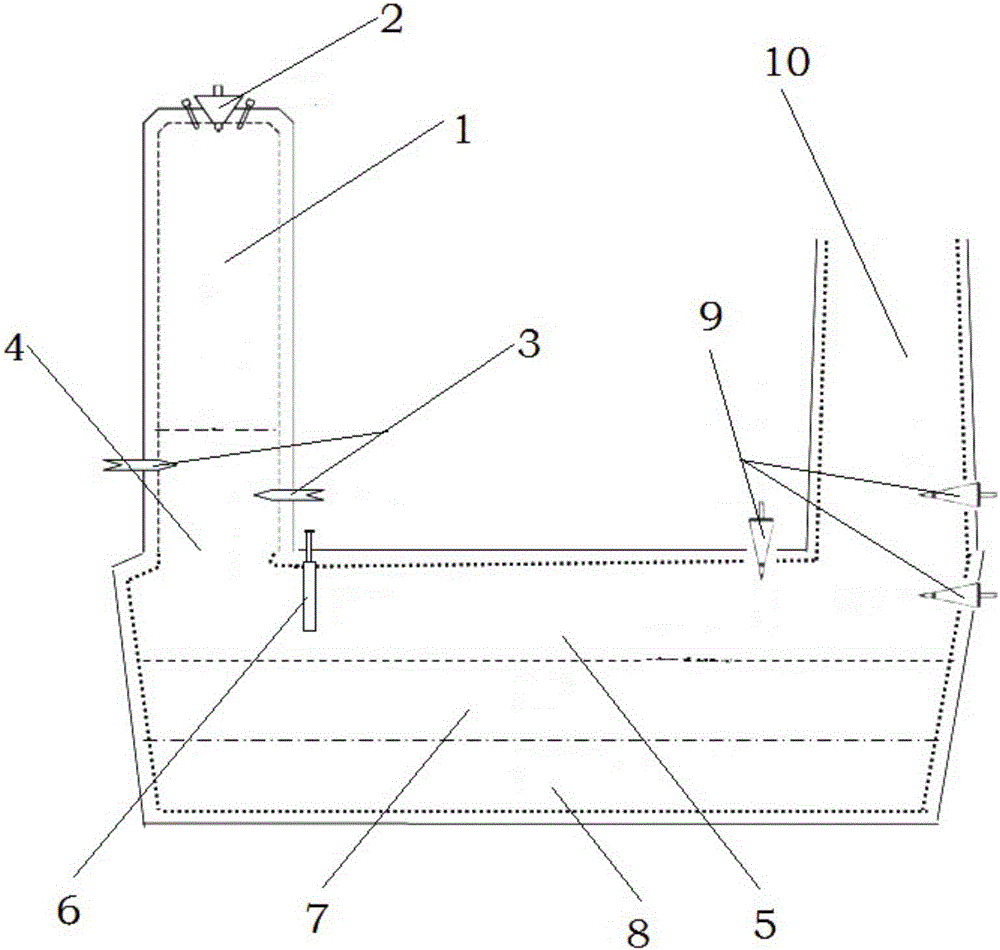

[0034] The flash furnace of embodiment 1 one-step metallurgy

[0035] A flash furnace for one-step metallurgy, comprising a reaction tower 1, a nozzle 2 is arranged on the top of the reaction tower 1; one end of the molten pool 5 is connected to the lower part of the reaction tower 1, and an ascending flue 10 is arranged above the other end of the molten pool 5; the reaction tower 1 The lower part is equipped with a gas introduction device 3 for introducing reducing gas, which contains CO and H 2 . The reducing gas forms a reducing gas cushion 4 in the lower part of the reaction tower 1 and the upper space of the molten pool 5 . A retaining wall 6 is provided at the joint between the molten pool 5 and the reaction tower 1 . A number of spray guns 9 are arranged on the upper part of the melting pool 5 , on the side and on the ascending flue 10 .

