Debris removing device for glass fragments

A technology for glass fragments and cleaning boxes, applied in lighting and heating equipment, cleaning methods and utensils, drying and other directions, can solve the problems of reducing the production capacity of high-temperature furnaces, scrapping high-temperature furnaces, and wasting fuel, so as to facilitate reuse and reduce iron The effect of quality content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

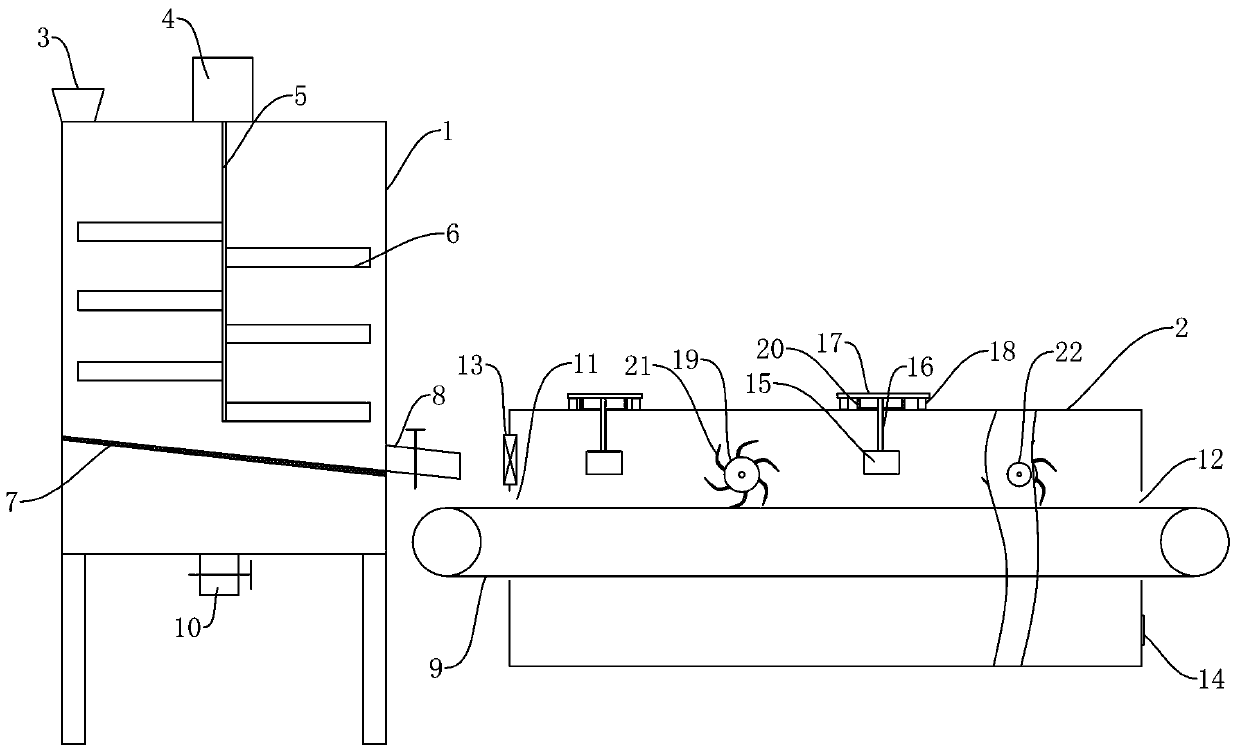

[0016] Such as figure 1 As shown, a glass debris removal device includes a cleaning box 1 and a drying box 2. The upper end of the cleaning box 1 is provided with a feeding port 3 and a stirring motor 4. The stirring motor 4 is a reduction motor, and the output end of the stirring motor 4 is connected to the stirring The shaft 5 is connected, the stirring shaft 5 extends into the cleaning box 1, the stirring shaft 5 is provided with a stirring blade 6, the lower end of the cleaning box 1 is provided with a filter screen 7, and the side wall of the cleaning box 1 is provided with a discharge port opposite to the filter screen 7 8. The discharge port 8 is provided with a valve, the discharge port 8 is set above the starting end of the conveyor 9, the bottom of the cleaning box 1 is provided with a drain port 10; the drying box 2 is provided with an inlet 11 and an outlet for the conveyor 9 to pass through 12. One end of the drying box 2 is equipped with a hot air blower 13, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com