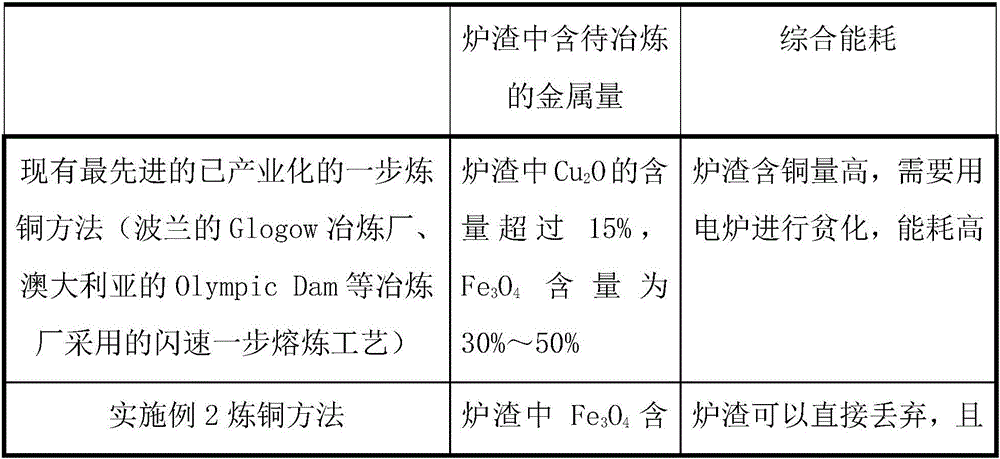

Embodiment 2

[0036] Embodiment 2 Utilizes the method for one-step copper smelting in the flash furnace of embodiment 1

[0037] 1. Preparation of raw materials and auxiliary materials

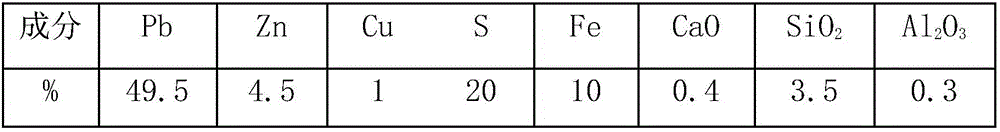

[0038] The raw material used in this embodiment is a kind of imported copper concentrate, and the main components are as follows:

[0039] Element

Cu

S

Fe

SiO 2

CaO+MgO

%

29.5

31

26

6

1

[0040] The raw material is dried and bulked into a dry concentrate with a water content below 0.3% and a particle size below 200 mesh, accounting for 80%.

[0041] Flux is SiO 2 For quartz powder with a content of more than 90%, 90% of the quartz powder has a water content of less than 1% and a particle size of less than 60 mesh. Here, the quartz powder is used as a flux to participate in the slagging process of flash smelting.

[0042] The cold material is one or more of soot, slag, raw ore, and wet leaching slag containing valuable metals such as gold, sil...

Embodiment 3

[0071] Embodiment 3 Utilize the method for the flash furnace of embodiment 1 to smelt nickel-copper crude alloy in one step

[0072] 1. Preparation of raw materials, fuels and auxiliary materials

[0073] The raw material is nickel concentrate, which mainly contains nickel and copper. The mass ratio of nickel and copper is usually between 1.5 and 2.5. In addition, it also contains cobalt and a small amount of gold, silver and platinum group metals. The composition of the nickel concentrate that present embodiment adopts is as follows:

[0074] Element

Ni

Cu

co

Fe

S

SiO 2

CaO

MgO

%

6.6

2.8

0.3

39.5

27.3

8.2

1.2

6

[0075] The raw material is dried and bulked into a dry concentrate with a water content below 0.3% and a particle size below 200 mesh, accounting for 80%.

[0076] Flux is SiO 2 For quartz powder with a content of more than 90%, 90% of the quartz powder has a water content of le...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com